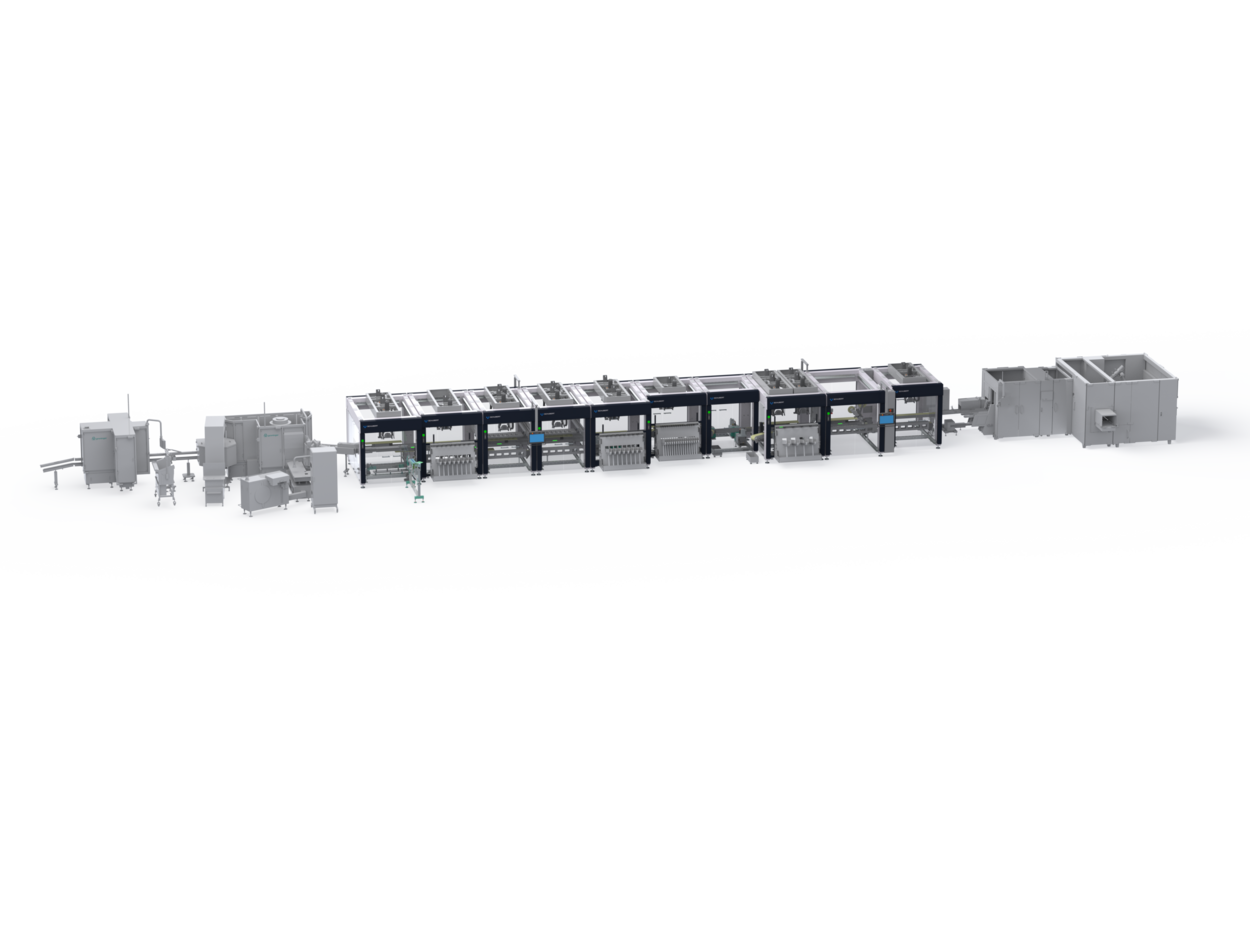

Turnkey Process Solution

We deliver turnkey solutions – from product infeed through primary and secondary packaging to palletizing and integration into your production line.

