#SuccessStory #Syringes Innovative Feeding System for a Safe and Efficient Packaging Process at a Pharmaceutical Manufacturer

- Interchangeable format parts allow flexible adaptation to any syringe format

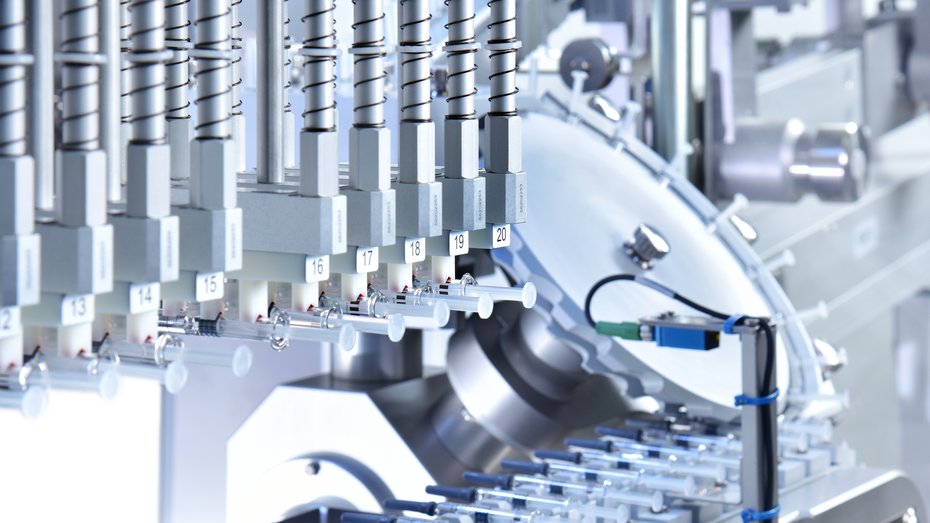

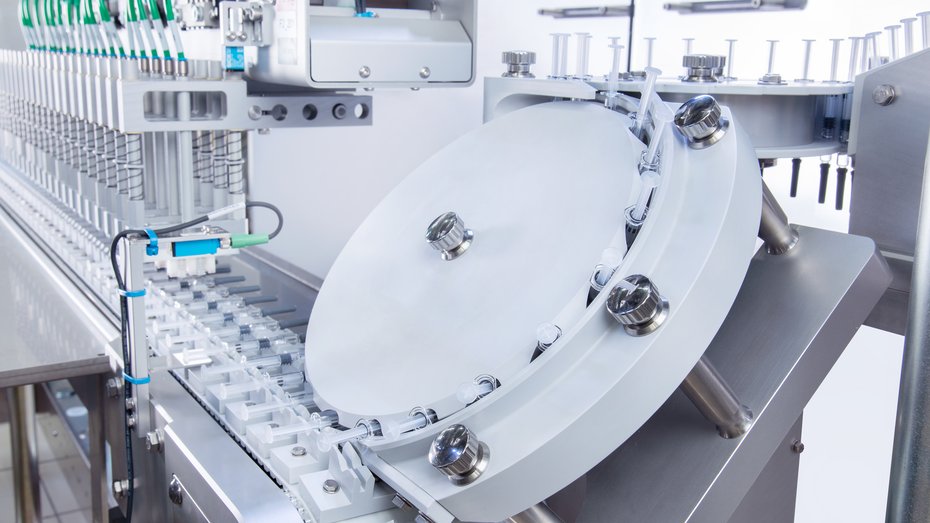

- Interlocking star wheels ensure precise syringe feeding

- Schubert camera system enables fully automated quality control

400

Products per minute

2

Formate

Requirement

Safely processing 400 syringes per minute across the entire production line

As flu season approaches, annually updated vaccines targeting the latest influenza virus strains must be made available in millions of doses within a very short timeframe. To accelerate and secure the biannual ramp-up of its flu vaccine production, a large international pharmaceutical company partnered with Schubert-Pharma. With high-performance star wheels and advanced robotics, the innovative feeding system of the packaging machine manufacturer enables high throughput while ensuring extremely gentle product handling.

The production process is required twice a year because flu seasons in the Northern and Southern Hemispheres occur at different times. Speed is critical: given the lead time needed to adapt vaccines to new virus strains, only a short period remains between the development of the appropriate vaccine and the flu wave. Furthermore, the valuable vaccine doses are filled into different types of glass syringes, requiring a gentle packaging process to prevent damage to the fragile glass.

