#SuccessStory #Bottles Sensitive Human Plasma Preparations – Reliably and Safely Packaged

- Maximum safety ensured through multiple visual inspections

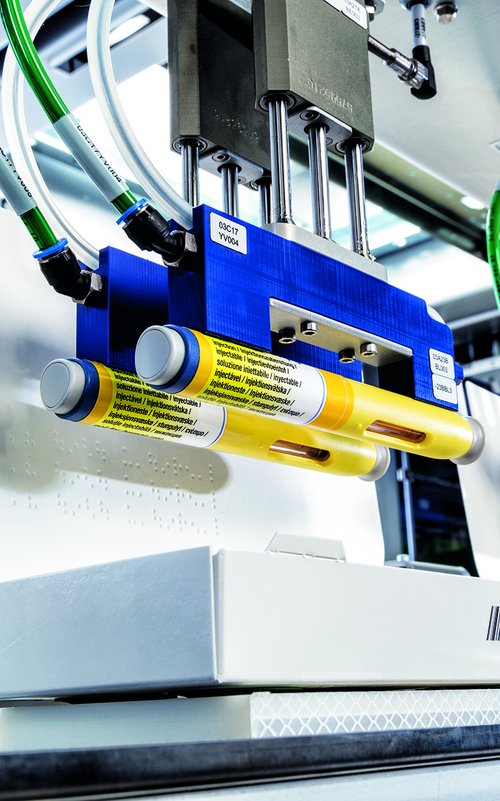

- Tamper-proof labeling with process-stable color-shift ink

- Seamless integration into the company’s MES (Manufacturing Execution System)

200

Products per minute

10

Verpackungs-

zusammenstellungen

Requirement

Pharmaceutical packaging in a fully integrated, compact system

Pharmaceutical packaging is a highly sensitive and demanding process – one of the most advanced disciplines in packaging technology. The stringent safety requirements to effectively protect against product mix-ups or tampering often necessitate additional process steps that are typically only offered by specialized providers. For CSL Behring AG in Bern, Schubert-Pharma engineered a compact system in which all packaging steps are seamlessly combined. From product labeling and cartoning to final pharmaceutical palletizing, every stage of the process is fully integrated into the company’s Manufacturing Execution System (MES).

Driven by its mission to save and improve lives, CSL Behring specializes in biotherapeutics for the treatment of rare and serious diseases. Over more than 100 years of success, the parent company CSL Limited – to which CSL Behring belongs – has grown into one of the world’s leading biotechnology firms. Today, CSL offers the broadest portfolio of plasma-derived and recombinant therapies in the industry. The company is particularly committed to patients with blood disorders and immunological conditions, while its therapies are also used in other rare diseases. Recognized multiple times for its pioneering work, CSL places the highest priority on modern and forward-looking working conditions. With the latest modernization of its packaging processes for shipping-ready pharmaceutical products, CSL Behring once again placed its trust in the expertise of Schubert-Pharma. The new system now packages two vial sizes in ten different configuration variants – all in compliance with the highest pharmaceutical safety standards.

