#SuccessStory #Combi Kits Efficient All-in-One Packaging Solution

- Turnkey solution: loading clamshell trays, labeling, and cartoning

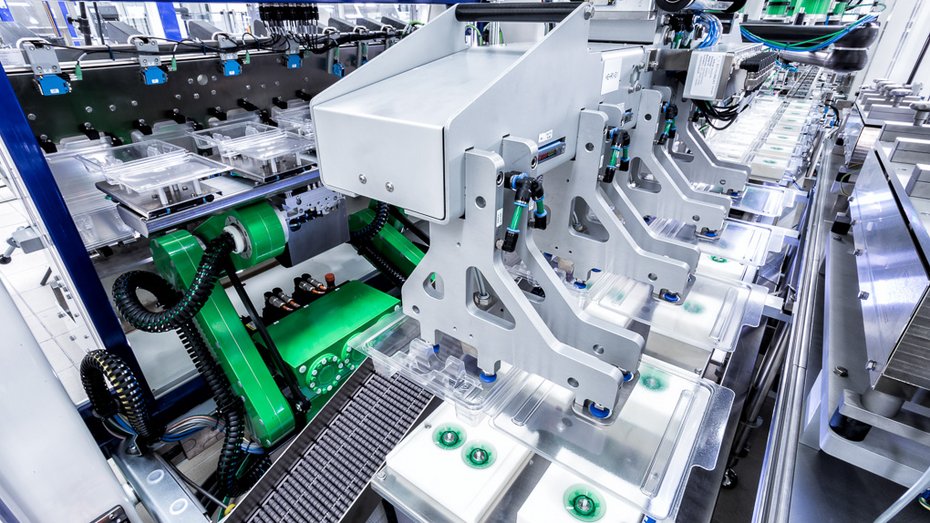

- Transmodul in operation

- Complete system from a single source

- Efficient feeding and loading of various individual components

- Precise singulation and accurate alignment of components

- Labeling

50

Kits per minute

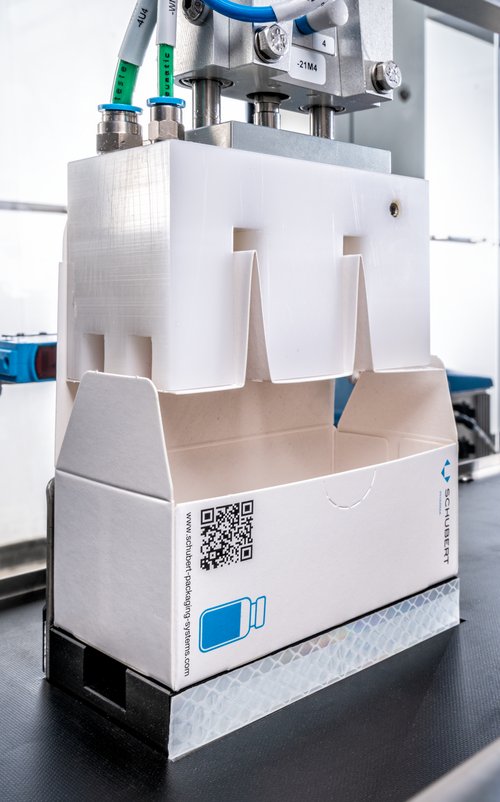

5 or 10

Kits per carton

Requirement

Efficiency and product safety at the forefront:

An Italian pharmaceutical company fully automated its previously manual packaging processes with a turnkey solution, including a complete packaging line, supplied by Schubert-Pharma.

The system packages a multi-component combination kit containing contrast media for ultrasound examinations. This task requires not only precise singulation and accurate alignment of the components but also the integration of a centralized communication system for product serialization.

With the turnkey solution provided by Schubert-Pharma, the company received a complete system from a single source. This allows the pharmaceutical manufacturer to increase capacity, reduce labor costs, and ensure that its validated processes remain fully compliant and reliable.