Previously, pick-and-place robots handled this task, feeding loose syringes in batches of five from opposite sides into trays. Beyond significantly increasing processing speed, the pharmaceutical manufacturer prioritized gentle product handling and prevention of glass breakage—achieving higher throughput without increasing rejects was essential.

Solution

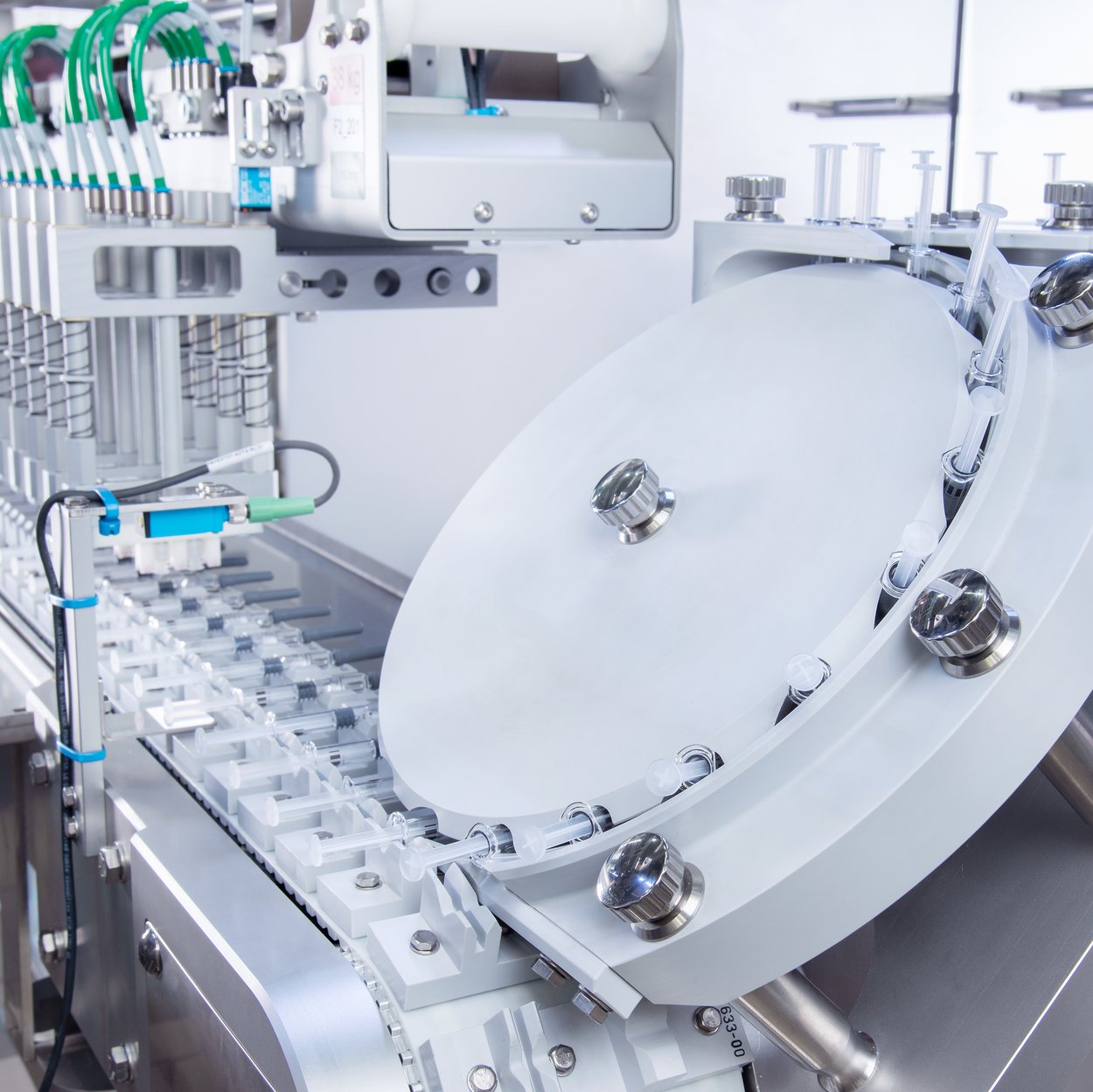

To meet the requirement of safely and gently processing up to 400 syringes per minute, the pharmaceutical company turned to the experts at Schubert-Pharma. Together with the customer, the team developed an exceptionally gentle yet highly efficient solution. The heart of the new system is the feeding section, featuring two interlocking star wheels and pre-grouping on a specialized grouping table.

