#SuccessStory #Ampoules #Vials Plastic Tray from the Roll

- Optimized material usage through integrated thermoforming

- Packaging of vials and ampoules

- Format variety for small packages: e.g., 5 vials/ampoules per blister/carton, up to 10 blisters with 5 products each per carton

- Rapid format changeovers

- Decoupling of the thermoforming machine from the loading and cartoning process

- Future-proof rationalization of packaging possible

400

Millimeter-wide Film Web

5

Vials / Ampoules in one Blister per Carton

Requirement

Faster Format Changes for Ampoule and Vial Packaging

Schubert-Pharma was tasked with developing a more efficient packaging process that would allow the manufacturer to achieve faster format changes and reduce material costs.

The renowned filler for ampoules and vials, Takeda, wanted to thermoform plastic trays directly from the roll. The advantages are clear: lower material costs, reduced logistics effort, and higher efficiency in the packaging process.

Previously, Takeda had to store pre-formed plastic trays in magazines and depalletize them for the packaging process due to cumbersome format changes. This improved handling came at the cost of higher material consumption. Schubert-Pharma was commissioned to reverse this approach and implement a more efficient solution.

Solution

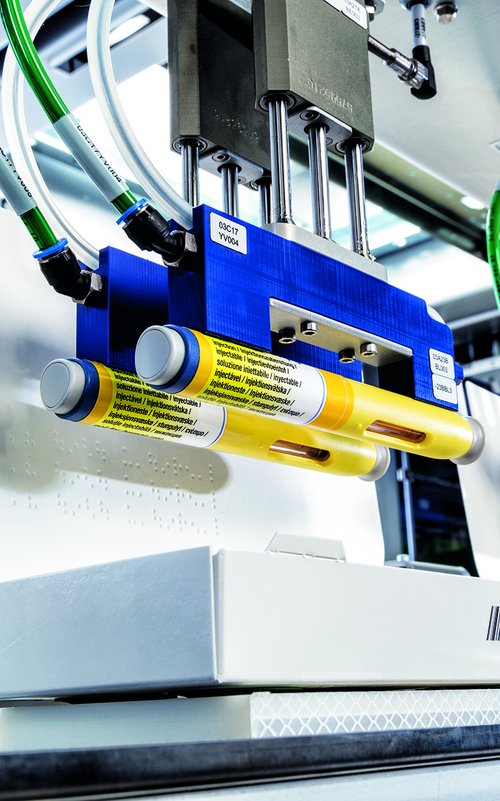

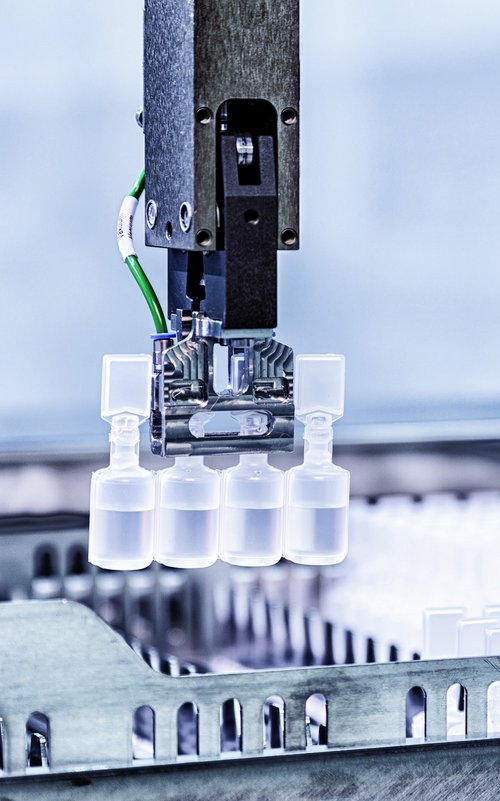

The line designed by Schubert-Pharma for Takeda is distinguished by the decoupling of the thermoforming machine from the loading and cartoning process. The packaging line is capable of handling both vials (standing in trays) and ampoules (lying in clamping trays).

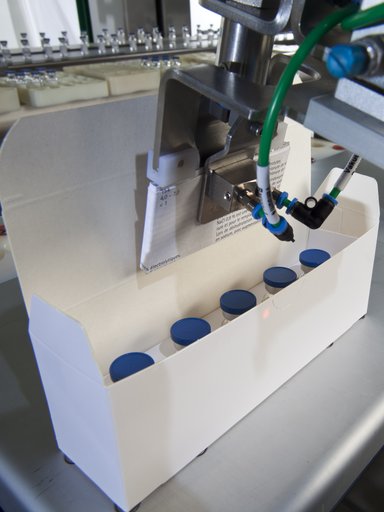

Notably, the system supports a wide range of formats: from small packs—such as five vials or ampoules per blister/carton—to ten blisters with five products each per carton.

