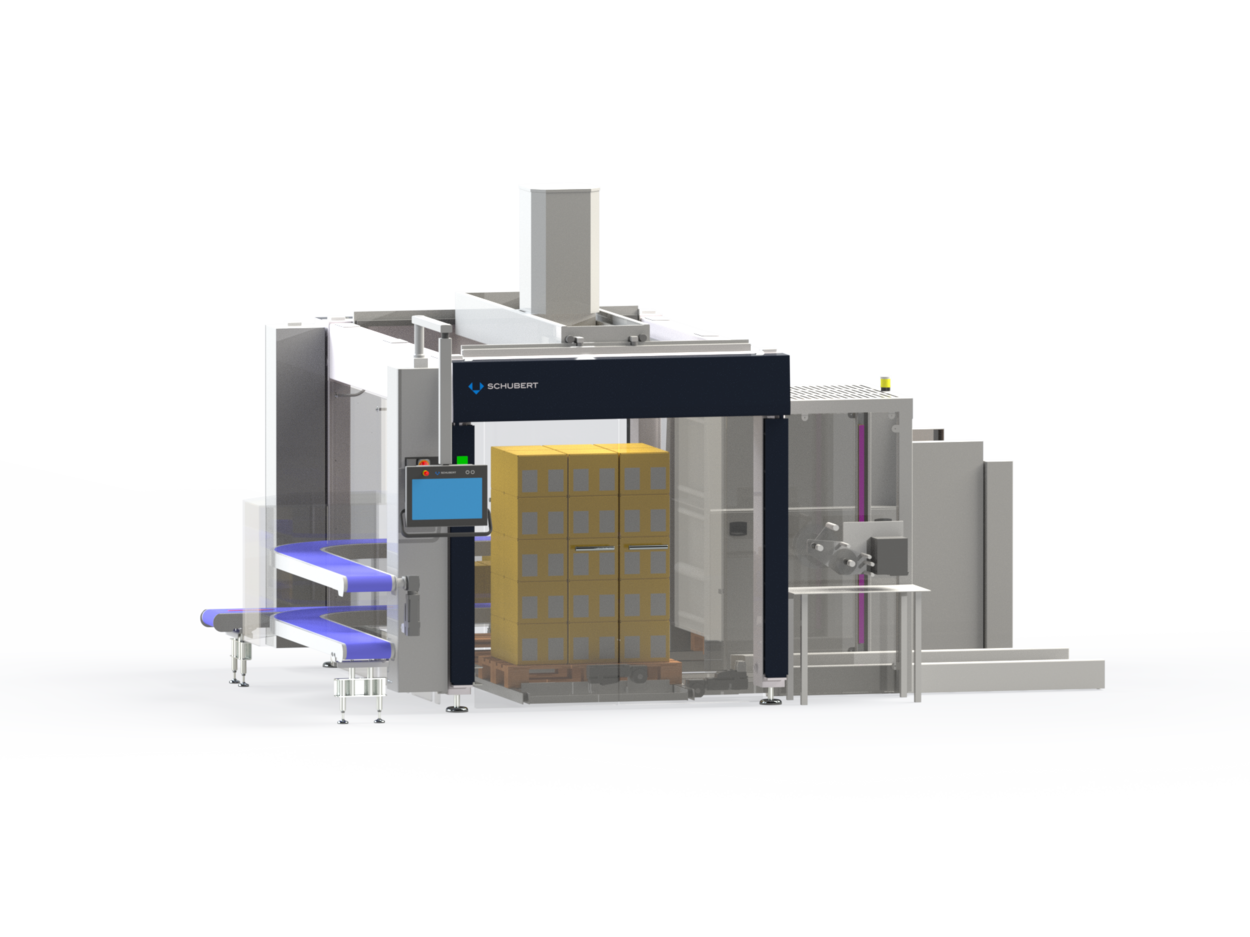

Palletizer Process Solution

Our palletizers handle the automated stacking of cases onto pallets – precisely positioned, stable in form and optimized for transport and warehouse logistics.

Suitable for:

- Transport

- Warehouse logistics

- Standardization

- Protection

Process steps at a glance

Our machines are modular in design and cover all key functions of pharmaceutical packaging – from product handling to palletizing. Here you get a structured overview of the individual steps and how they interact within your machine.

