#SuccessStory #BFS #EyeDrops Packing BFS Products in plastic trays or folding cartons

- Project management including all preparations and related services

- Integration of all sub-functions into a single line: 7 cameras, 12 scanners, 1 printer, and 1 checkweigher

- Custom line management system: format changes can be performed centrally at the push of a button

- GMP-compliant validation

- Highly flexible system

- Various inspection systems in use: cameras and checkweigher

- Fast format changes

500

Products per minute

10

integrated sub-functions

Requirement

Packaging line for two different products:

The U.S.-based pharmaceutical company Allergan presented Schubert-Pharma with an unusual challenge.

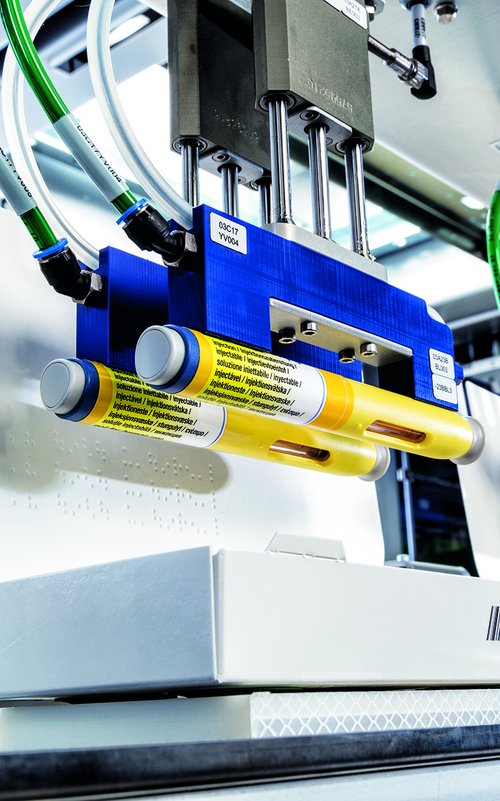

One BFS Product containing light-sensitive ophthalmic solution had to be hermetically sealed in a plastic tray, while a second vial product was to be packed in a folding carton for later retail presentation. The challenge: both products needed to be handled on the same packaging line.

Allergan identified two key bottlenecks in secondary packaging. First, it was clear that the previously used, partially semi-automatic lines would reach their capacity limits due to increasing demand. Second, there was no possibility to quickly switch between different packaging formats.