Special features of

Turnkey process

- Procurement from subcontractors for the realization of a complete line

- Stand-alone machines as well as integrations, e.g. of laser printers or cameras into a complete line

- Project management

- Full line FAT (Factory Acceptance Test)

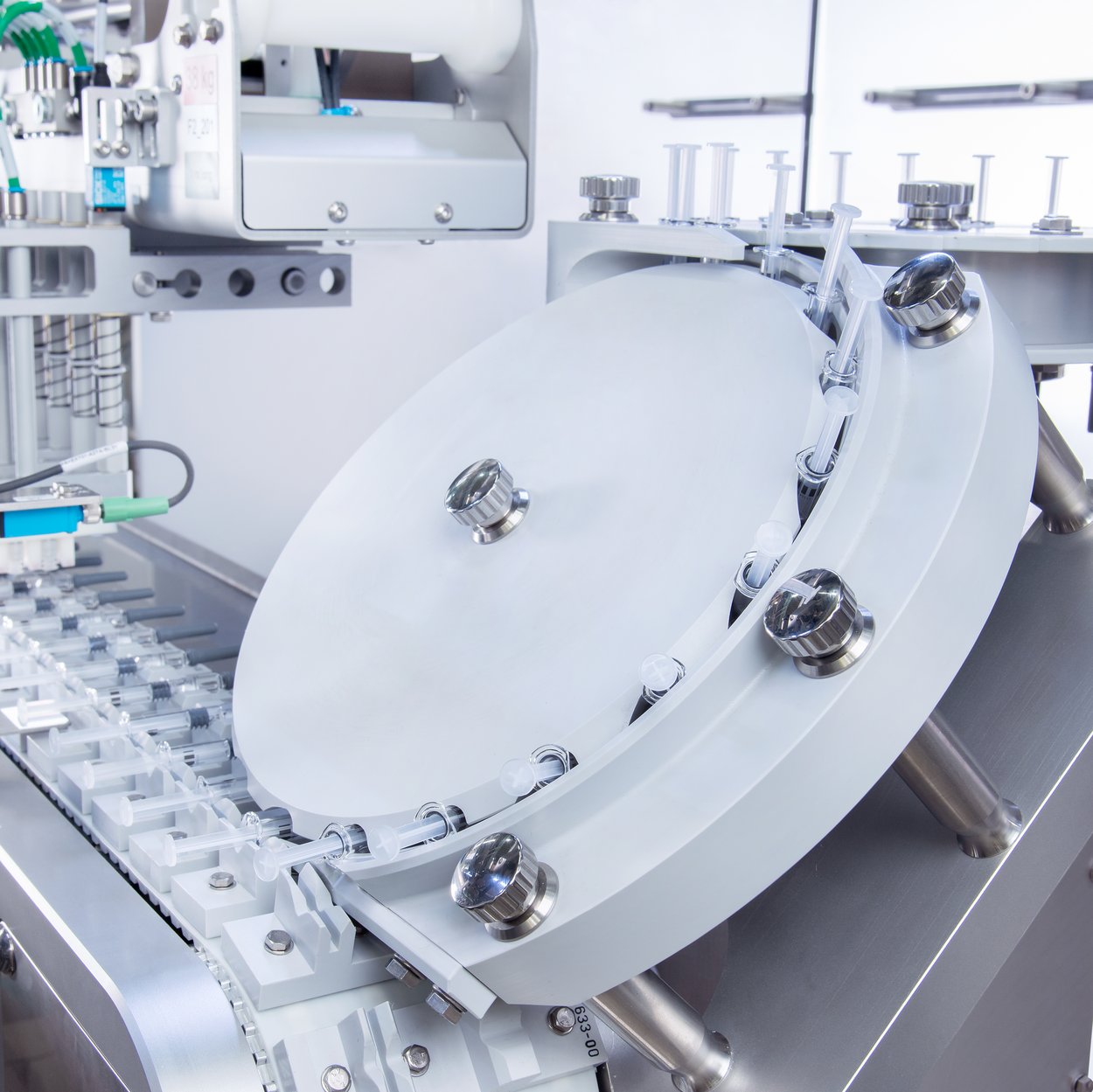

1. Assembly + Labeling: Syringes (groninger)

1. Assembly + Labeling: Syringes (groninger)

2. Cartoner (Schubert)

2. Cartoner (Schubert)

3. Casepacker + Palletizer (Pester)

3. Casepacker + Palletizer (Pester)

Process steps at a glance

Our machines are modular in design and cover all key functions of pharmaceutical packaging – from product handling to palletizing. Here you get a structured overview of the individual steps and how they interact within your machine.

1. Assembly + Labeling: Syringes (groninger)

1. Assembly + Labeling: Syringes (groninger)

The fully assembled and labeled syringes are automatically fed from groninger into the Schubert cartoner.

groninger ensures the integrity of pharmaceutical packaging and the plunger stopper during the plunger rod insertion process with a patented system, where all parameters can be set and saved in the recipe management. They also guarantee extremely precise and gentle labeling of pharmaceutical primary packaging, with only error-free labels applied.

2. Manual infeed: Syringes

2. Manual infeed: Syringes

Alternatively, manual infeed of the syringes at the end of the batch is also possible. In this case, the syringes are loaded by hand directly into the Schubert cartoner.