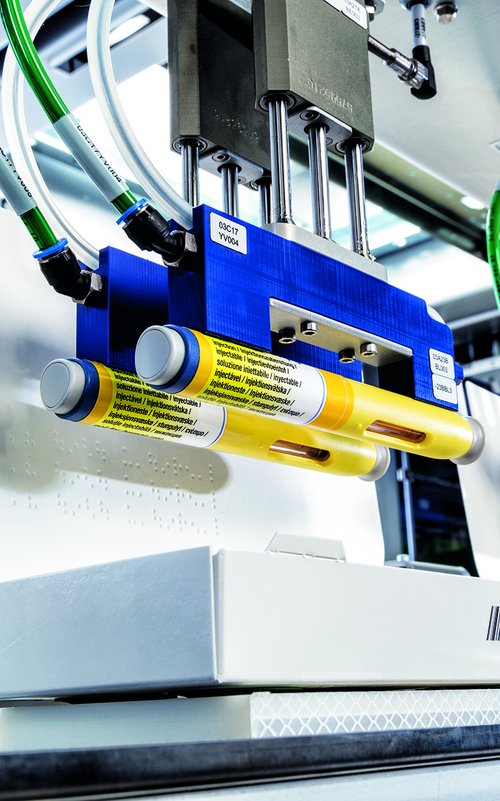

The star wheels are precisely calibrated to meet the high demands of the production process while ensuring maximum product protection. They also offer outstanding flexibility: as interchangeable format parts, they can be adapted to any syringe type. Currently, the system handles five different formats: 1 mL long syringes with 16 mm needles and Soft Cap, Tip Cap, or Hard Cap, as well as 1 mL standard syringes with Soft Cap or Hard Cap. This flexibility allows the manufacturer to respond quickly to future market demands and to prepare in advance for upcoming flu seasons.

"Since we already operate several packaging machines from Schubert, we know and value the company as a reliable partner."

Responsible Project Manager

of the Pharmaceutical Manufacturer

Gentle Handling of 400 Syringes per Minute

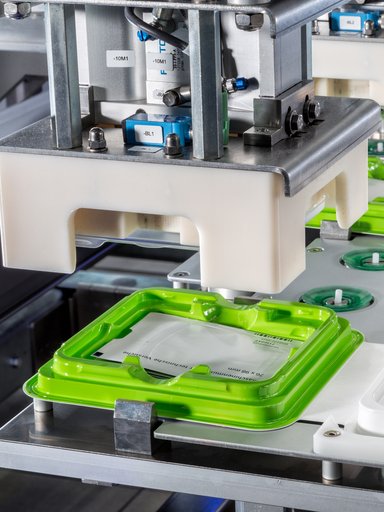

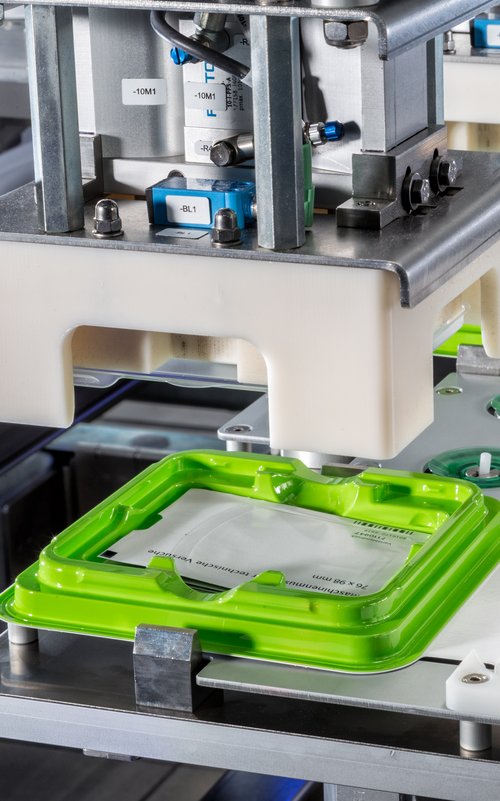

The syringes arriving from the upstream assembly and labeling line are separated into a horizontal lying position with defined spacing using two intermeshing star wheels, which feed the products horizontally into a transfer chain. The first, horizontally positioned star wheel takes the accumulated glass syringes from the feeder and transfers them at defined intervals to the second, angled star wheel, which continues to feed them. This ensures that the syringes reach the transfer chain carriers directly without time-consuming intermediate steps.

