Combination kits packaging

- Modular configuration for individual kit assemblies

- Precise feeding and positioning of all components

- Integration of inspection, labeling, and leaflet insertion

- GMP- and FDA-compliant line design

- Future-proof machine architecture for new requirements

Special features of

combination products

Combination products bring together multiple components into a single medical application unit. With Schubert packaging systems, even complex processes for combination products can be implemented flexibly and precisely. Inspection, completeness, and traceability are fully integrated into the workflow.

1. Infeed: Clamshell / Package inserts

1. Infeed: Clamshell / Package inserts

Clamshells and package inserts are stored together in a magazine. A TLM-F3 robot picks up one clamshell and one leaflet from the magazine and hands them to the TLM-F2 robot. First, the clamshell is positioned on the Transmodul, then the TLM-F2 robot picks up the leaflet and inserts it into the clamshell. A code reader scans the information on the leaflet and provides all necessary data to the customer’s system. Incorrect package inserts are immediately rejected.

2. Infeed: Plunger

2. Infeed: Plunger

The plungers are fed into the system via a Sortec feeding system.

3. Load: Plunger

3. Load: Plunger

A TLM-F4 robot takes the plungers from the feeding system and inserts them into the clamshells on the Transmodul.

4. Infeed: Mini-spike

4. Infeed: Mini-spike

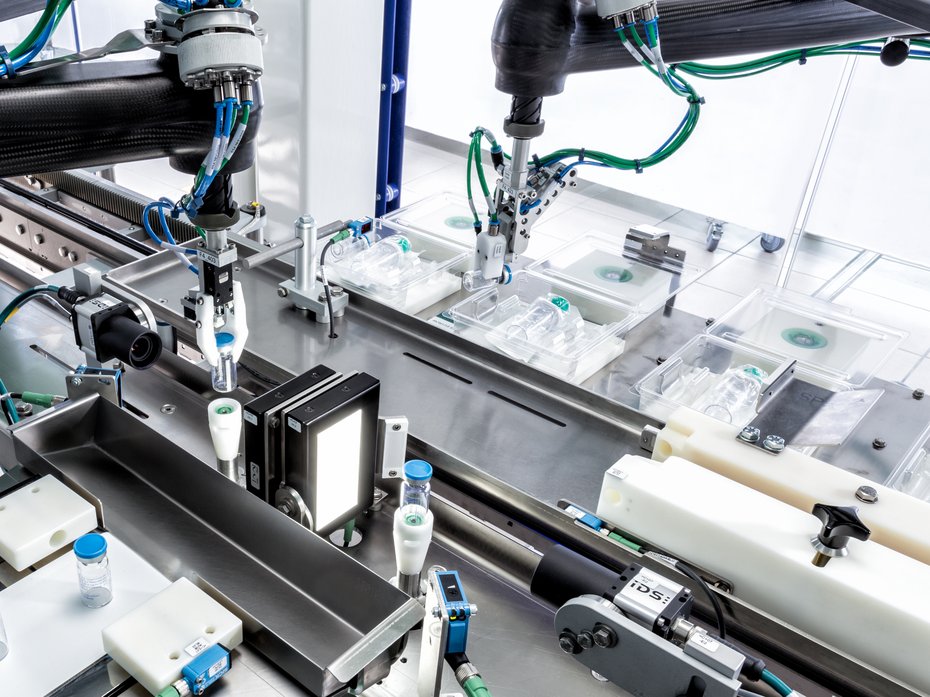

The mini-spikes are fed into the system via a Sortec feeding system. A scanner detects the position and orientation of the products and transmits this information to the TLM-F4 robot controller. A code reader checks the data on the code and, if necessary, immediately rejects incorrect products

5. Load: Mini spike

5. Load: Mini spike

A TLM-F4 robot takes the mini-spikes from the feeding system and inserts them into the clamshells on the Transmodul.

6. Infeed: Vials

6. Infeed: Vials

The vials are fed into the system via a rotary table. A camera reads the variable data on the vial label and immediately rejects incorrect products if necessary.

