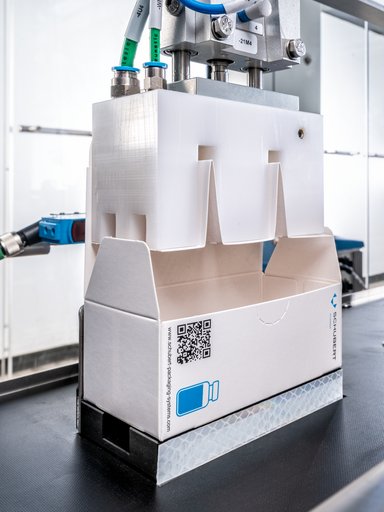

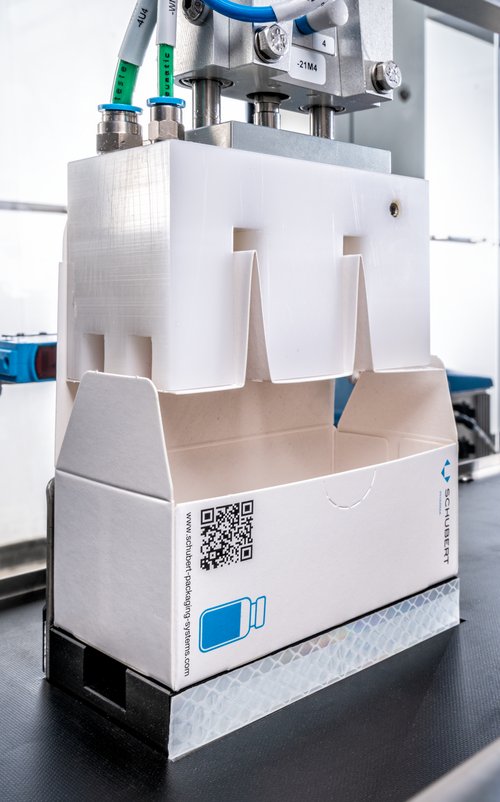

#SuccessStory #Patches Appealing Packaging Design for Easy Handling

- Eye-catching and user-friendly packaging design

- Fully automated packaging process

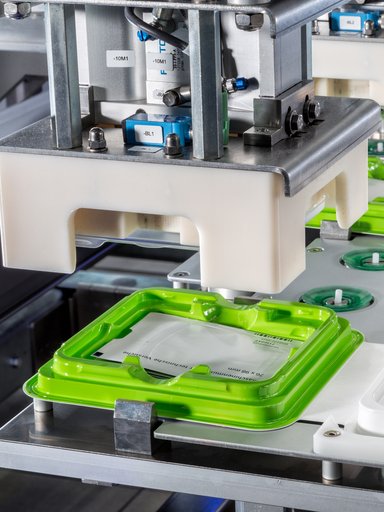

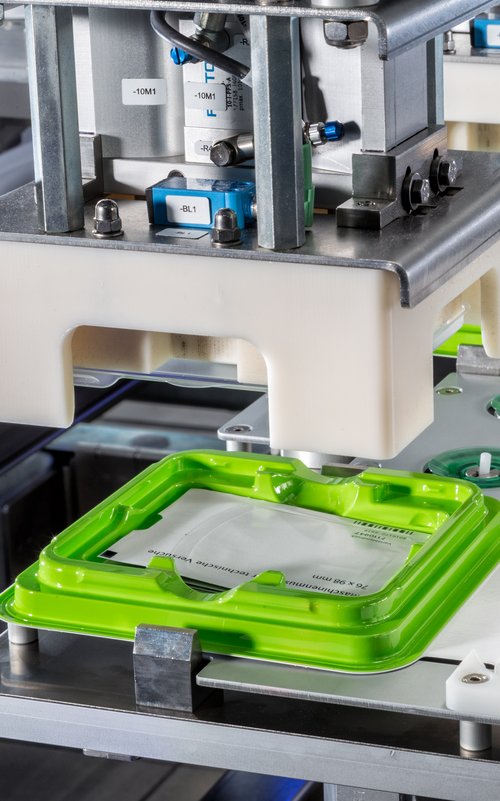

- High-quality sealing of trays

- Various tray insert geometries for product protection

- Tray sealed with cardboard lid

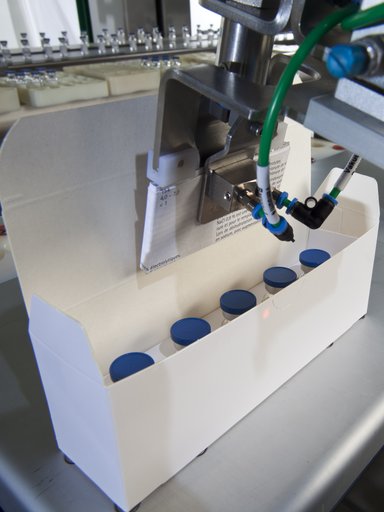

- Packaging with unique serial number for traceability

- Transmodul technology in use for efficient product handling

40

Packages per minute

Patch

in different sizes

Requirement

Pharmaceutical Product Packaging:

Schubert-Pharma impressed LTS Lohmann Therapie-Systeme AG with an attractive packaging design and fully automated process.

On behalf of a Belgian client, LTS Lohmann Therapie-Systeme AG, acting as a contract packer, was tasked with completely redesigning the final packaging concept for an active-ingredient patch. The goal was to enable patients to handle and apply the product more easily.

Schubert-Pharma developed a new packaging design that balances an appealing presentation with efficient machine operation. The result is a fully automated packaging process that also ensures precise counting of seal-edge pouches and additional weighing of the pharmaceutical products.

Solution

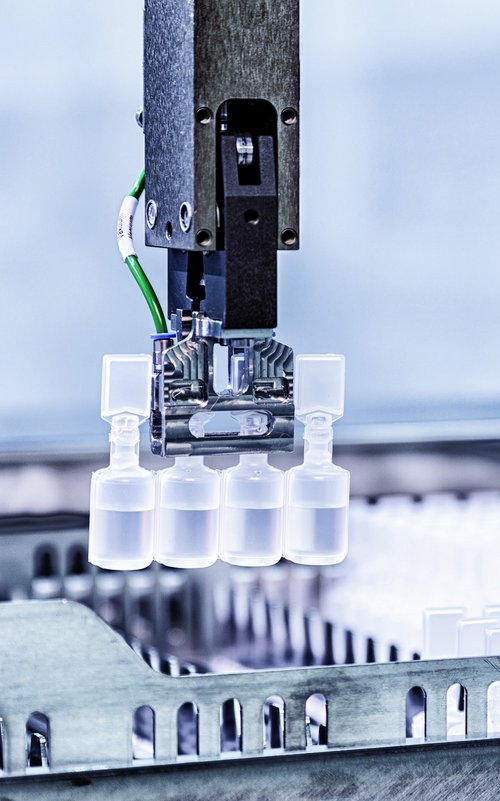

The TLM packaging machine at LTS assembles the various individual components—such as lid and base trays, cardboard inserts, plastic covers, and the patient information leaflet (PIL)—into an appealing final package.