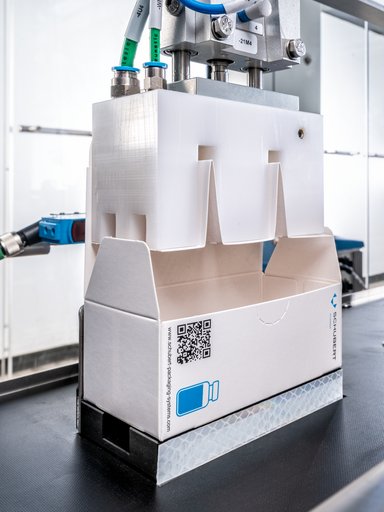

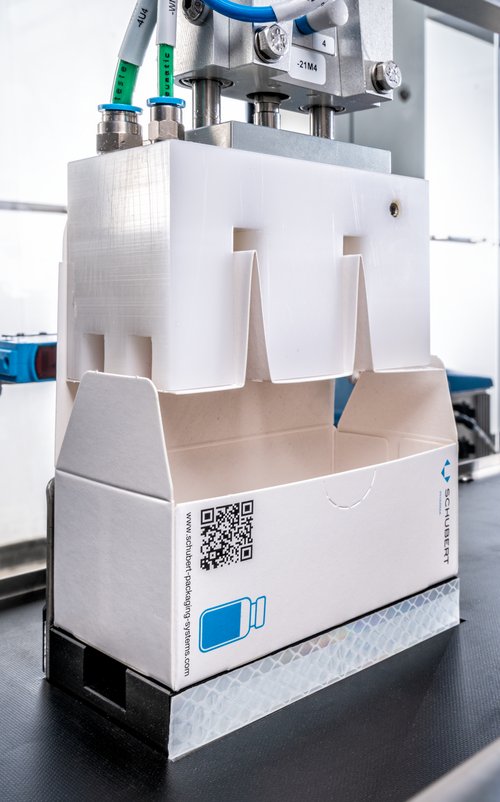

1. Infeed: RSC carton

1. Infeed: RSC carton

The sealed RSC cartons are conveyed in a single lane to the transfer position of the TLM-P4 robot.

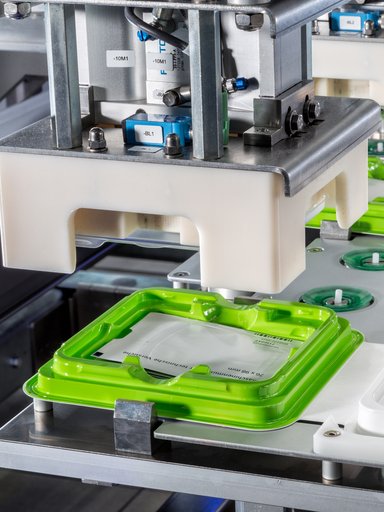

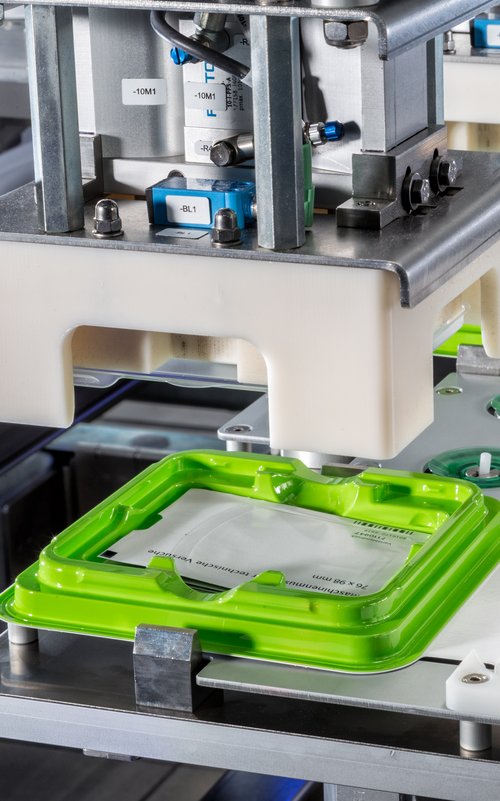

2. Label inspection: RSC carton

2. Label inspection: RSC carton

A camera system checks the label contents to prevent mix-ups and to ensure correct aggregation of the serialized data. Incomplete cartons are detected, rejected and can be reintegrated into the process after manual reworking.

3. In-process control: RSC carton

3. In-process control: RSC carton

At defined intervals, or manually if required, an RSC carton can be diverted for visual inspection and then returned to the process.

4. Infeed: Pallet

4. Infeed: Pallet

Empty Euro pallets are fed into the magazine via a lift, separated, and transported to the palletizing station.

5. Palletizing: RSC carton

5. Palletizing: RSC carton

The TLM-P4 robot stacks the inspected cartons onto the pallet according to the palletizing pattern.

6. Labeling / Outfeed: Pallet

6. Labeling / Outfeed: Pallet

After palletizing is complete, a label with static and dynamic data is generated automatically. The operator manually applies the label and registers the pallet to the customer’s MES system using a handheld scanner.

Questions about

our palletizer?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com