With this machine, Schubert-Pharma provided the filler with a system that will continue to support further rationalization and efficiency improvements in packaging in the future.

The line is particularly characterized by the decoupling of the thermoforming machine from the loading and cartoning process.

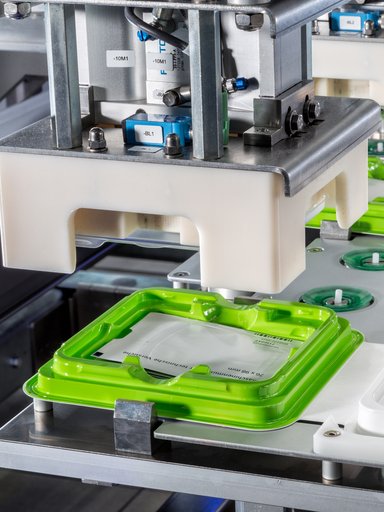

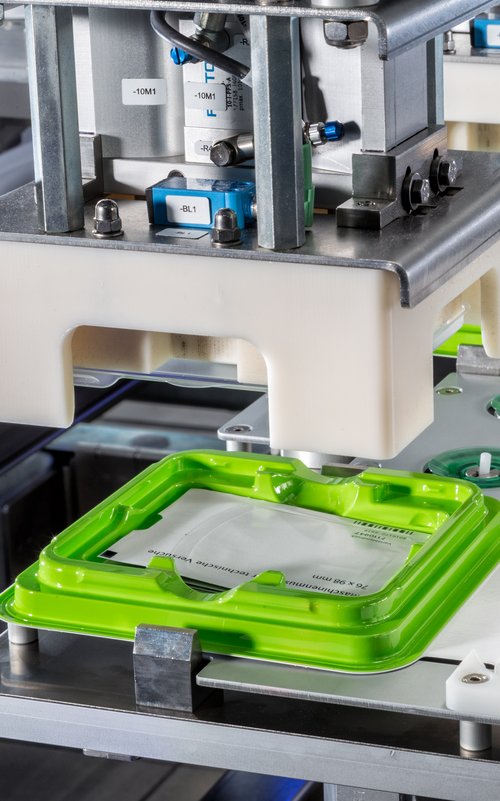

Thermoforming the Blister

In the thermoforming unit, the blisters are formed and punched out. A pre-stretching punch is available for the thermoforming process. The 400-millimeter-wide film web runs continuously at a speed of up to nine meters per minute. Punching is carried out using ultrasound, a method that allows for any punching contour and guarantees cost-effective tools with quick format changes. The thermoforming and punching units automatically adjust to the film speed. The entire machine is programmed via parameter input on the screen.

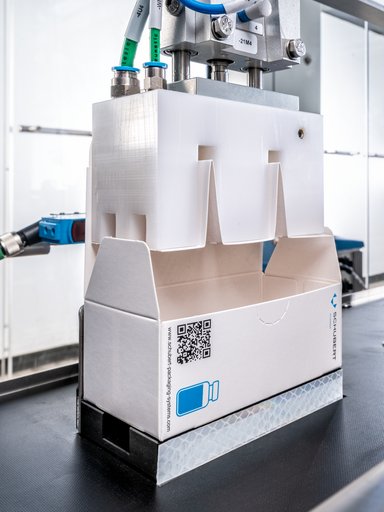

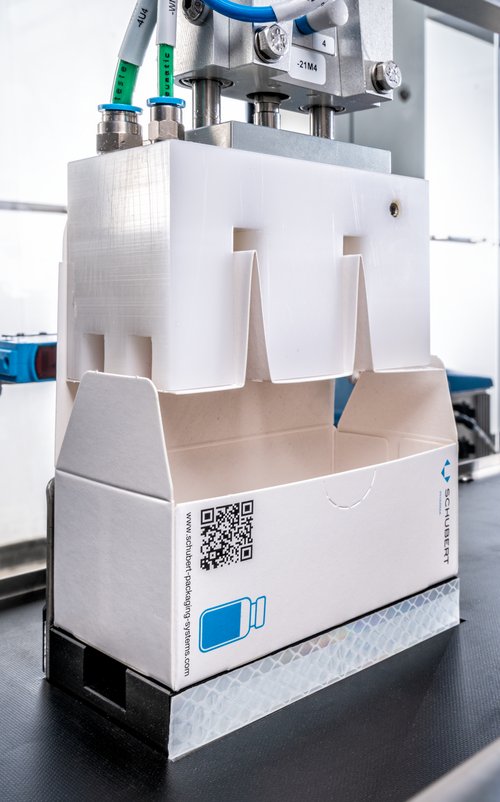

Loading and Cartoning Process

The blisters are then prepared for loading. At the same time, the products (vials or ampoules) are fed into the machine and pre-grouped. The loaded blisters are placed into previously erected top-load cartons and sealed after the addition of the package insert. After the individual cartons are labeled using inkjet printers, they are transferred to the downstream logistics system.