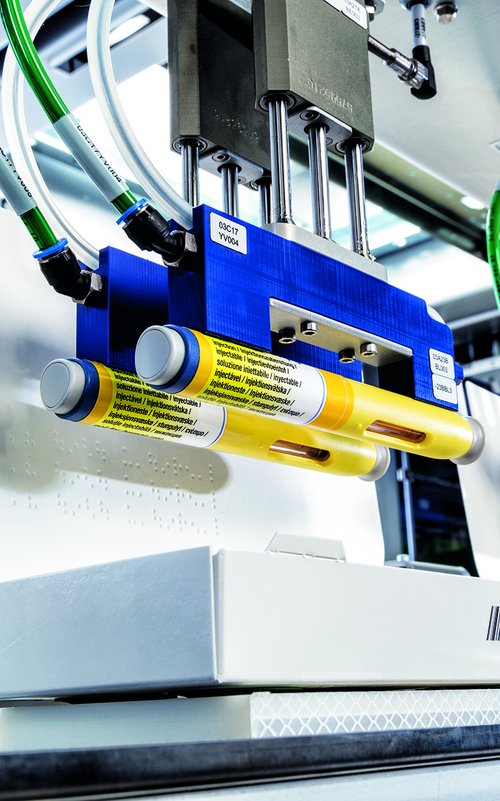

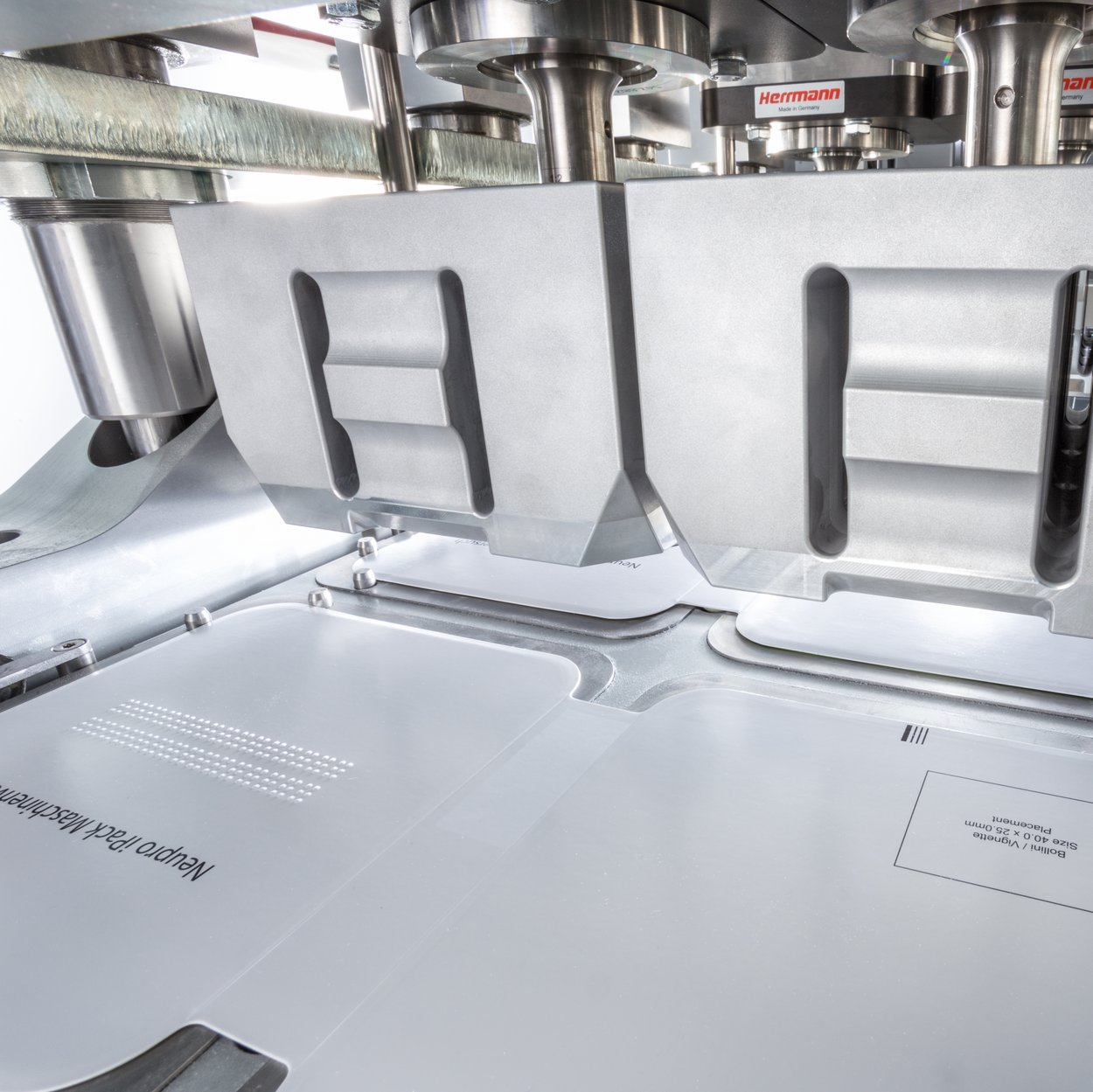

To fill the trays with patches sealed in peelable pouches, Schubert-Pharma integrated multiple machine modules into a single, closed system. For a visually flawless seal between the trays and cardboard inserts, Schubert-Pharma implemented an efficient ultrasonic sealing solution, fully integrated into the TLM line. Additional formats of peelable pouches and trays can also be processed on the same machine.

“With the TLM, we have a technologically advanced and tailor-made solution that allows us to efficiently produce and fill a sophisticated packaging.”

Sebastian Eichholz, Project Engineer

LTS Lohmann Therapie-Systeme AG

Excellent Sealing Quality

Outstanding sealing quality between trays and carton inserts is achieved through ultrasonic sealing using a block sonotrode. This approach enables simpler handling and lower life-cycle costs, resulting in long-term savings. Each block sonotrode can be individually and easily configured via the Schubert operator terminal. The independent control of the block sonotrodes allows for precise monitoring of the quality of each seal.

Easy Format Change

Different sizes of the peel-seal bags, as well as various tray cavities and colors, can be switched quickly: Despite varying patch sizes, only the loading tool on the F2 robot needs to be adjusted. All other tools are universally designed for all packaging sizes, eliminating the need for additional format parts.