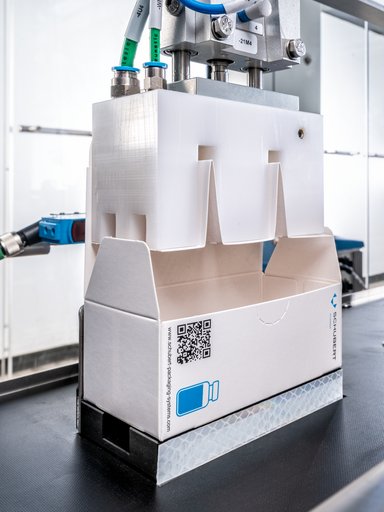

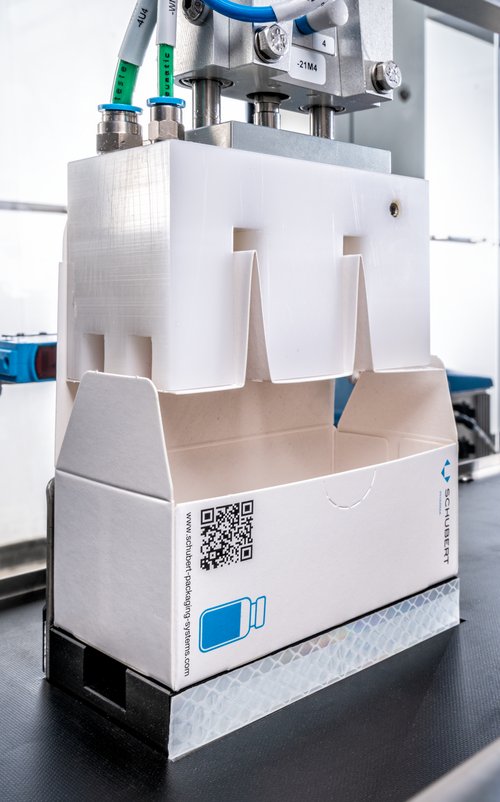

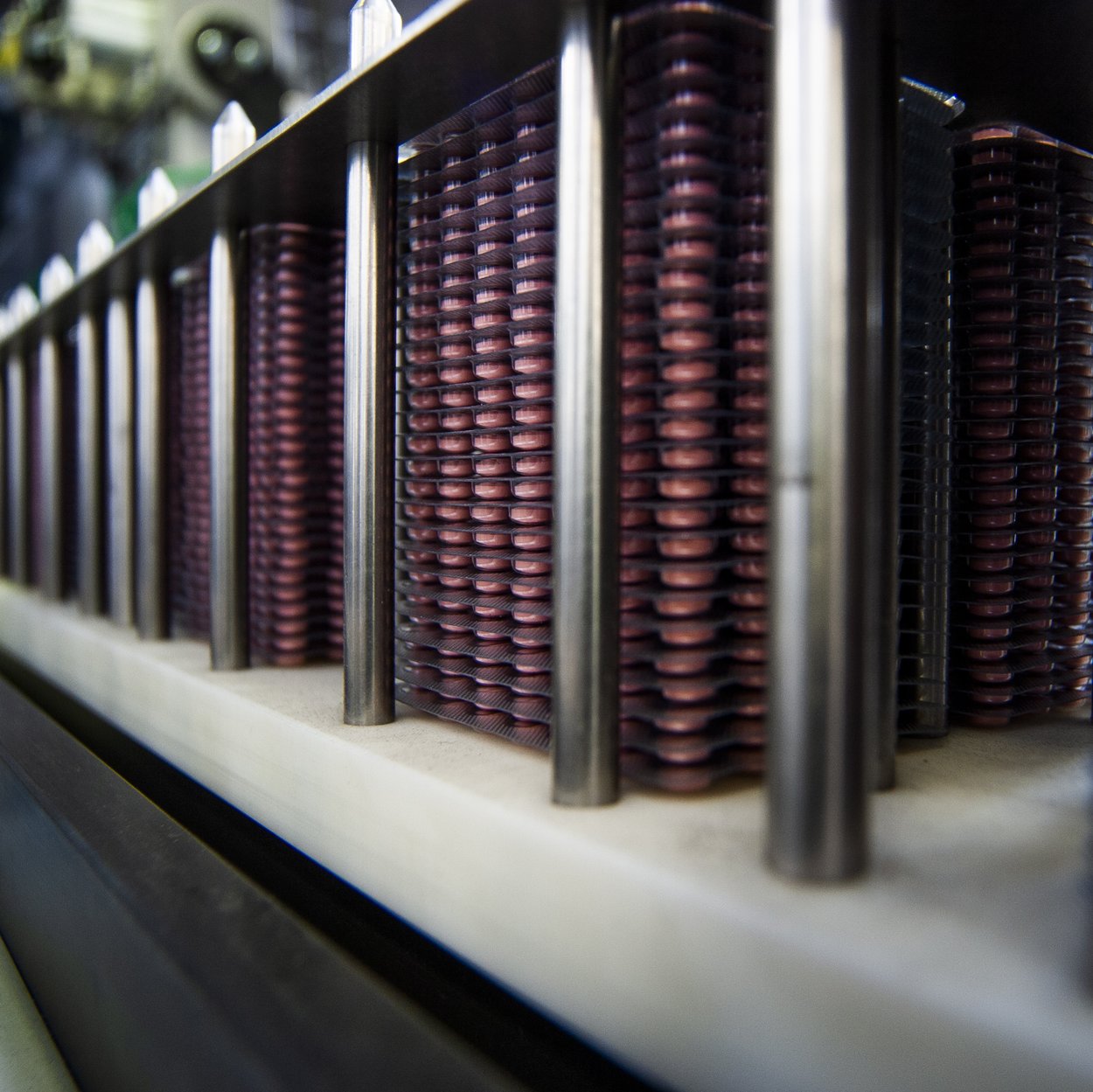

3. Cartoner (Schubert)

3. Cartoner (Schubert)

Depending on the format, the Schubert cartoner packs the syringes into either single or 10-pack cartons. For both formats, the folding carton is first erected and a partition inserted. The syringe(s) are then placed inside, followed by the package insert and the closing of the carton.

4. Serialization (Domino / Antares)

4. Serialization (Domino / Antares)

A Domino laser printer applies a Data Matrix code to the cartons to ensure serialization in the pharmaceutical sector.

