#SuccessStory #Ampoules #CombinationKits #Vials Fully Integrated Pharmaceutical Packaging Machine as a Turnkey Solution

- Reliable packaging process from product feeding to palletizing

- Maximum flexibility thanks to a wide range of formats and quick changeovers

- Outstanding process quality ensured by Schubert’s pharmaceutical expertise

420

Products per minute

17

Formate

Requirement

Fully integrated line for pharmaceutical manufacturer Lundbeck:

To modernize the packaging of its medicines for neurological disorders, the Danish pharmaceutical company Lundbeck was looking for a new packaging system for ampoules and vials. In the tendering process, Schubert-Pharma – the Schubert Packaging Systems division specialized in the pharmaceutical industry – won the contract with a fully integrated turnkey solution.

Since the new pharmaceutical packaging machine was intended to replace an existing line, all products were already established on the market. This meant that packaging formats, including folding cartons and partitions, were already machine-compatible and did not need to be redeveloped. As a result, the tendering process through to the contract award to Schubert Packaging Systems was shortened to just four months.

One of Lundbeck’s key requirements for the new pharmaceutical packaging machine was to operate with minimal buffering ahead of the packaging process. This meant that only a very small number of products could be in transit between the upstream process and packaging. Conventional feeding technology for pharmaceutical products was therefore not a viable option.

Solution

To ensure the packaging process was set up as efficiently and securely as possible, Schubert-Pharma delivered a fully integrated line. All components of the pharmaceutical packaging machine were sourced directly by Schubert and implemented as a turnkey solution. The system now includes a Schubert cartoner, a B+S labeller, and a Pester bundler, case packer and palletizer. Precise, piece-accurate feeding of ampoules and pipettes through to the carton loading stage was achieved by Schubert-Pharma using a compact buffering system combined with the Beckhoff XTS transport system.

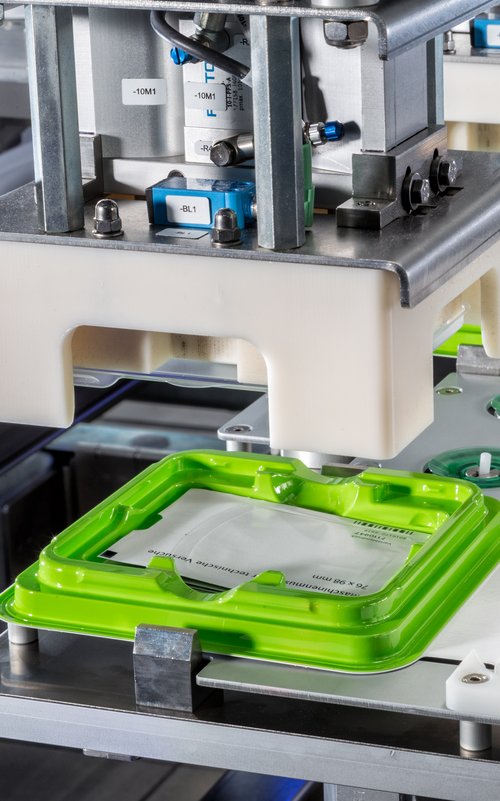

Thanks to the flexible design of the transport system, the supporting columns at Lundbeck’s production site were no longer an obstacle. To integrate the entire process – product labelling, cartoning, banding, case packing and palletizing – within one cohesive solution, the pharmaceutical packaging machine was designed in a U-shape layout. For erecting the various inner partitions, Schubert also developed a universal erecting process that is format-independent and therefore eliminates additional time during format changeovers.

“Thanks to the high flexibility of the packaging line, pharmaceutical manufacturer Lundbeck is now able to gain a competitive edge in the market.”

