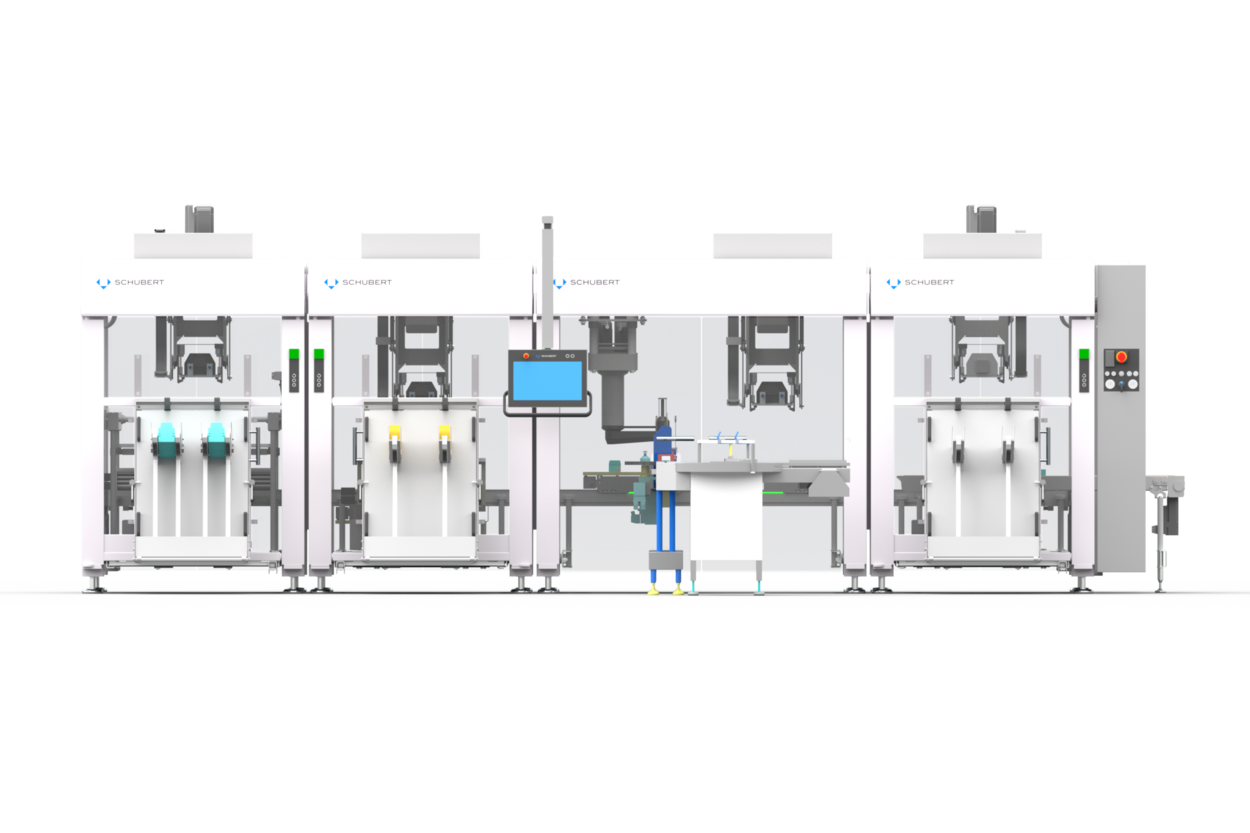

End-to-end turnkey solutions -

covering product feeding, secondary and tertiary packaging and palletizing

Precision. Flexibility. Safety.

Packaging solutions for the pharmaceutical industry demand the highest standards.

We develop modular top-loading machines for the secondary packaging process – designed to meet the requirements of regulated markets:

Our systems handle folding cartons, trays and special formats with reliability and gentle product handling. Thanks to well-engineered interfaces and high modularity, they can be seamlessly integrated or flexibly scaled.

Together, we will find the right solution for your product.

End-to-end turnkey solutions -

covering product feeding, secondary and tertiary packaging and palletizing

Single solution. Complete solution. Turnkey.

Our machines – cartoners, case packers and palletizers – can be operated individually or combined into a complete solution.

All components come from a single source and are precisely matched in terms of technology.

If additional upstream processes - such as infeeds, buffers, labellers, or inspection systems - not manufactured by Schubert need to be integrated, we take full responsibility for the overall system.

In such projects, we deliver a turnkey packaging solution that includes:

For you, this means:

Our reliable packaging solutions for pharmaceutical customers are based on a modular machine architecture and proven standard components. This enables precise planning and implementation of individual packaging tasks.

With our robot-supported TLM technology, we cover a broad spectrum of processes and functions. By seamlessly integrating individual functional units and other machines, we minimize interfaces and deliver a consistently stable, reliable, and secure packaging process.

Top-loading packaging systems enable particularly gentle and precise product handling – a decisive advantage in pharmaceutical production.

With vertical loading, different packaging materials can be processed efficiently, formats can be changed flexibly, and sensitive products such as vials, ampoules or syringes can be positioned securely.

In combination with our robots, vision systems ensure high packaging quality and maximum line availability with the top-loading principle. The systems are fully validatable, modularly expandable and optimally adaptable.

Schubert stands for well-designed and future-proof packaging technology, specifically developed for regulated industries such as pharmaceuticals. Our modular machine platform enables customized solutions with a high level of integration – from primary handling and secondary packaging through to serialization.

In pharmaceutical packaging projects, you benefit from our many years of experience in GMP-compliant project execution, a reliable qualification concept and a dedicated pharma team within the Schubert Group.

We also provide industry-specific training programs for operators, technicians and quality assurance teams. These sessions can take place either directly at your site or at our training centers.

In addition, we support your production with digital services such as remote maintenance, spare parts management and suitable software tools – ensuring that your pharmaceutical production remains stable, maintainable and future-ready.

Our success stories demonstrate how Schubert technology proves its value in practice. The solutions presented here have been successfully implemented at national and international pharmaceutical companies.

Discover how we have reliably solved complex packaging requirements and sustainably optimized processes in concrete customer projects. Each success story provides insights into real applications of our technology and highlights the added value our systems deliver for pharmaceutical packaging.

Take inspiration from our implemented solutions

and contact us – together we will develop the

perfect solution for your product.

Nurdan Aktas

Sales Assistant Pharma

phone +49 7951 494-20

info@schubert-pharma.com