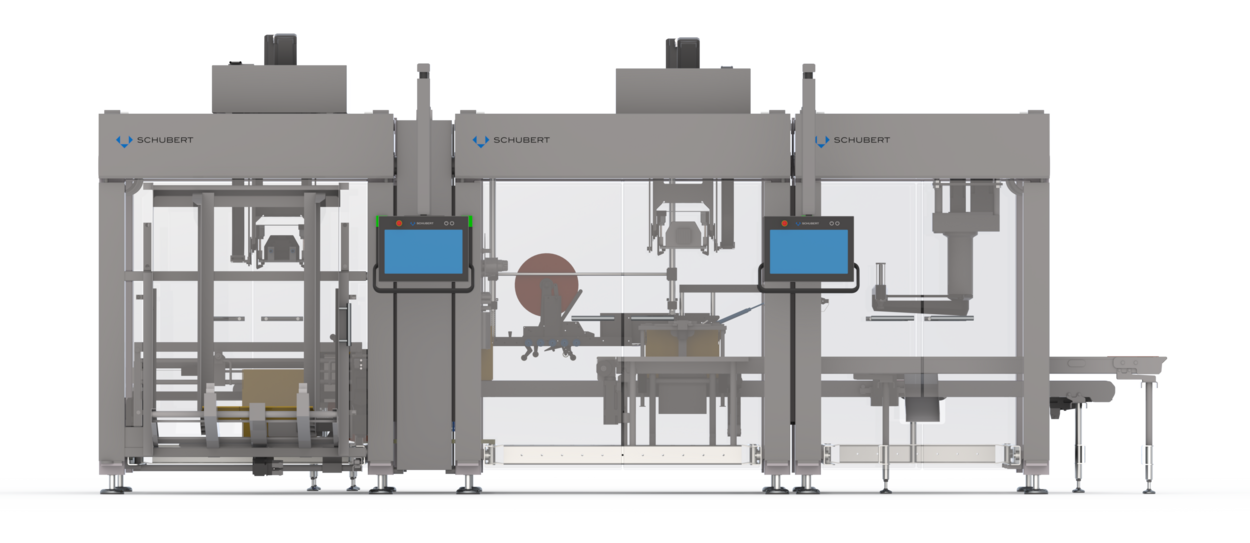

Case packer Process Solution

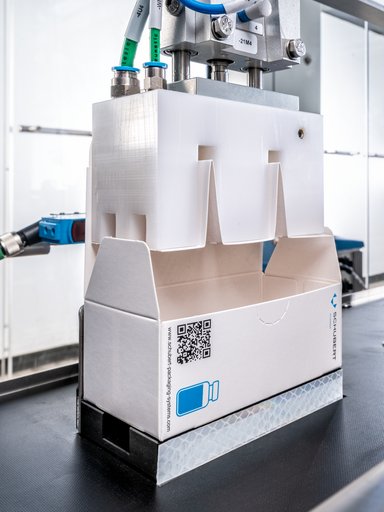

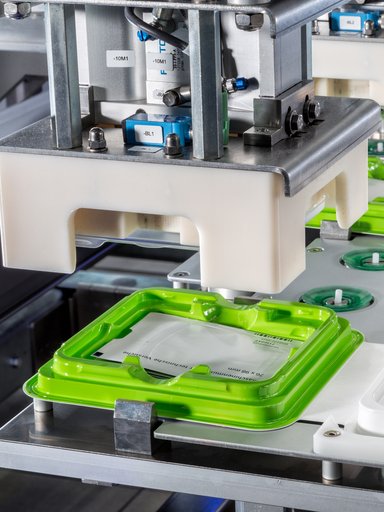

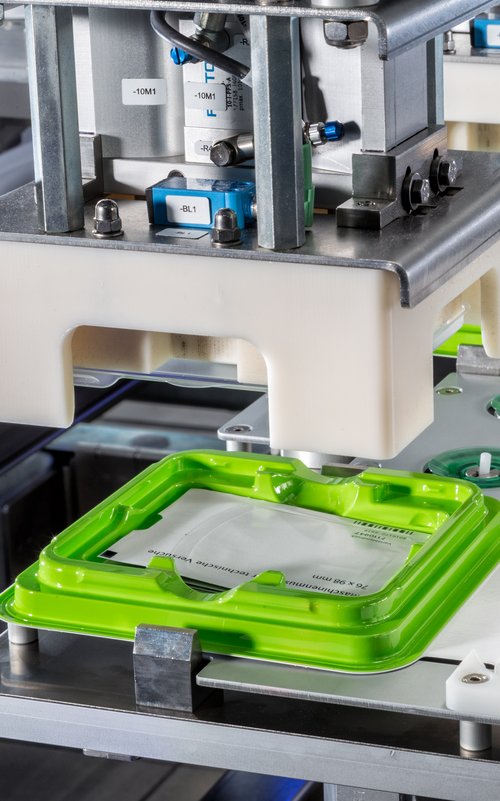

Our case packers form secondary and transport packaging such as wrap-around and RSC cartons as well as trays with or without lids – precisely erected, filled and sealed for efficient, shelf-ready shipping.

Suitable for:

- Wrap-around

- RSC carton

- Tray with lid

- Tray without lid

- Shelf-ready solutions

- Plastic crates

- Reusable crates

Process steps at a glance

Our machines are modular in design and cover all essential functions of pharmaceutical packaging – from product handling to palletizing. This gives you a structured overview of the individual steps and how they interact within your machine.

1. Infeed: Carton

1. Infeed: Carton

The cartons are fed in single file from the upstream machine to the system via an infeed conveyor.

2. Rejection: Carton

2. Rejection: Carton

On the infeed conveyor, the variable data on the carton is checked. If the data is incorrect, the TLM-F4 robot rejects the carton into a designated bin.

3. Pre-grouping: Carton

3. Pre-grouping: Carton

If the data is correct, a TLM-F4 robot takes the cartons from the infeed conveyor and transfers them onto a grouping conveyor. There, the individual cartons are pre-grouped into formations depending on the format.