Solution

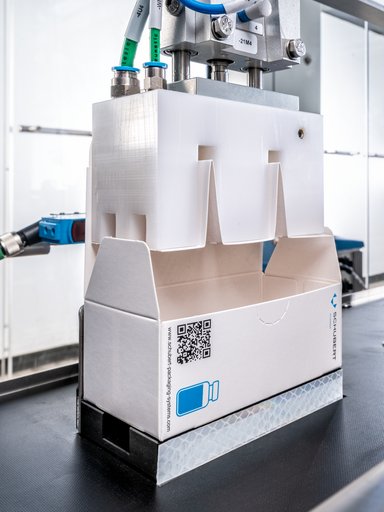

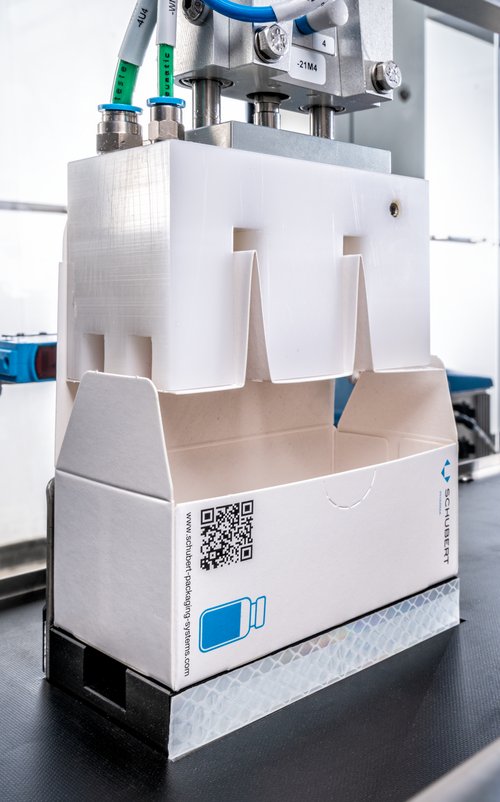

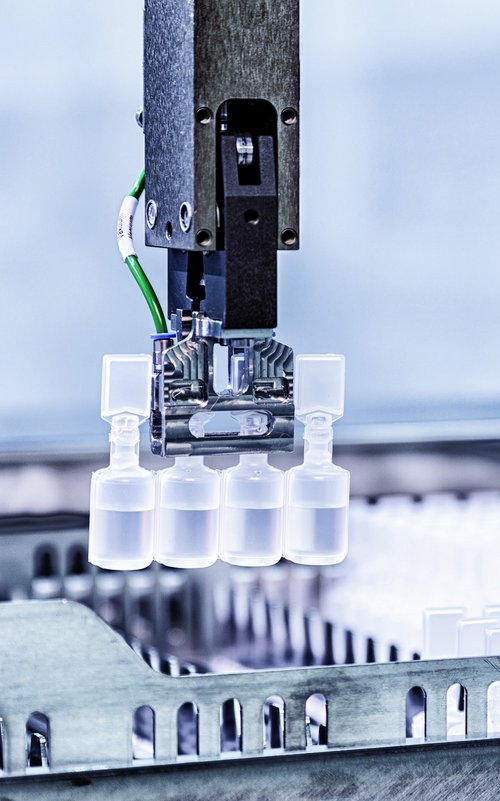

The main challenge was to integrate the various packaging formats and container sizes of the sensitive pharmaceutical products into a compact, user-friendly packaging line – without compromising the stringent pharmaceutical safety requirements. Both 50- and 100-milliliter vials were to be packed first into individual cartons and then into shipping cartons.

In addition, the often extensive and varying booklets with product information had to be reliably inserted into the individual cartons. By combining two Transmodul conveyors and fully integrating the line into CSL Behring’s Manufacturing Execution System (MES), Schubert-Pharma created a packaging solution that ensures absolutely reliable and secure handling of the delicate human plasma products in both vial sizes – ready for shipment.

The system also stands out in terms of space efficiency and its standardized, intuitive operating concept – a hallmark of Schubert technology. Another key advantage is the reduced spare parts inventory required, which in turn lowers maintenance effort and cost.

"The process-stable laser printing with a color-change coating, combined with the various legally compliant, tamper-evident labelings and the packaging material, posed a real challenge. However, in close collaboration with the laser supplier and the packaging material manufacturer, the team was able to develop a highly effective, tailored solution through several iterative cycles."