Solution

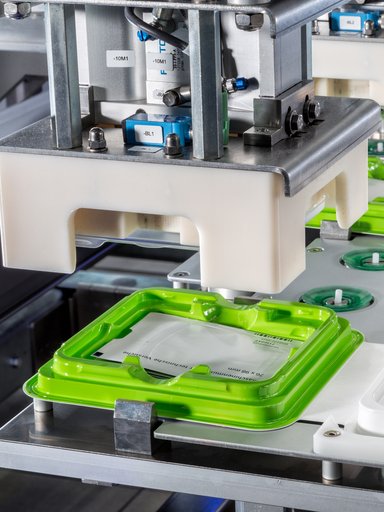

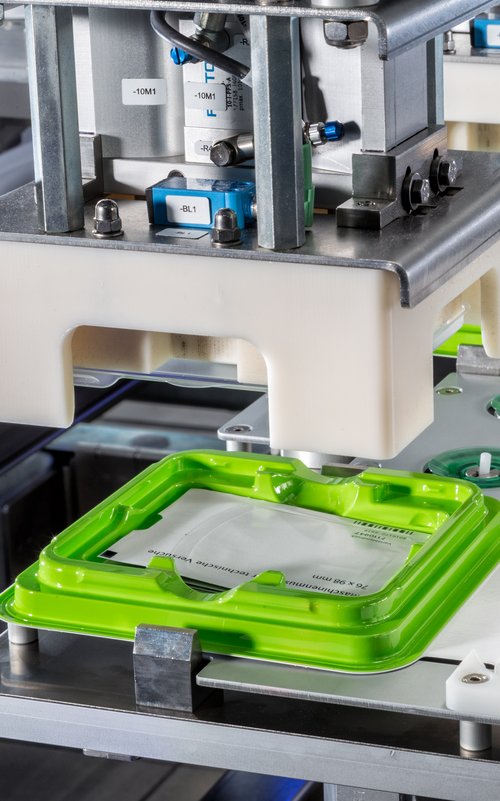

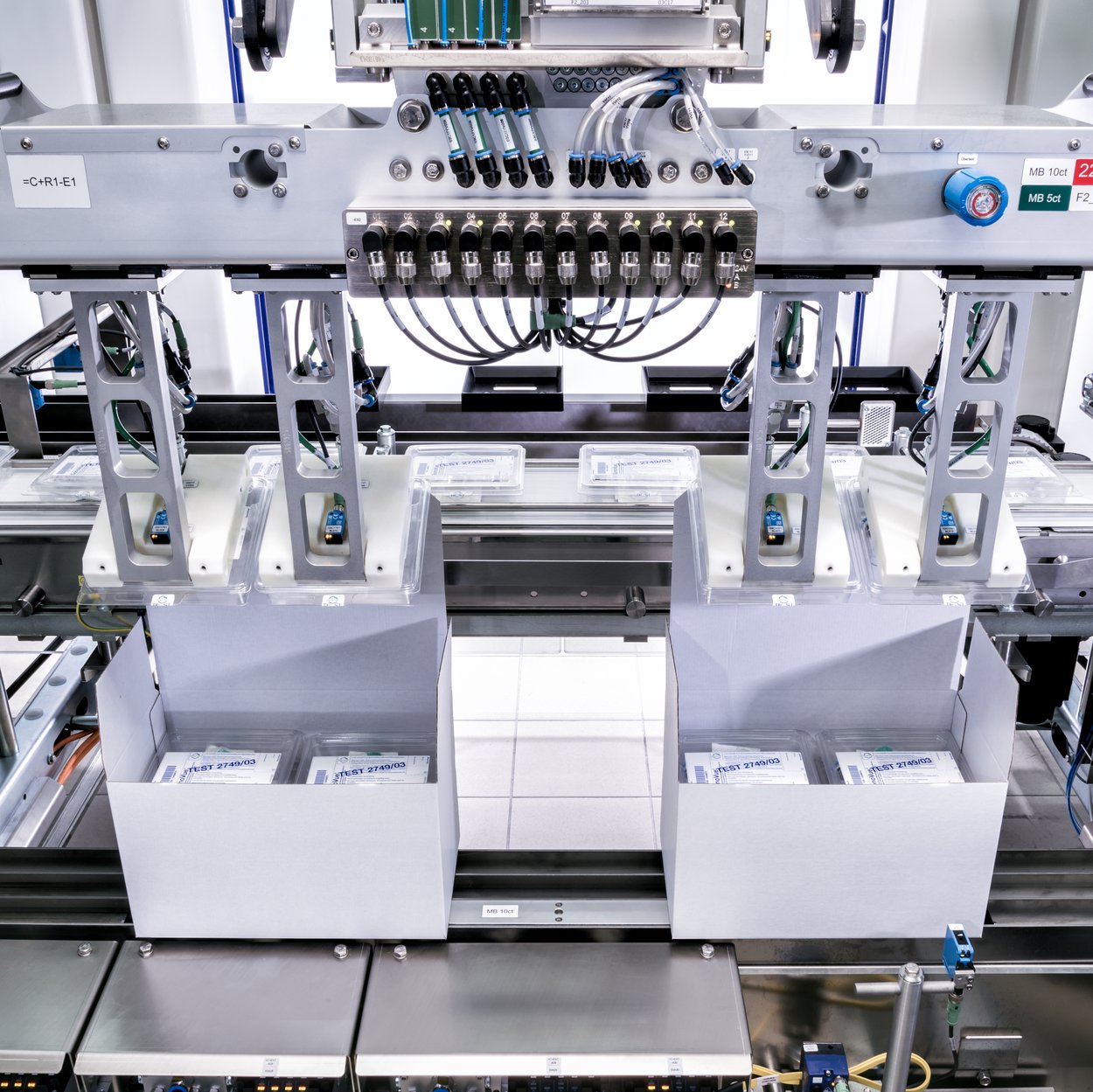

The fully automated packaging process consists of three main operations: loading and labeling the trays, followed by their cartoning into multi-boxes. Precise placement and securing of each individual component within the trays, achieved through customized robotic tooling, ensures gentle and damage-free product handling.

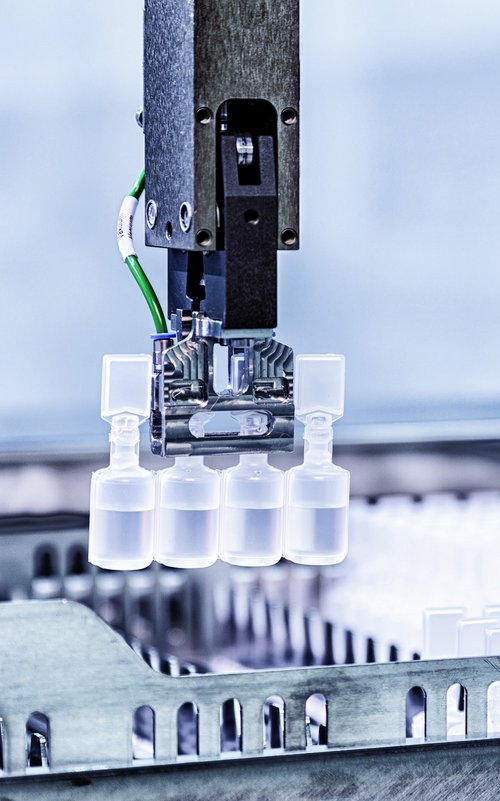

The integrated overarching communication system guarantees traceability and prevents batch mixing: barcode scanners and cameras verify the data on each product label before placement into the clamshell trays. As part of the turnkey solution, Schubert-Pharma also efficiently integrated the feeding systems for all individual components into the overall machine concept.

"The machine impressed me from the very beginning. We anticipate increasing production volumes in the future. I am already looking forward to seeing how our machine – which we internally call 'Mustang' – will continue to excel."

Site Manager of the Customer

Feeding and Loading

At the start, the clamshell trays are taken from the magazine, destacked, and positioned on the Transmodul. Leaflets are subsequently removed from the same magazine and placed into the trays, making this combination within a single magazine highly space-efficient.