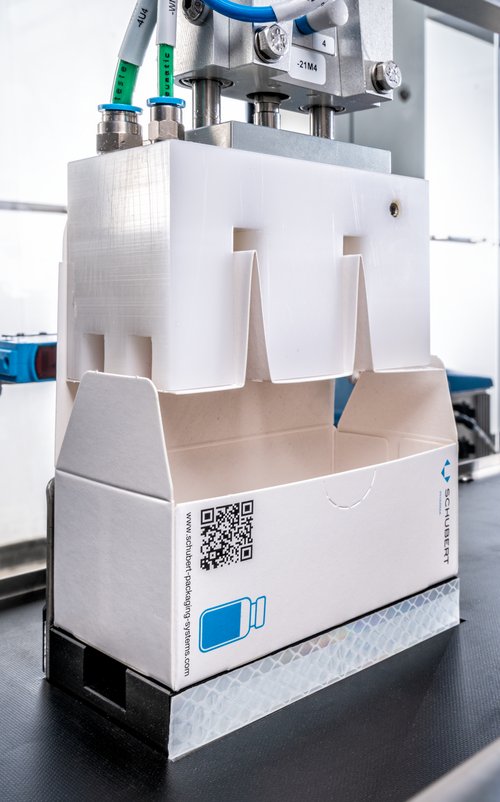

4. Forming: Carton

4. Forming: Carton

The pre-glued blanks (RSC) are stored in a magazine. The TLM-F2 robot removes the blanks from the magazine and erects them. The bottom flaps are folded, sealed with adhesive tape and then placed onto the conveyor.

5. Labeling: Carton

5. Labeling: Carton

The carton is labeled on the side. The label is printed with variable data and serial data. A corresponding camera then verifies the data on the applied label.

6. Loading: Carton

6. Loading: Carton

A TLM-F2 robot takes the pre-grouped cartons from the grouping conveyor and places them layer by layer into the erected carton until it is completely filled. A centering frame ensures precise positioning of the cartons inside the case.

7. Rejection: Carton

7. Rejection: Carton

If a carton is not correctly filled (e.g. serialization error, incorrect placement, etc.), the entire carton is diverted to the rejection station. There, the carton can be manually removed from the conveyor.

8. Closing / Outfeed: Carton

8. Closing / Outfeed: Carton

If a carton is correctly filled, it is transferred to the outfeed conveyor. There, the top flaps are automatically folded in and the carton is sealed with adhesive tape. The carton then leaves the case packer on the outfeed conveyor.

Questions about

our case packer?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com