Tamara Huber, Projectmanager

CSL Behring

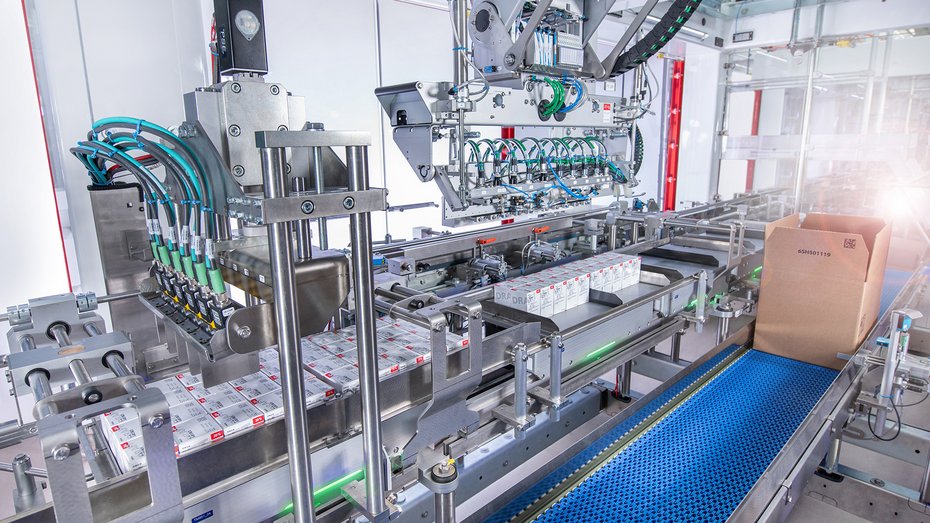

Compact All-Rounder

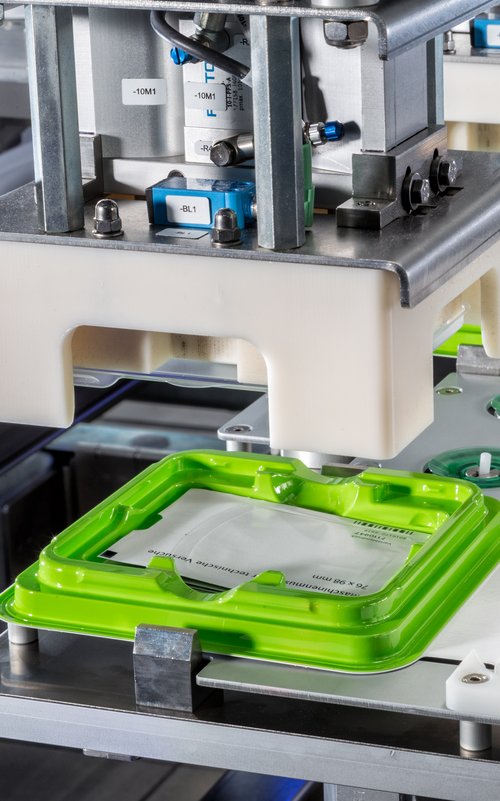

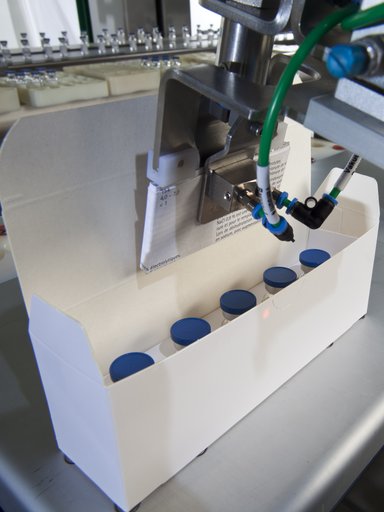

The delivered solution is a space-saving cartoner consisting of five TLM frames, reliably integrating all process steps into a single line. Two Transmodul tracks connect the individual processes efficiently. First, the cartons are erected and the booklets inserted. In parallel, the already labeled vials are fed via a conveyor. Four F4 robots pre-group the vials on a Transmodul, which then moves to the filling station. Eight cartons are loaded simultaneously at the filling station. After sealing, three laser printers apply the various required markings.

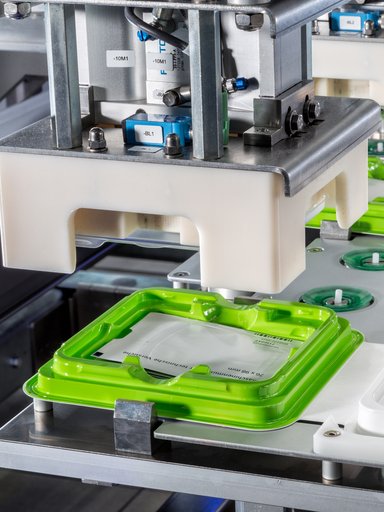

Complete Control

To ensure safe and reliable packaging, the line is fully integrated into the company’s MES (Manufacturing Execution System), including serialization and aggregation. In line with high quality and safety standards, visual inspections are conducted at critical points throughout the packaging process, using Schubert’s proprietary vision system. In addition, multiple code-reading devices verify that the labeling of sensitive products is correct and that each item is properly assigned to pre-inspected secondary packaging.

Everything in the paintwork

Another challenge was ensuring a stable laser marking process. The special color-change coating had to be fully compatible with various legally compliant, tamper-proof labeling methods as well as the packaging material. Thanks to the strong interdisciplinary collaboration between Schubert experts, the laser supplier, and the packaging material manufacturer, a dedicated solution was developed. It consistently meets the high security requirements and also offers potential for future enhancements.