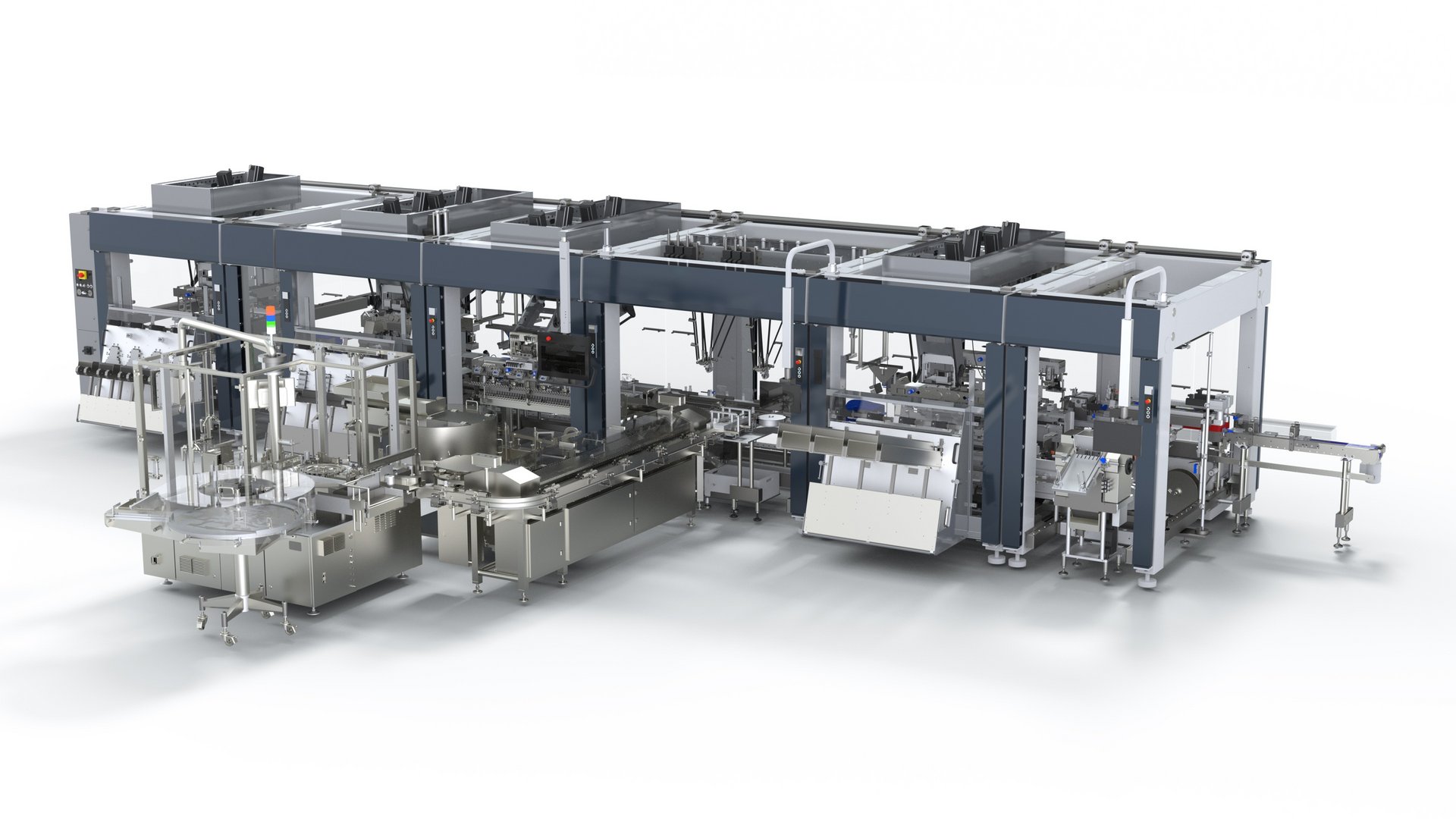

Ampoule packaging

- Careful handling of delicate glass ampoules

- Accurate product feeding possible through an innovative transport system

- Flexible processing of various inner partitions with universal tooling

- Ensuring all product and packaging tolerances

- High process reliability through visual inspection

Special features of ampoules

Ampoules require special care during packaging. Schubert machines ensure break-proof handling through precise robotic technology and sensor-assisted singulation. This technology is ideal for small batches and varying formats.