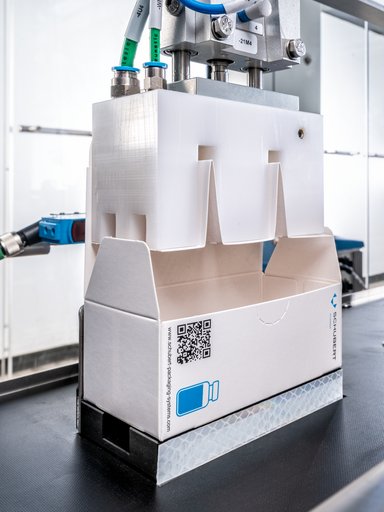

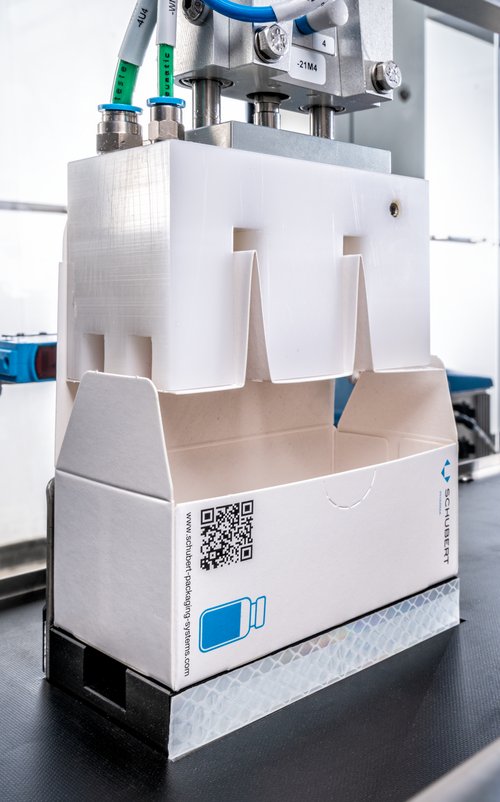

A robot picks up 20 syringes at a time from the chain and places them on a grouping table with four rotating cassettes. Five syringes are grouped in each cassette. The cassettes are then rotated 90 degrees so that a second robot can place them into the prepared trays. In the next step, another five syringes are placed on the grouping table; this time, the cassettes are rotated in the opposite direction. This allows the second robot to position the syringes in the trays opposite to the already placed ones without performing a time-consuming rotation itself.

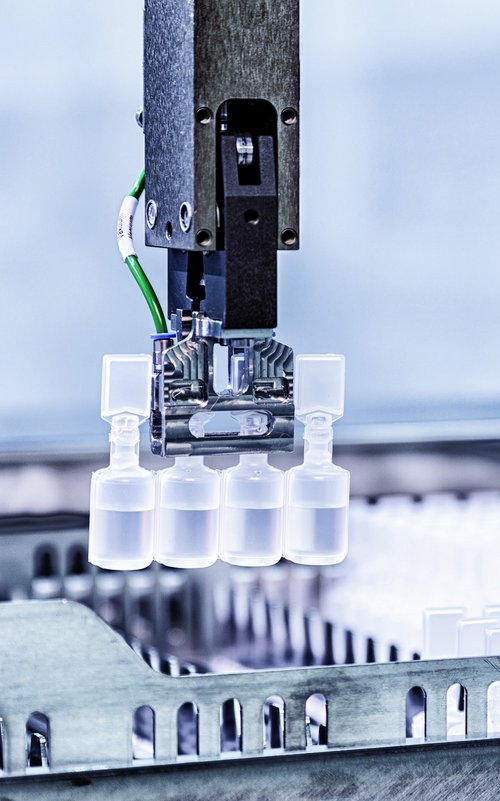

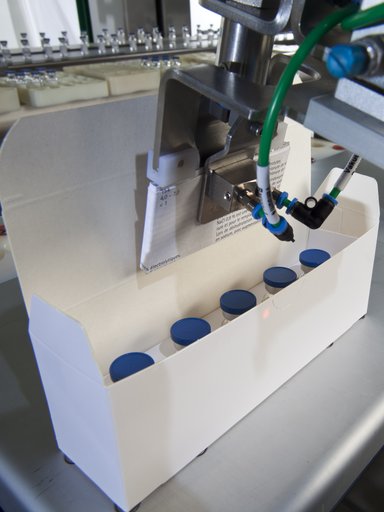

Optical Inspection Ensures Quality

Each set of four trays, containing a total of 40 correctly aligned syringes, is transported via a conveyor to a Schubert camera system. This system checks the correct length, fill level, and orientation of the syringes, and also verifies the presence of the plunger rod, label, and protective cap. Trays containing defective syringes are automatically rejected. Only fully intact syringes in correctly filled trays are subsequently processed and packaged by a Schubert cartoner.