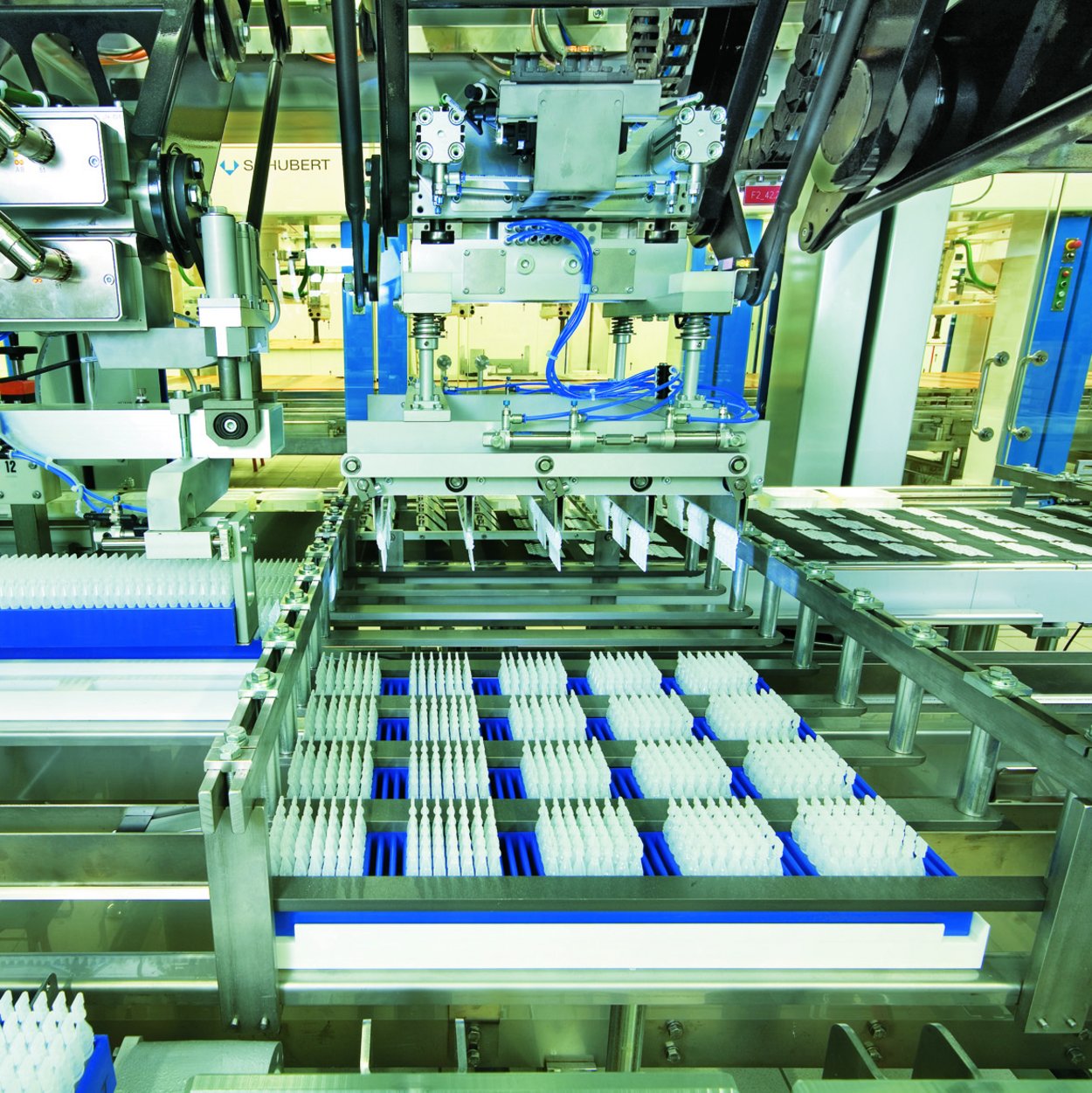

The vial product packed in folding cartons is an over-the-counter product. To offer consumers a wide selection, seven different carton sizes are used, containing 20 to 100 single-dose units.

The prescription-only product is supplied in packs of 30 units. Because these eye drops are light-sensitive, they are packed in hermetically sealed plastic containers. All products in sealed containers require a prescription.

Solution

Schubert-Pharma project planning and implementation:

After an intensive project planning phase, the project engineers at Schubert-Pharma presented a coherent concept for the packaging line and were awarded the contract to realize this extensive system. Ultimately, ten partner companies contributed to the completion of the packaging line.

The contract also included a comprehensive risk-based validation package as well as the integration of all system components in Crailsheim. Following extensive validation runs and acceptance tests, and after training the customer’s personnel, the line was delivered to the client to go into production within a few weeks.

To ensure seamless changeovers between different formats, a line management system was programmed to monitor and centrally control all machines, camera systems, scanners, and printers.

With this software solution, format changeovers can be executed at the push of a button. The system also automatically defines the variable data to be printed, and all cameras receive the same information for data verification. Mechanical adjustments, such as loading magazines with different materials or changing tools, take approximately 45 minutes.

“Our goal was to gain a competitive edge in packaging technology through German cutting-edge engineering. Schubert-Pharma made this possible. They work very efficiently, which significantly reduced our effort in managing this highly complex project.”