Karin Kleinbach, Sales Director Pharma

Schubert Packaging Systems GmbH

Flexible and Reliable Packaging Solution in a Single Line

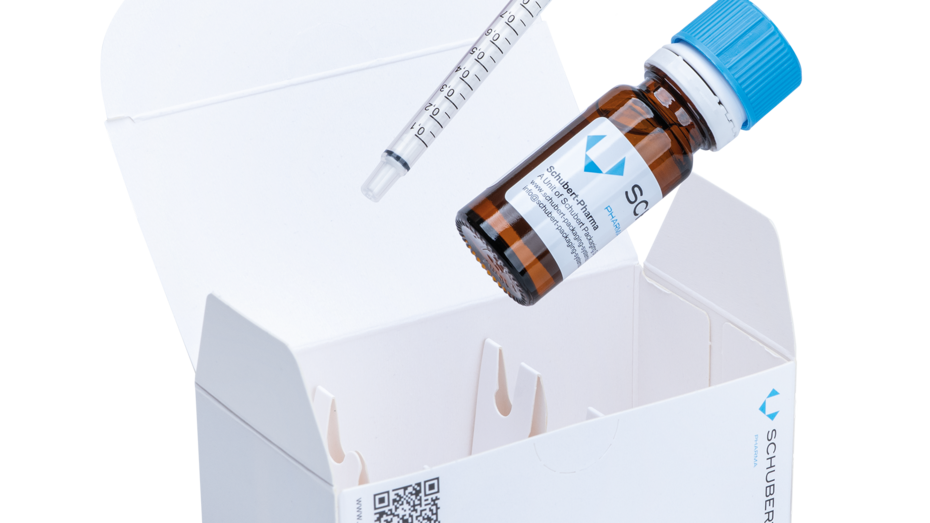

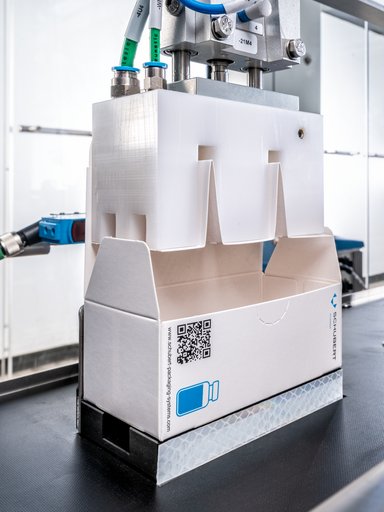

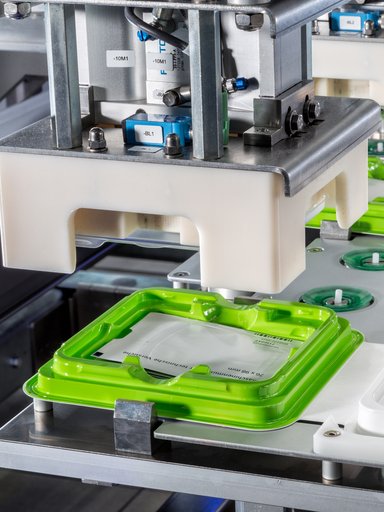

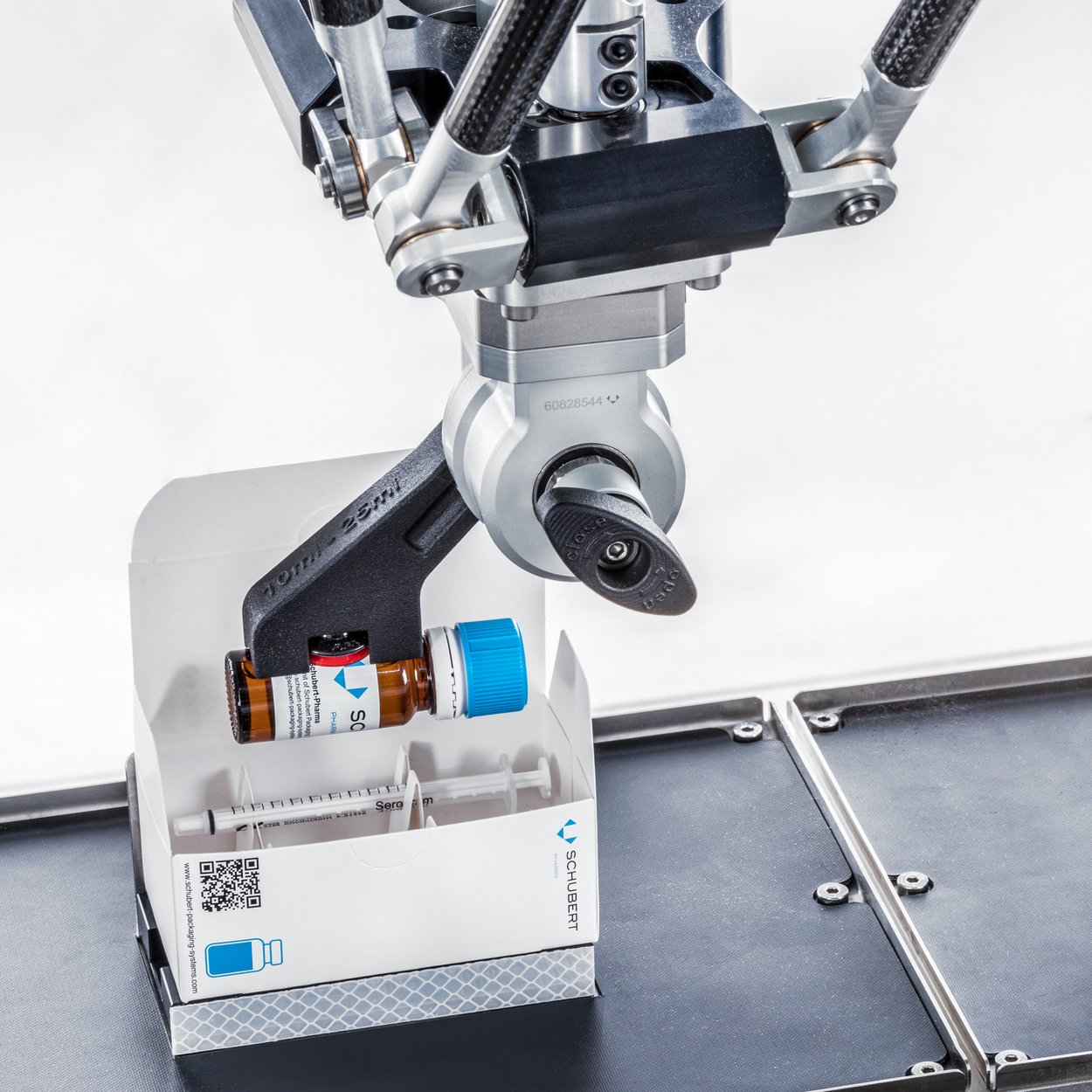

The pharmaceutical packaging line is designed to pack ampoules in two different sizes into cartons containing one, two, five, or ten pieces. In addition, vials – some supplied with pipettes – are packed individually into cartons in four different sizes. To ensure maximum protection, dividers or internal partitions are used for all formats to prevent damage to the glass containers. Each carton is also supplied with a leaflet or booklet and is subsequently labeled.

The entire process within the packaging line – from erecting the cartons and dividers, to loading the pharmaceutical products and leaflets, through to closing and labeling – is carried out using Schubert’s Transmodul transport robot. This ensures a safe, closed packaging workflow. Leveraging its extensive pharmaceutical expertise and advanced robotic technology, Schubert guarantees that all product and packaging tolerances defined in the specifications are consistently met.