1. Erecting the carton

1. Erecting the carton

2. Erecting the insert

2. Erecting the insert

3. Infeed Ampoules

3. Infeed Ampoules

4. Load Ampoules

4. Load Ampoules

5. Infeed, Folding and Load the Leaflets

5. Infeed, Folding and Load the Leaflets

6. Sealing and labeling the carton

6. Sealing and labeling the carton

7. Discharge carton

7. Discharge carton

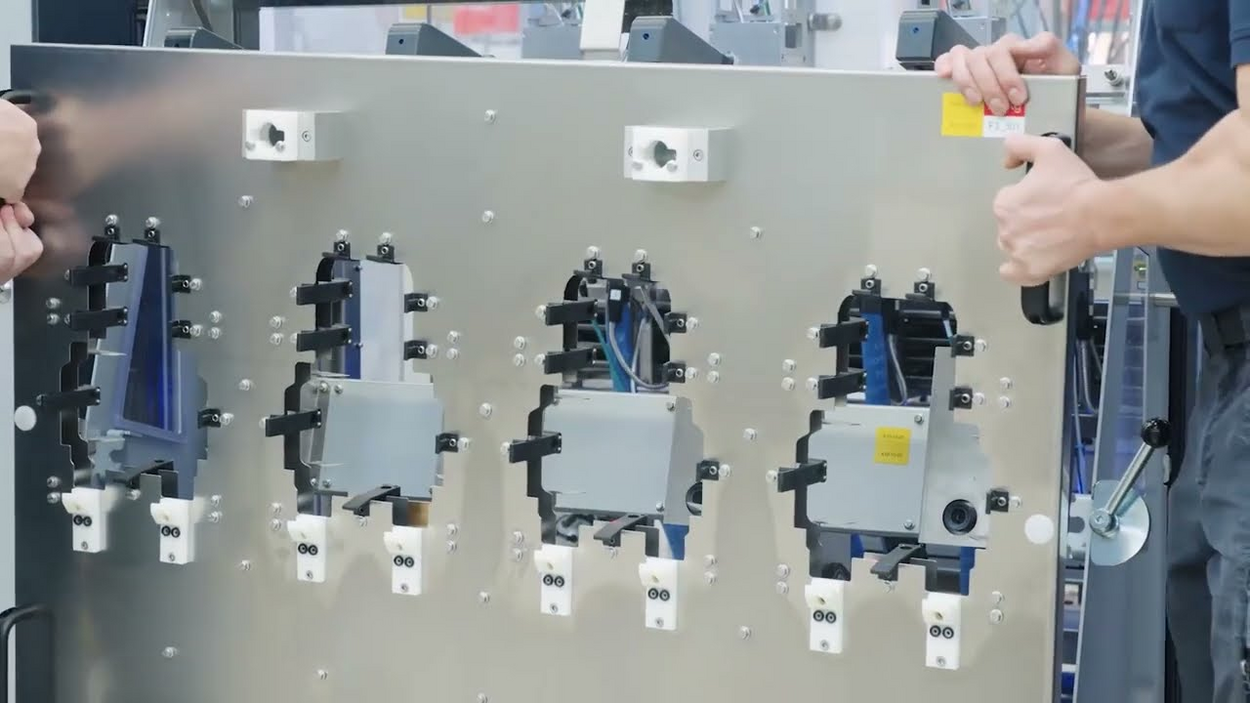

Format change

Quick format change

Quick format changes are crucial for efficient production processes, especially with frequently changing packaging formats. In Schubert pharmaceutical packaging machines, format changes take approximately 30 minutes – entirely tool-free and supported by our plug-and-play philosophy. Coded format parts and RFID detection ensure error-free format changes.

Adjustable or custom-designed tools also provide maximum flexibility for frequently changing formats. The result: reliable processes, minimal downtime, and consistently high packaging quality.

Facts about the

Ampoule Cartoner

From a customer project:

- Up to 450 ampoules per minute

- Minimal work-in-progress thanks to an intelligent transport system

- 17 different formats on a single machine

- Folding of package inserts as well as processing of pre-folded booklets

Questions about

Ampoule packaging?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com