Customized Process Solution

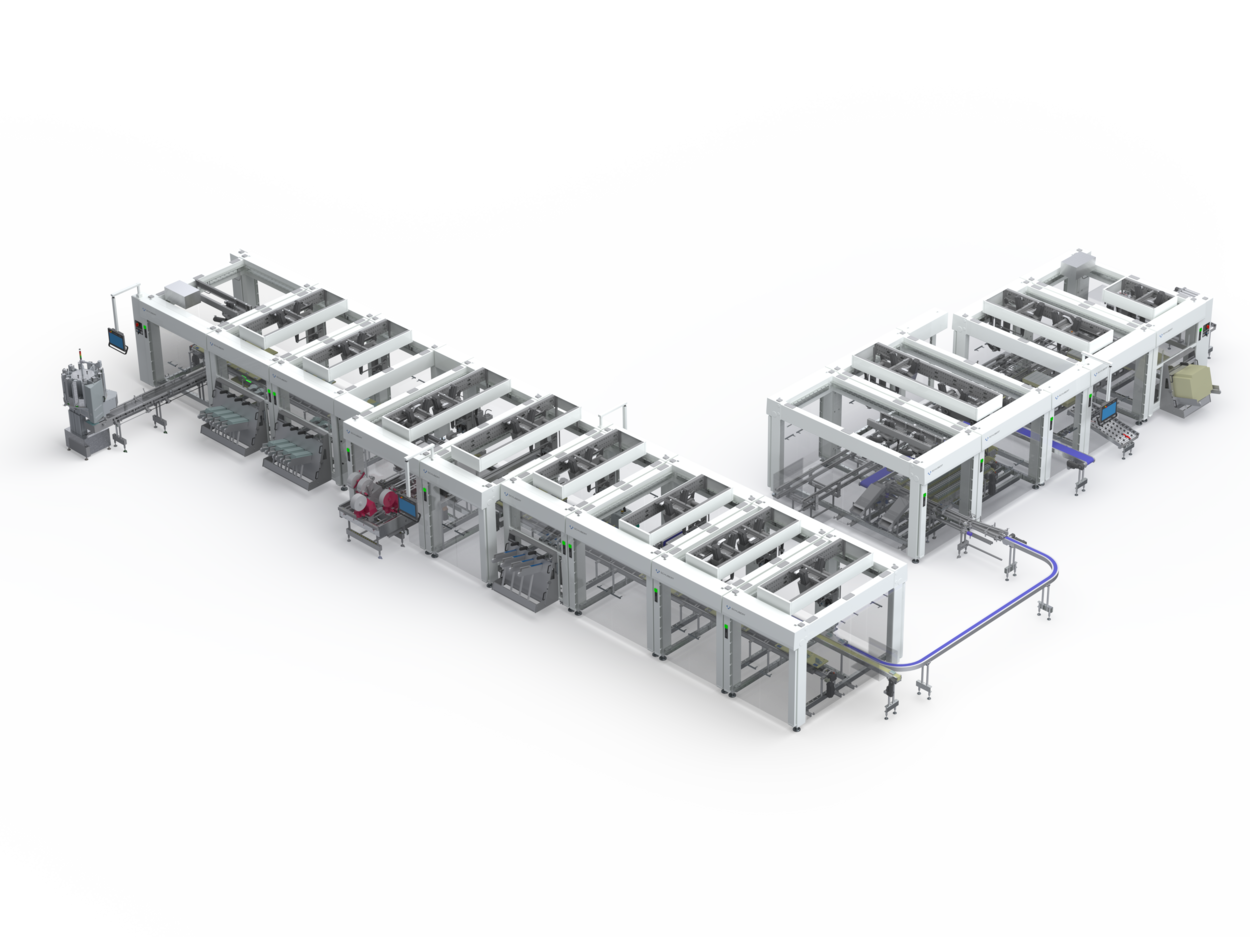

For special requirements, we develop customized systems – modular, flexible and precisely tailored to the product, packaging and process of your application.

Other products already packaged by Schubert-Pharma:

- Health Care (plasters)

- Hospital Care (infusion bags)

- Canisters

- IOL (intraocular lenses)

Process steps at a glance

Our machines are modular in design and cover all essential functions of pharmaceutical packaging – from product handling to palletizing. Here you get a structured insight into the individual steps and how they interact within your machine.

