#SuccessStory #Kits Lean Packaging for Weight Loss Product

- 12 machines form a fully integrated packaging line

- Logical sequence from individual functions to a stable, reliable packaging process

- Integration of all control functions and data capture systems, compliant with CFR Part 11 requirements

- Format changes achievable within 10 minutes

- Currently designed for two product formats: Starter Kit with 75 ml cans and Refill Pack with 150 ml cans

- Comprehensive validation according to IQ & OQ guidelines

100

Combination Kits per minute

2

Bottle sizes

(75 ml and 150 ml)

Requirement

Schubert-Pharma developed a fully integrated packaging line for the pharmaceutical manufacturer of a weight loss product, designed for multi-component packaging with visually appealing presentation.

Originally a prescription-only weight-loss medication, lower-dosed versions were already available in some countries as OTC products sold through supermarkets and drugstores. Following FDA approval for the U.S. market, the manufacturer aimed to increase production capacity. Alongside growing demand, an attractive and marketable product appearance was also a key consideration.

Solution

In addition to depalletizing the top and bottom parts, inserting and filling trays, the turnkey project also included labeling, coding, and shrink-wrapping. The twelve workstations culminate in the final packaging, including palletizing and pallet securing—fully automated by Schubert-Pharma. The line produces up to 100 kits per minute, and format changes are completed in just ten minutes.

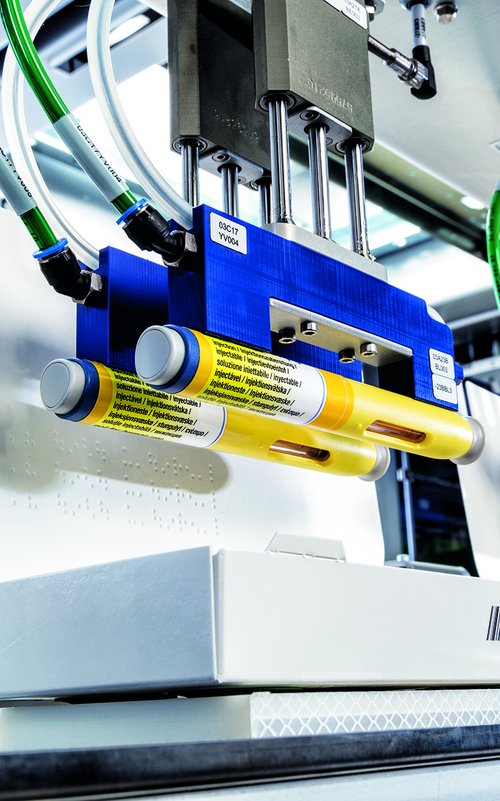

The Schubert-Pharma experts structured individual functions into a logical workflow, interconnecting control systems, data generation, and processing. This ensures a continuously stable and flawless packaging process in daily operations. For example, when a user opens the package for the first time, the label on the plastic bottle must be immediately legible. To achieve this, the container is rotated in an alignment station until optical controls confirm the correct label orientation. Only then does the robot arm pick up the container and place it in the tray in the precise orientation.

The perfect presentation of the brand lettering on the plastic containers is ensured through optical inspection.