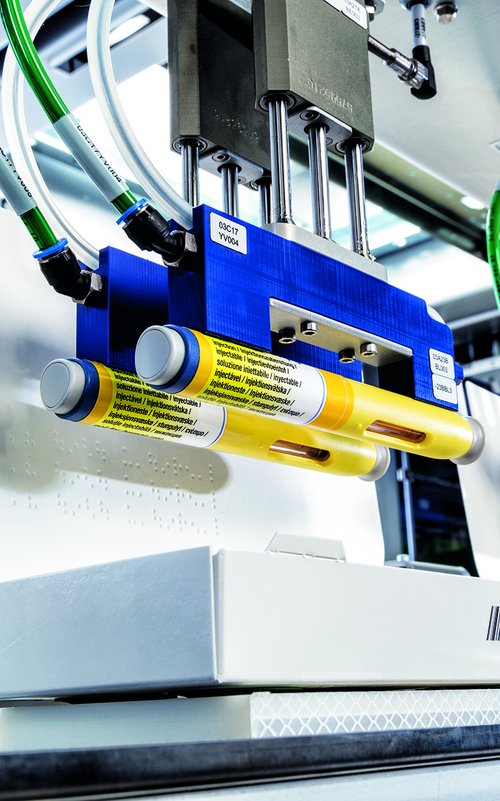

Next, a pick-and-place robot inserts the first component of the combo kit – a plunger rod – into the tray. Transfer systems then feed the second component, which is singled out and positioned by an F4 robot in front of a camera for data verification. If the label data matches the specified requirements, the component is placed into the clamshell tray.

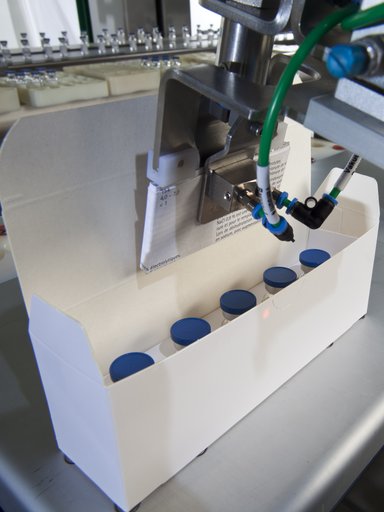

In the following module, a rotary table supplies the vials containing the lyophilized contrast agent to the system. An F4 robot positions the vials on a rotating station in front of a camera, which reads and verifies the variable data on the label. Once confirmed to match the current production batch, the robot loads the vial into the tray. The next component – a filled syringe – is only placed in the tray after successful verification of its label data.

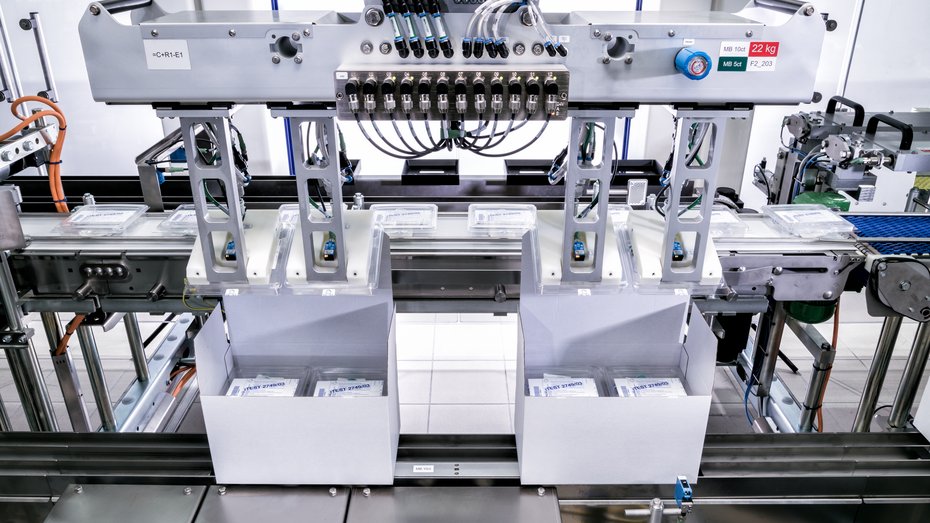

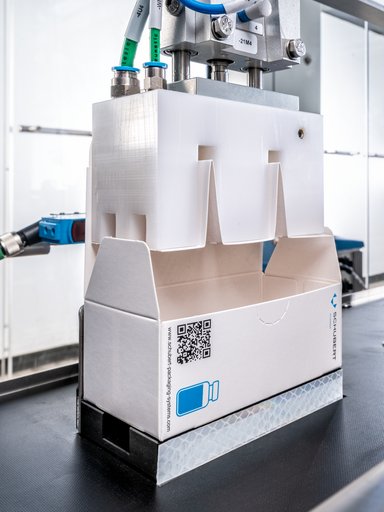

Closing and Cartoning

A stand-alone labeling unit applies up to three labels after the clamshell trays have been loaded and closed. The subsequent cartoning process begins with destacking the carton blanks and erecting the cartons. An F4 robot pre-groups the incoming labeled clamshell trays and transports them to the loading station. Once inserted into the cartons, a label is applied and the carton is securely closed.