Cartoner

Cartoner

Infeed: Product (Revolver magazine by Co. Rontech)

Different products are fed into the cartoner’s transport system (pusher chain) in a non-defined sequence.

DMC inspection (Co. Cognex)

The DMC on the product is read and provides all necessary information to the customer’s system. From there, all production-relevant data (print data, product information, parameters for camera verification) is extracted and distributed via HEITEC to all systems on the line (Domino laser, Domino printer, Cognex camera systems, Balluff RFID read/write heads), ensuring availability at the required time. The corresponding Track & Trace is managed between Schubert and Heitec. This information is not only distributed to the aforementioned devices but also to the Schubert control system, which then retrieves the appropriate blanks from the magazines and initiates the corresponding process steps.

Carton erecting

The flat cartons are stored in an eight-lane magazine. The TLM-F3 robot takes a blank from the magazine and presents it to the TLM-F2 robot. The blanks are then printed with individual data using a laser printer, verified by a camera and either erected or rejected. During erection, the TLM-F2 robot passes the blank over the glue nozzles and presses it through a forming die.

Printing / cutting / folding: Label

In parallel, a label set (from a continuous label roll) consisting of 8 labels is cut in four lanes, printed with product-specific information, verified by a camera, folded, and added to the transport system.

Infeed / processing: Patient ID card

Also in parallel, patient ID cards are processed. These are taken from the four-lane magazine, written via RFID read/write heads by a TLM-F2 robot, verified, and then placed onto a pusher chain. Further product-related information is then marked on them by laser and, after camera inspection, they are fed into the transport system.

Filling: Product, label, patient ID card

All components (approved products) are packed into the erected carton.

Closing: Cartons

The carton is closed by a TLM-F2 robot and placed onto the outfeed conveyor.

Recovery cycle

Incomplete product or packaging units are temporarily stored on the Transmodul instead of being rejected immediately. They pass through the machine again, where missing components are automatically added.

Outfeed: Carton

The closed carton leaves the cartoner via the outfeed conveyor.

Casepacker

Casepacker

Infeed: Cartons

The cartons are fed in single file from the upstream machine (cartoner) into the case packer.

DMC inspection with camera

The DMC on the cartons is read and verified. Based on this information, it is defined which distribution center (1–5) will receive a specified number of products from a batch.

Carton erecting

The flat blanks are stored in a magazine. The TLM-F3 robot picks up a blank from the magazine and presents it to the TLM-F2 robot. The TLM-F2 robot passes the blank over the glue nozzles and presses it through a forming die, erecting the carton.

Printing / inspection (external: Domino inkjet printer, Cognex camera)

The carton is printed with distribution-center-specific information, which is then verified by a camera. If the carton is rejected, it is discharged. If accepted, it is placed on a two-lane vacuum transport system and conveyed to the filling station.

Filling: Carton

Once 19 products have reached the end of a chain, TLM-F2 robots transfer them via an intermediate table into cassettes representing the distribution centers (5 x 19 cartons). These cassettes are fixed on two levels (five cassettes per level) by transport racks. The two-level transport racks function as a buffer system to ensure continuous machine operation without interruption. Once a cassette is completely filled, the respective rack moves into the unloading position.

Outfeed: Carton

The carton leaves the case packer on an outfeed conveyor.

Individual machine solutions for your pharmaceutical production

Not every pharmaceutical application can be implemented efficiently with a standard solution. That’s why at Schubert we develop customized packaging machines that are precisely tailored to your requirements – from the integration of specific formats to special transport and handling needs.

Our modular top-loading systems provide the flexibility needed to implement even complex packaging processes safely, GMP-compliantly and efficiently. Together with you, we develop solutions that fit precisely with your line and product portfolio.