Ron Lentsch, Vice President NA Operations

Allergan

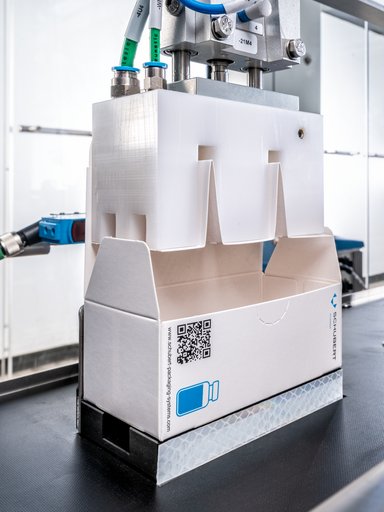

Loading of Folding Cartons or Plastic Trays

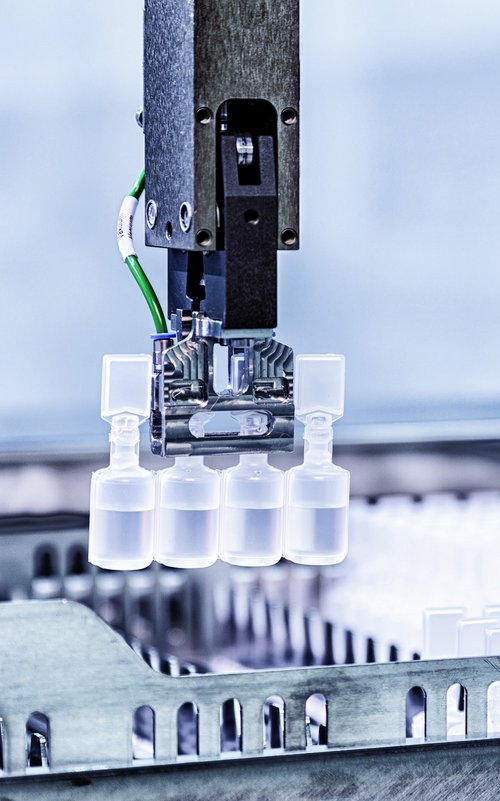

The BFS Products are fed offline on product carriers. Sets of five single-dose plastic containers (4 ml each) are pre-attached and ready to be separated. An F2 robot picks the individual products and places them onto a product conveyor in four lanes. Four camera systems, each paired with sensors, check that every vial bears the correct 2-D matrix code and that it is readable. As with all subsequent inspection points, units identified as defective are automatically rejected.

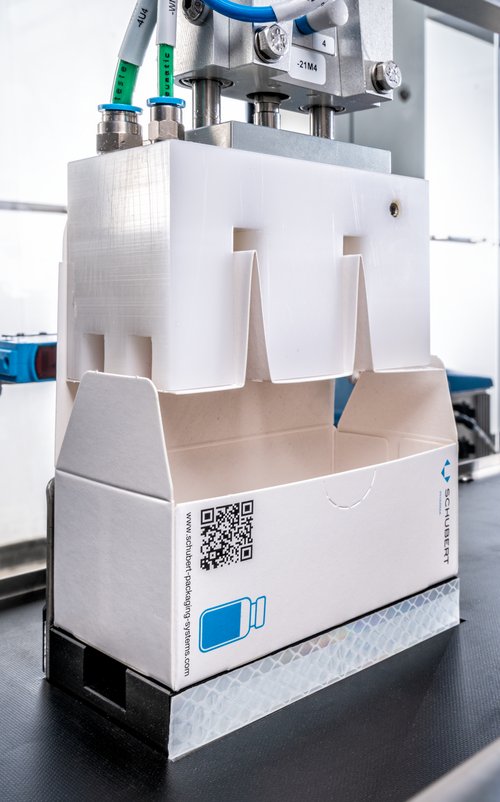

In the following picking line, the product is sorted into plastic trays or folding cartons according to the selected format. The respective packaging material is sorted on carriers moving in the opposite direction on a conveyor. Before this, the carton blanks or plastic trays are automatically retrieved from a magazine. The carton blanks are erected, glued with hot melt adhesive, and then placed into the carriers.

The subsequent process steps vary depending on the type of packaging being processed.

