Syringes packaging

- Compatible with various syringe sizes and multiple pack configurations possible (single-count to multi-count)

Loading into trays or partitions for optimal product protection

Stacking of trays possible for bulk packaging

- GMP-compliant machine design

- High throughput with secure product protection

Special features of syringes

Syringes must be packaged precisely, hygienically, and often combined with additional accessories. Our top-loading machines enable precise product handling and can be modularly adapted to different packaging requirements.

1. Infeed and group Syringes

1. Infeed and group Syringes

2. Erect carton

2. Erect carton

3. Load syringe and inserts into carton

3. Load syringe and inserts into carton

4. Erect inserts

4. Erect inserts

5. Load leaflet

5. Load leaflet

6. Close carton

6. Close carton

7. Label carton

7. Label carton

8. Discharge carton

8. Discharge carton

1. Infeed: Syringes

1. Infeed: Syringes

The syringes are automatically fed into the machine. Alternatively, manual feeding is also possible, for example in rework processes. The syringes enter the machine in a vertical orientation and are tilted 90° by a TLM-F2 robot, then placed horizontally on a rotary table in formations.

2. Pre-grouping: Syringes

2. Pre-grouping: Syringes

A TLM-F2 robot picks up the syringes and places them onto the format plate of the Transmodul. The remaining syringes on the rotary table are rotated 180°, picked up, and also transferred onto the format plate of the Transmodul. This creates a head-to-tail formation, in which the syringes are transported to the filling station.

3. Form: Cartons

3. Form: Cartons

Flat cartons are stored in a magazine. A TLM-F3 robot picks up a flat blank from the magazine and presents it to the TLM-F2 robot. The TLM-F2 robot places the blank onto the vacuum transport system (VT). Another TLM-F2 robot then passes the blank over the glue nozzles and presses it through a forming die. This erects the carton, while the side flaps initially remain unfolded.

4. Form: Compartments

4. Form: Compartments

A TLM-F3 robot picks up the flat partition from a magazine and presents it to a TLM-F2 robot. The TLM-F2 robot places the blank on the vacuum transport system, folds it at the appropriate position, and inserts the partition into the erected carton.

5. Load: Syringes

5. Load: Syringes

Another TLM-F2 robot takes the pre-grouped syringes (head-to-tail) and places them into the cartons (into the compartments).

6. Verification: Carton contents

6. Verification: Carton contents

A Schubert camera inspects the carton contents once again for completeness. Cartons that do not meet the specifications are rejected in the next step.

7. Load: Package insert

7. Load: Package insert

A TLM-F3 robot picks up the package inserts from an eight-lane magazine and presents them to the TLM-F2 robot. The TLM-F2 robot places the inserts onto the syringes in the carton. At the same time, the side flaps of the cartons are folded in and glued.

8. Close: Lid

8. Close: Lid

The separate flat lids are stored in a magazine. A TLM-F3 robot hands the flat blanks to a TLM-F2 robot. The TLM-F2 robot passes the blank over the glue nozzles and forms it directly around the erected carton, thereby closing the carton.

9. Label / Laser: Carton

9. Label / Laser: Carton

In the final step, a Data Matrix code is printed on the carton and a label is applied.

10. Discharge: Carton

10. Discharge: Carton

The closed carton leaves the machine via a discharge conveyor.

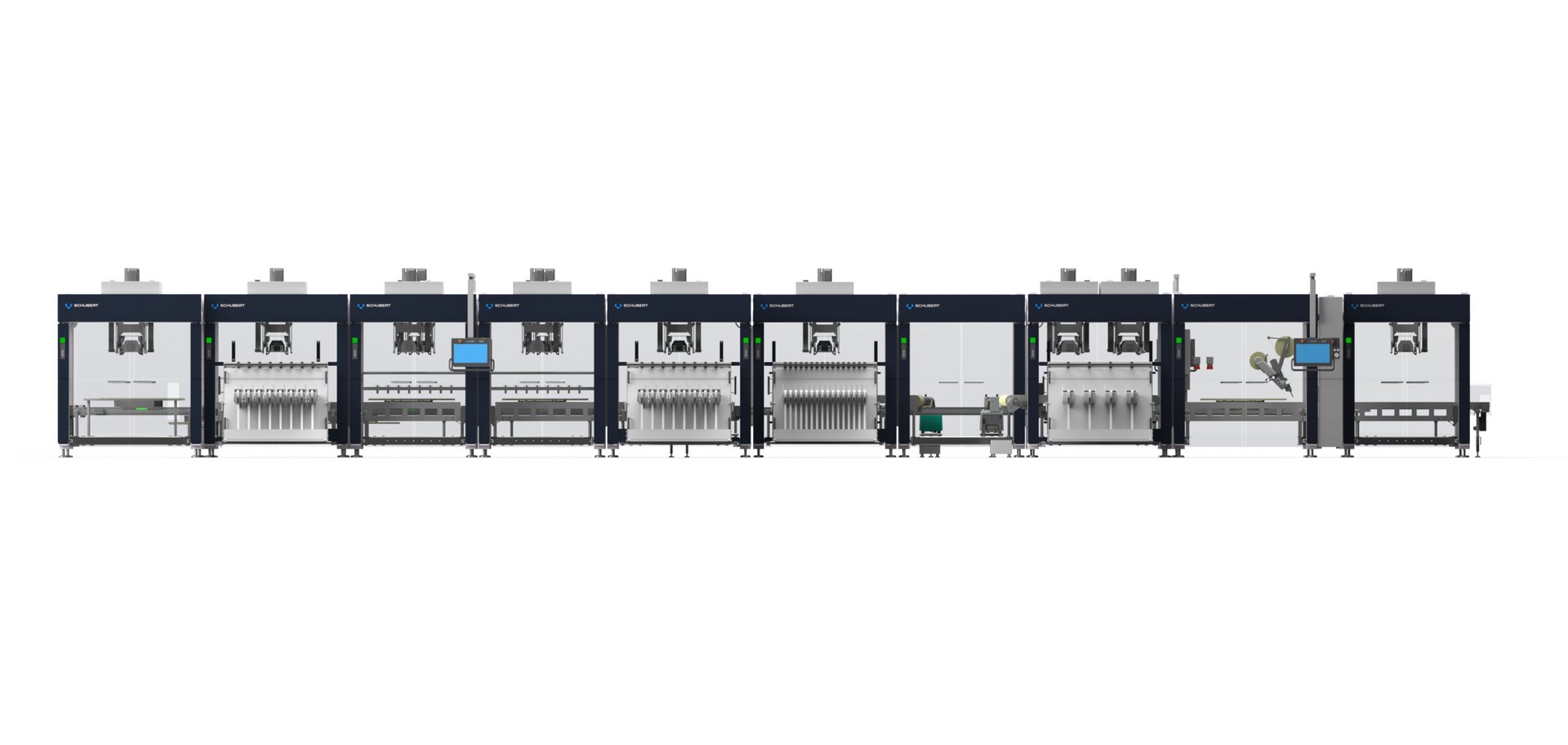

Facts about the

Syringe Cartoner

From a customer project:

- 1ct and 10ct packaging options

- Up to 400 syringes per minute

- Up to 400 single packs per minute or up to 40 ten packs per minute

- Precise loading into partitions

- Leaflet included in each pack

Questions about

Syringe packaging?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com