1/Batch processing

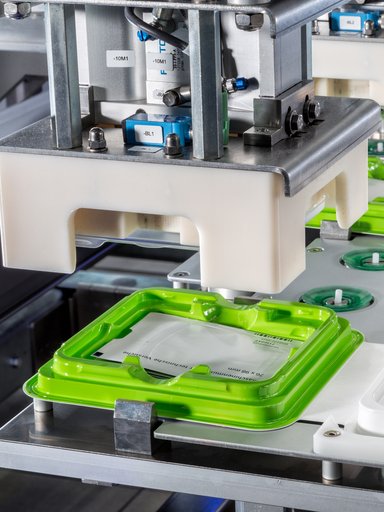

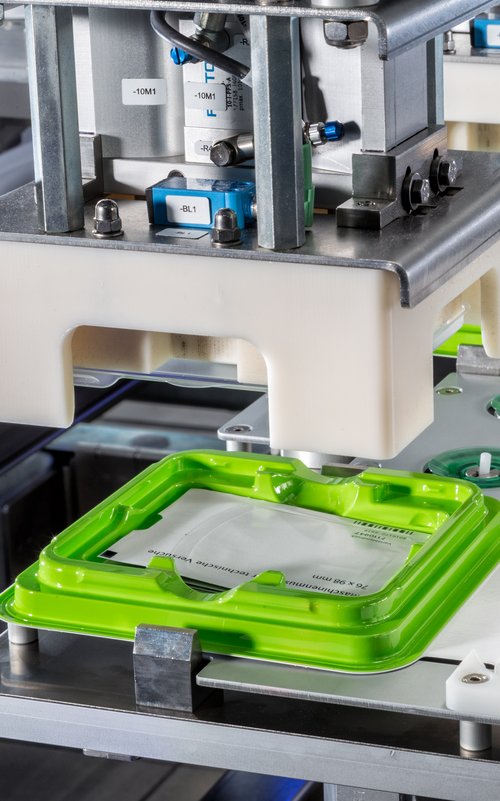

Different product blisters and various batches are fed into the Schubert transport system via a rotary magazine. At the machine infeed, the applied DataMatrix codes (DMC) are automatically checked.

The captured information is transferred to the customer’s control system via the Line Control System developed by HEITEC and from there distributed to all relevant components of the line. This ensures that laser, printing and camera systems as well as RFID read/write heads always have the correct data available.

A central principle here is 1/Batch processing: Each product is clearly assigned to a batch. This guarantees complete traceability, data security and a smooth production flow – even with varying products and batch sizes.

Cutting, printing and folding labels

For efficient and process-reliable marking, labels are processed in parallel with the packaging process. From a continuous label roll, a four-lane label set with a total of eight individual labels is produced.

These labels are first cut, then printed with product-specific information and checked for accuracy and quality using a camera system. After successful verification, the labels are precisely folded before being fed into the main transport system and integrated into the subsequent packaging process.

Top-loading and

side-loading combined

For cartoning, Schubert developed special blanks that can be used in both top-load and side-load applications.

This dual design ensures that the blanks can be processed smoothly not only on Schubert machines but also on side-load machines at other production sites.

In this way, a standardized packaging solution is created that works across sites while providing maximum flexibility in production.

Patient ID cards with RFID technology

The patient ID card serves as a central data carrier in the pharmaceutical packaging process. The integrated RFID chip securely stores product-specific information – such as batch data or patient-specific details – and enables contactless reading.

In addition, laser marking on the patient ID card allows permanent labeling with further relevant data. This reliably links production and patient data, which is essential both for traceability and for patient safety.

Distribution Center

The distribution center plays a key role in the organization and allocation of pharmaceutical products within the packaging line. Here it is defined which distribution center receives a specific number of products from a batch. In the Schubert solution, this is represented by five parallel product chains, each taking up and transporting cartons.

The special feature: the system is designed for precise tray filling. Up to 19 cartons per chain can be placed in one tray. Specially developed cassettes, arranged on two levels, serve as distribution centers. These cassettes also function as a buffer system, ensuring continuous packaging operations without downtime. Once a cassette is completely filled, it is automatically moved into the unloading position.

Recovery cycle

In Schubert’s packaging process, there are no classic rejections of entire product groups. Instead, the machine uses what is known as the “recovery cycle.” All components classified as good – such as carton blanks, label sets or patient ID cards – remain on the Transmodul. Only the defective or missing component is reproduced and added during a second pass.

The advantage of the recovery cycle: incomplete product or packaging groups are not immediately treated as waste but are passed through the machine again. This significantly reduces material consumption while increasing process reliability. Unlike conventional machines, where a single error leads to the rejection of all components that then need to be manually completed, the correction here takes place fully automatically and efficiently.

Questions about

our Customized Solutions?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com