BFS-Product packaging

- Inline with the BFS production system or offline processes possible

- Process steps such as feeding or singulation, labeling of BFS products, flow wrapping, cartoning, case packing, and palletizing

- Compact machine layouts, even for complex shapes

- Quality control and serial number tracking

- Reproducible processes for high output

Special features of BFS

Blow-Fill-Seal (BFS) products often vary greatly in size and geometry. Schubert offers flexible packaging solutions that can be precisely adapted to different BFS formats, enabling safe handling and efficient further processing.

1. Infeed: BFS product

1. Infeed: BFS product

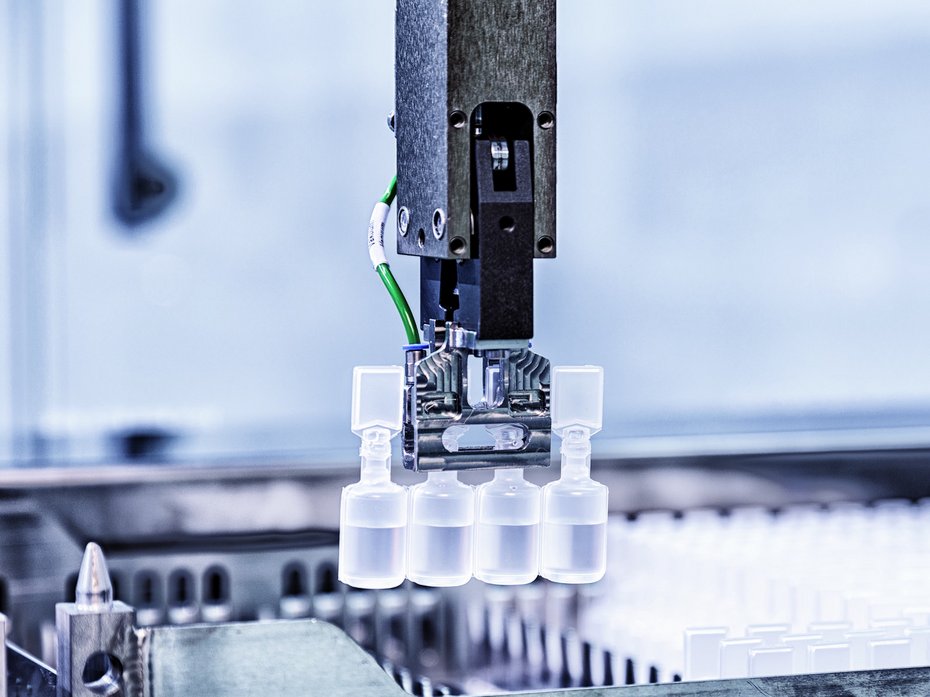

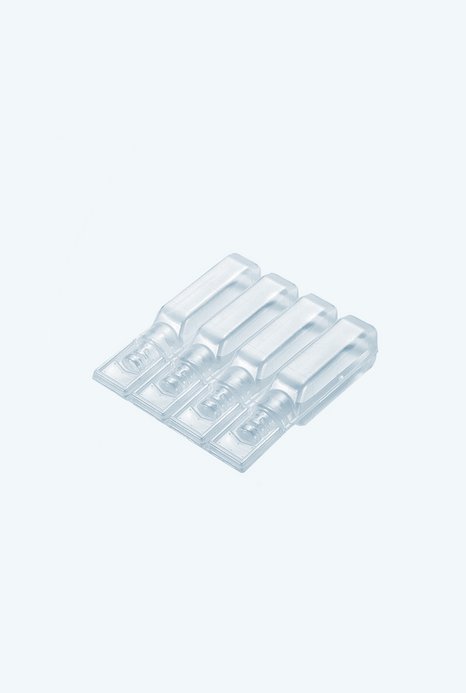

The BFS products are fed individually into 4-position pucks on an infeed conveyor of the machine.

2. Form: Carton

2. Form: Carton

Flat cartons are stored in a magazine. A TLM-F3 robot picks up the flat blank from the magazine and presents it to the TLM-F2 robot. In the meantime, the code on the blank is read and, if necessary, rejected. The TLM-F2 robot then passes the blank over the glue nozzles and presses it through a forming die, thereby erecting the carton. The erected carton is placed on a Transmodul at a defined angle, simplifying the loading process.

3. Load: BFS product

3. Load: BFS product

A TLM-F2 robot picks up the products from the product carrier and transfers them to a second TLM-F2 robot. During this handover step, the Blow-Fill-Seal products are rotated 180° and passed to the loading robot in the desired orientation. The loading robot then spreads the product row to the required number of ampoules per row in the carton.

4. Print: Folding cartons

4. Print: Folding cartons

An inkjet printer applies a Data-Matrix-Code (DMC), lot number, and expiry date onto the erected cartons.

5. Infeed / Load: Package inserts

5. Infeed / Load: Package inserts

The package inserts are stored in a magazine. A TLM-F2 robot picks up the folded package inserts from the magazine and places them onto the products in the erected carton, provided the code verification was successful.

6. Close: Carton

6. Close: Carton

Another TLM-F2 robot folds the carton’s side flaps and seals it directly on the Transmodul. The sealed carton is then transferred to the discharge conveyor.

7. Discharge: Carton

7. Discharge: Carton

The sealed carton leaves the machine in a single lane via a discharge conveyor and is transported onward to a Schubert case packer.

Facts about the

BFS Transfer Unit

From a customer project:

- 540 single ampoules per minute

- 135 four-pack ampoules per minute

- Ampoule sizes: 3 ml and 5 ml

- Format sizes: 25ct and 30ct

- Infeed on product carriers / pucks

- Products rotated 180°

- Connected BFS blocks mechanically separated in an upstream process step (Schubert)

- Products tested for tightness (vacuum inspection) in an upstream process step

Questions about

BFS packaging?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com