Piece-Precise Feeding with Beckhoff System

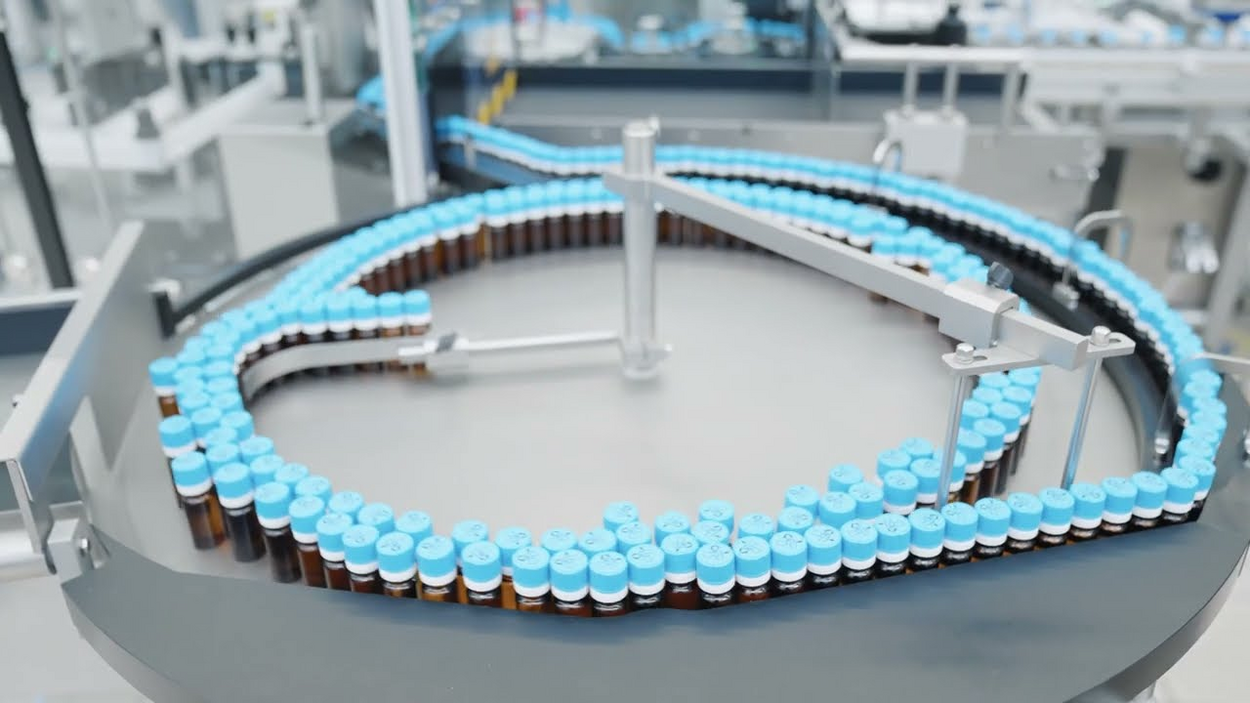

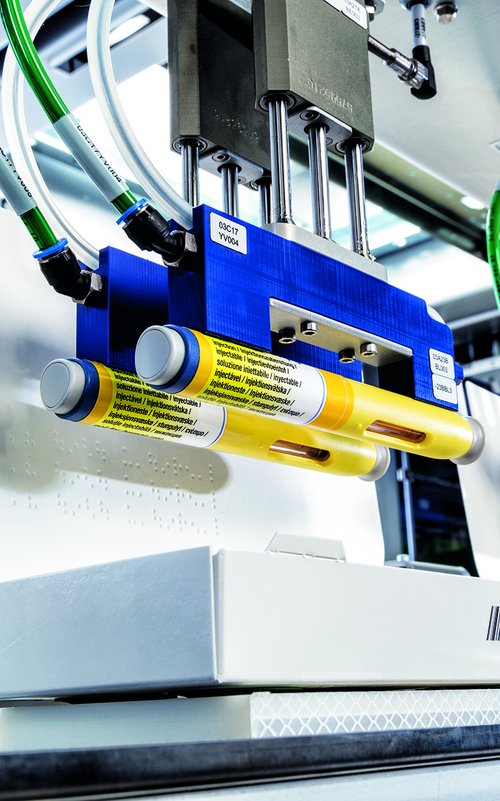

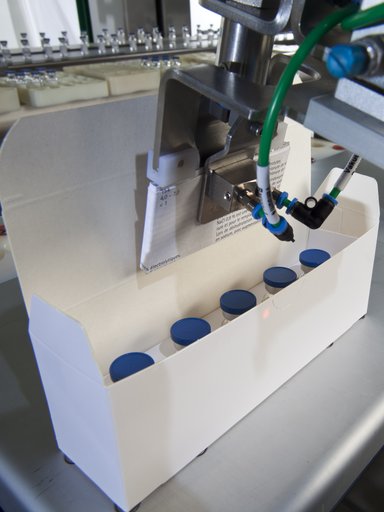

A key feature of the pharmaceutical packaging line is the feeding of ampoules from the labeler and pipettes from the sorting bowl. The XTS linear transport system from Beckhoff delivers products quickly and with piece accuracy from the upstream equipment directly to the cartoner’s loading area. Even short buffering is possible thanks to this highly reliable feeding process.

On the rail-based system, 30 so-called movers – small, independent transport modules – carry format-specific tooling for ampoules and pipettes. After automatic singulation, five products are placed into each mover.

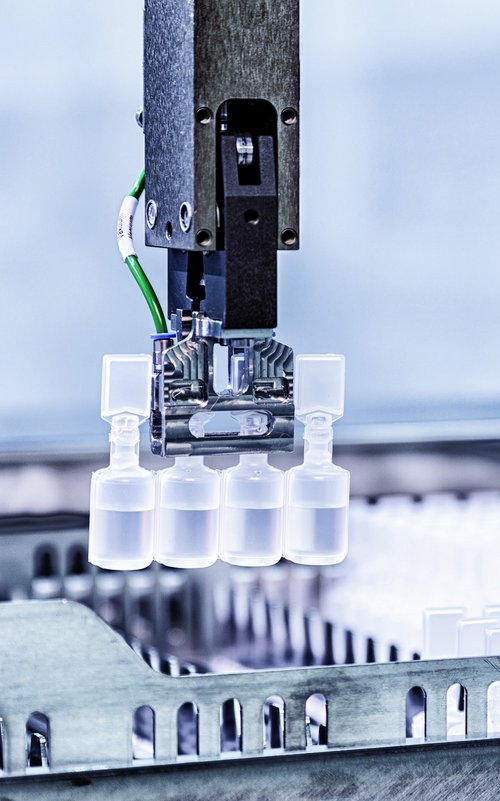

Eight movers are then grouped together at the Schubert cartoner’s loading robot. With its specialized tooling, the robot can pick up 40 ampoules or pipettes at once and pre-group them into sets of ten. From these pre-groups, another robot takes the required number of products for the cartons waiting in parallel on the Transmodul.

The vials, already labeled, are loaded individually into their cartons. After inserting the leaflets, the cartons are closed and labeled before passing through a banderoler, case packer, and finally a palletizer.