Shelf-Ready Packaging for Folding Cartons

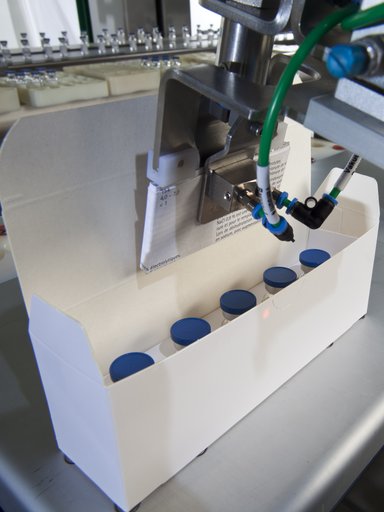

In the next TLM module, an F2 robot equips the folding cartons with a package insert and closes them. At the machine outlet, a laser system applies a code to each carton. The cartons are then conveyed by another TLM machine - whose functions are only required for the plastic trays - up to an inspection station where a camera system verifies the printed code. In the subsequent shrink-packing module with a heating tunnel, each carton is additionally wrapped in film. An integrated checkweigher within the conveyor system ensures that the correct weight is achieved.

Another TLM module places the folding cartons into a shelf-ready packaging. Trays are erected from blanks, glued, and filled with 24 to 40 packages depending on the format. Finally, the system conveys the carton to the closing unit and then out of the line for further handling in logistics.

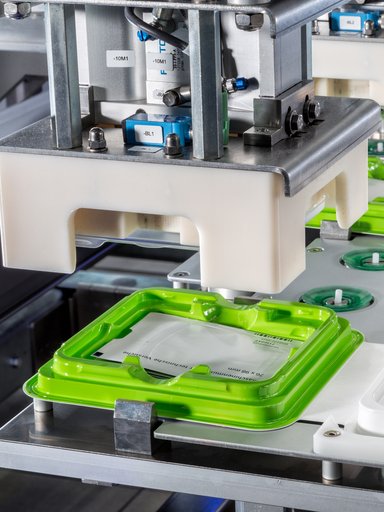

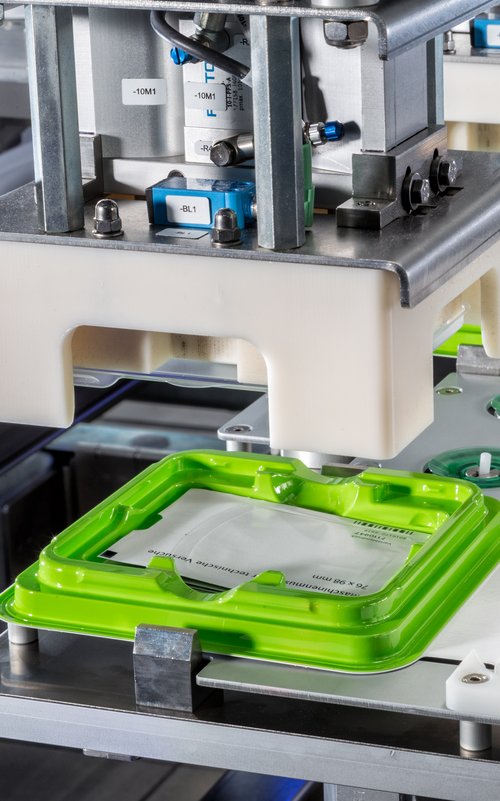

Packaging in plastic trays and outer cartons

For the trays containing the prescription eye drops, the next station after filling is a tray sealing unit. Here, the containers are hermetically sealed with aluminum foil. Immediately at the station’s outfeed, a camera system checks whether the sealing has been carried out properly. In the two following TLM modules, which simply convey the folding boxes through, a package insert is first placed onto the aluminum foil, followed by a plastic lid. Both components are automatically picked from magazines beforehand.