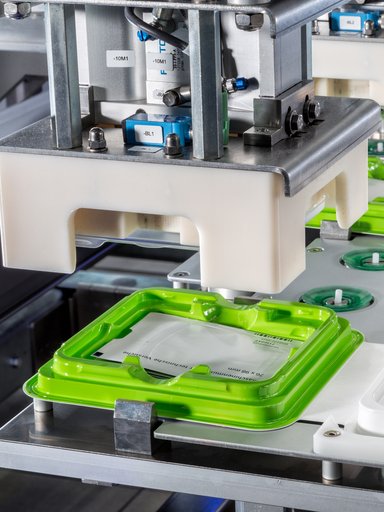

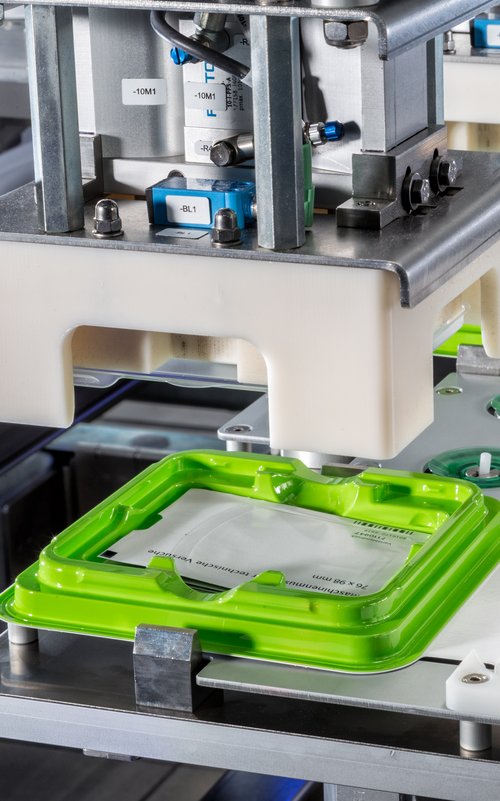

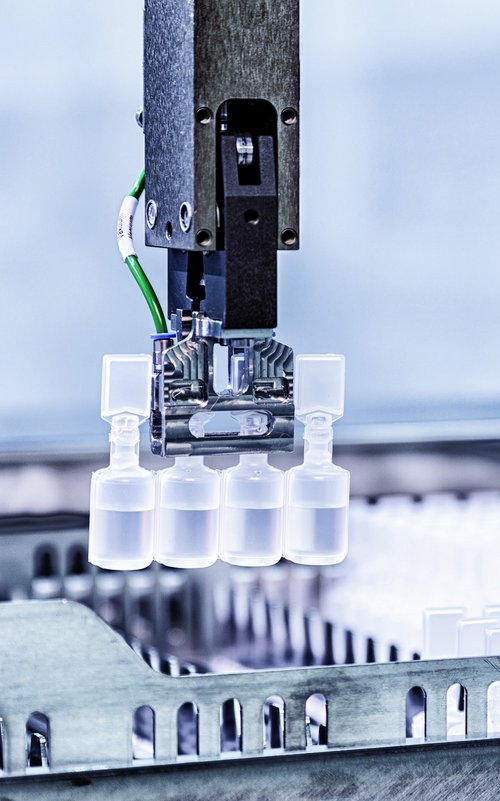

Tray Loading

The tray, previously placed into the forming part, is then loaded: the daily dose containers are automatically separated and transported to the picker station for optical image recognition. The leaflet is inserted before the plastic containers, which arrive at the picker station in an upright position. Before being transferred, the containers are rotated into a horizontal orientation – to ensure perfect product presentation, two rollers rotate the containers until an optical inspection confirms the correct alignment of the brand lettering. Afterward, the booklet is inserted, and the tray is closed with a lid.

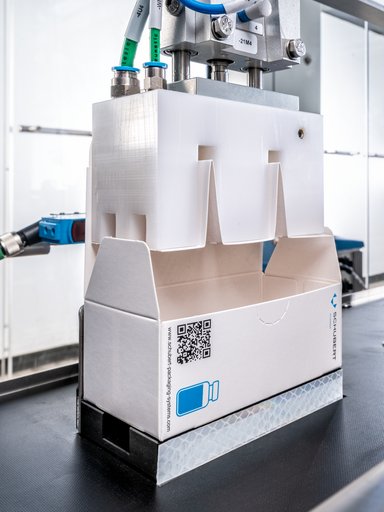

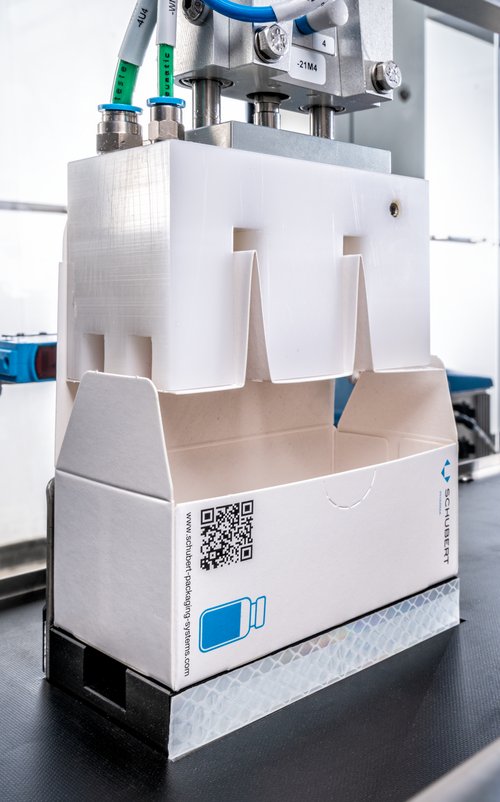

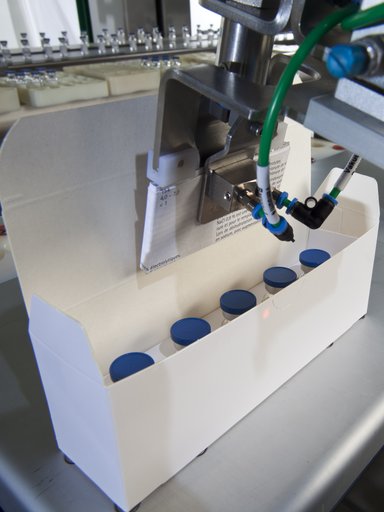

Labeling and Cartoning

At the next station, the trays are labeled at defined positions on the top and bottom. Correct alignment is crucial for an optimal product presentation and ensures that the printed barcode is always in the exact same location. An optical inspection verifies this and automatically rejects any faulty packages. The trays are then wrapped using a flow-wrapping technique.

Next, cartons are erected and the trays are placed inside the shipping cartons. In the palletizing area, the cartons are stacked in multiple layers onto pallets. The pallets, secured with shrink wrap, then leave the line.