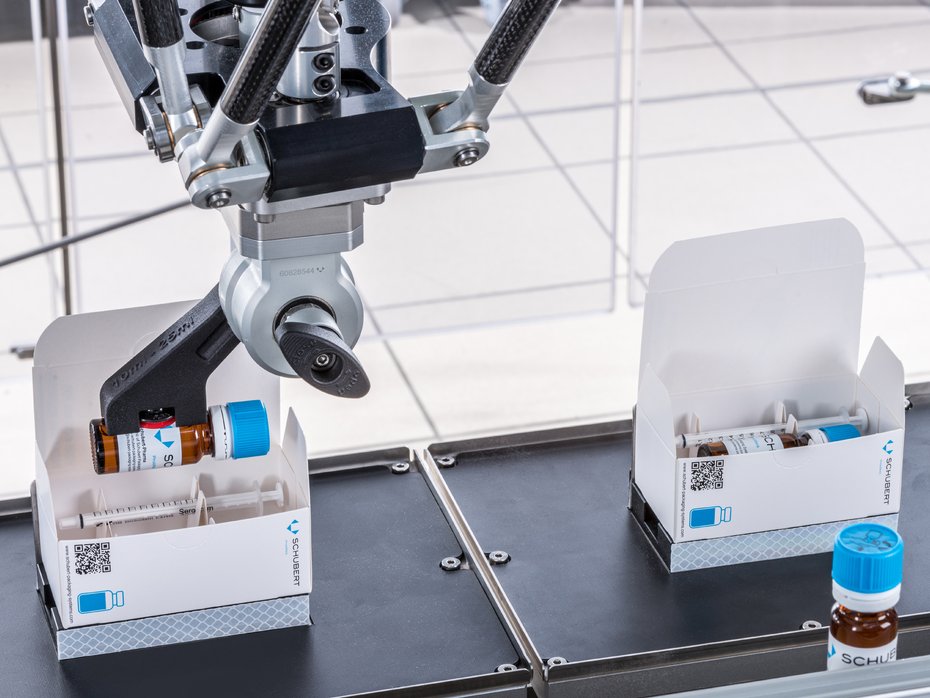

7. Load: Vials

7. Load: Vials

Ein TLM-F4 Roboter übernimmt die Vials vom Drehteller und setzt diese in die Clamshells auf dem Transmodul ein.

8. Infeed: Syringes

8. Infeed: Syringes

The syringes are fed into the system via a Sortec feeding system. A camera reads the variable data on the syringe label and immediately rejects incorrect products if necessary.

9. Load: Syringes

9. Load: Syringes

A TLM-F4 robot takes the syringes and inserts them into the clamshells on the Transmodul.

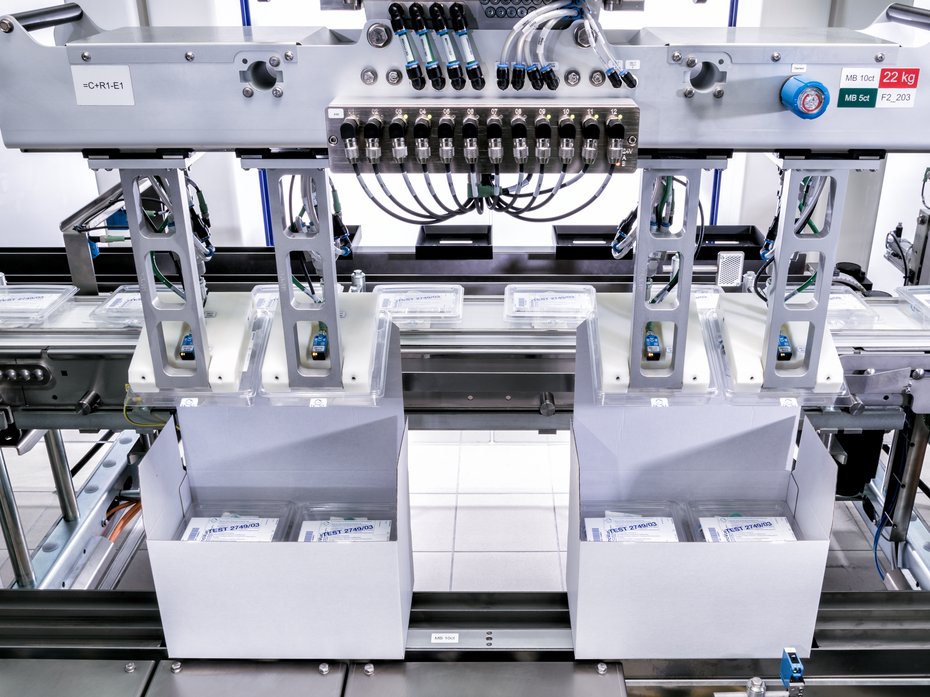

10. Close: Clamshells

10. Close: Clamshells

A TLM-F2 robot takes the clamshells from the Transmodul and places them onto a closing station, partially closing them. Another TLM-F2 robot folds the clamshell lid with a closing clip and fully seals them. The sealed clamshells are then transferred onto the discharge conveyor. Incorrect clamshells are rejected.

11. Label: Clamshells

11. Label: Clamshells

Finally, up to three labels are applied to the clamshell. A camera inspects the printing on the labels.

Facts about the

Combination Cartoner

From a customer project:

- Products: syringe, vial, leaflet, plunger, mini-spike (US or EU version)

- Infeed: 65 products per minute

- Output: 65 clamshells per minute

- Labeling: container label with variable data

- Tamper-evident label for product integrity

- Optional Bollini label or vignette

- Cartoning: 5 or 10 combo kits per carton

Questions about

Combination packaging?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com