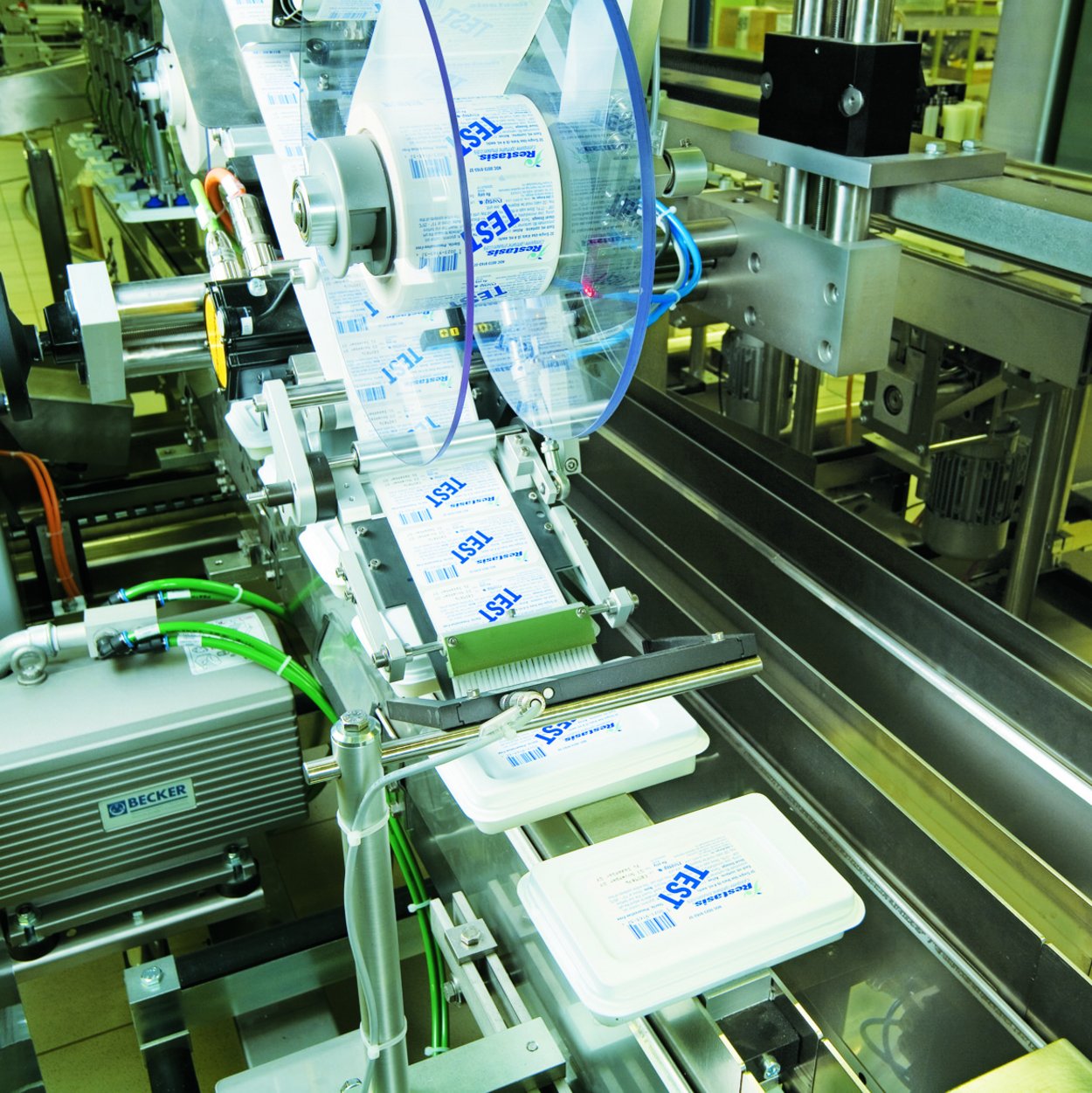

In this section of the line, an integrated device applies and prints a label onto the lid. A camera system verifies the print. At the machine outfeed, another camera system checks the correct positioning of the label and once again verifies the printed information.

Afterwards, the sealed trays, as well as the folding boxes, pass through the shrink wrapper and the checkweigher. The next step can also be used for both packaging types: The containers are packed into shipping cartons within the TLM system. These cartons are erected from blanks and sealed with adhesive tape on the bottom. In the final section of the line, the top of the carton is also sealed with adhesive tape.