5. Labeler

5. Labeler

Finally, a label is applied to the cartons.

6. Casepacker (Pester)

6. Casepacker (Pester)

The case packer takes over the pre-grouped cartons from the cartoner. An RSC carton is erected, the cartons are inserted layer by layer, and the carton is then securely closed.

7. Palletizer (Pester)

7. Palletizer (Pester)

The palletizer stacks the RSC cartons layer by layer onto pallets.

Design and implementation from a single source Turnkey Solutions

We design and implement customized packaging solutions across all project phases.

With a holistic view of your packaging processes, we develop highly reliable systems that are perfectly tailored to your product and its requirements. Our solutions consist of optimally combined components and machines that ensure maximum efficiency and availability.

Based on Schubert technology – and beyond – we offer turnkey packaging systems precisely tailored to your needs. Through interdisciplinary approaches and our extensive experience across different industries, we create solutions that are both cost-efficient and high-performing.

We also integrate additional components, which we source from specialized manufacturers as needed – such as labeling machines, checkweighers or track-and-trace systems – and seamlessly incorporate them into your machine solution. This way, you receive a complete, fully validated turnkey solution from a single source.

Procurement / assembly technology of third-party equipment

- Labeling machine

- Assembly technology

- Infeed

Labeling

- Corner labeling

- Application of a tamper-evident seal

- Device labeling

Buffer / Storage

- Tray buffer loading

Product infeed

- Syringe infeed and orientation

- Turntable infeed for vials

- Centrifugal feeder for syringes

- Friction feeder

Singulation

- Friction feeder for product counting

- Singulation of bulk products

- Separation into individual products

Vision System

- Reading and verification of batch data on transparent labels

- Precise picking from the box using the Schubert 3D camera

- Height profile of the products inside the box

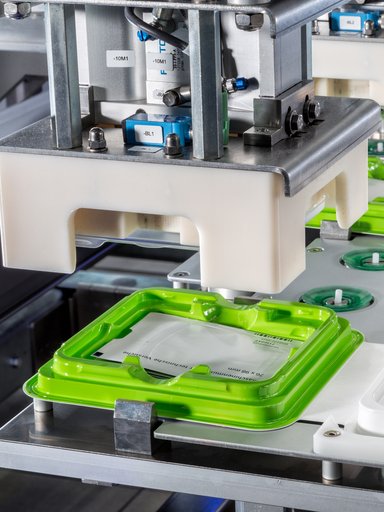

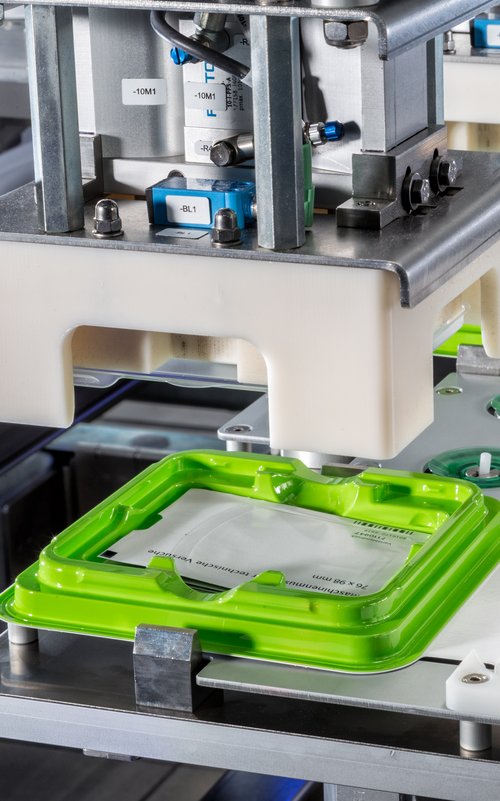

Sealing

- Ultrasonic sealing of cartons

- Thermal sealing of trays with aluminum-laminated film

- Blister sealing with a carton backing

Questions about our turnkey machines? Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com