#SuccessStory #AutoInjectors #Syringes #Vials Two-in-One Solution: Thermoforming and Cartoning Integrated

- Fast format change

- Compact design

- High line efficiency

- Transmodul ensures seamless transport

- Reduced manual documentation and faster batch changes through automated line clearance

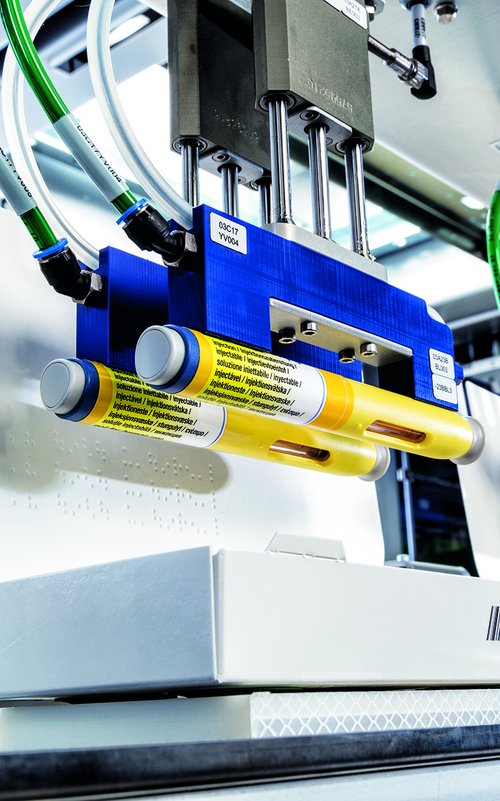

- Auto-injectors in 1-, 3-, 4-, 6-, and 12-pack configurations at speeds of 80–240 injectors per minute

- 4-, 6-, 10-, and 12-fold cartons with syringe blisters at a constant speed of 80 blisters per minute

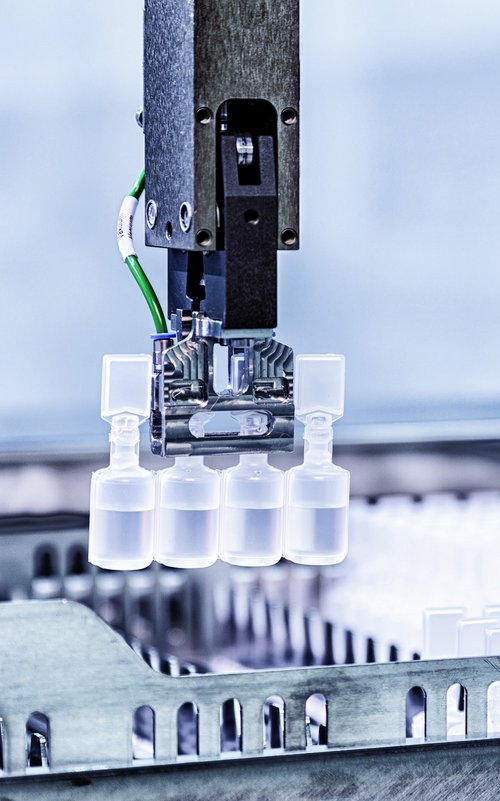

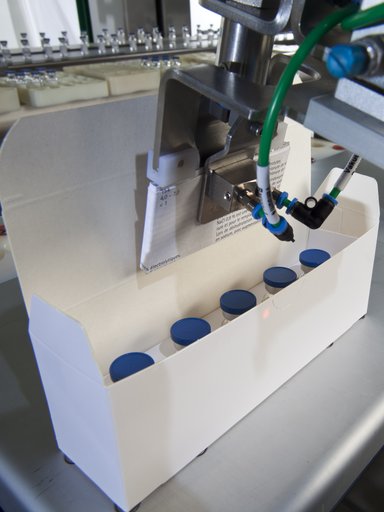

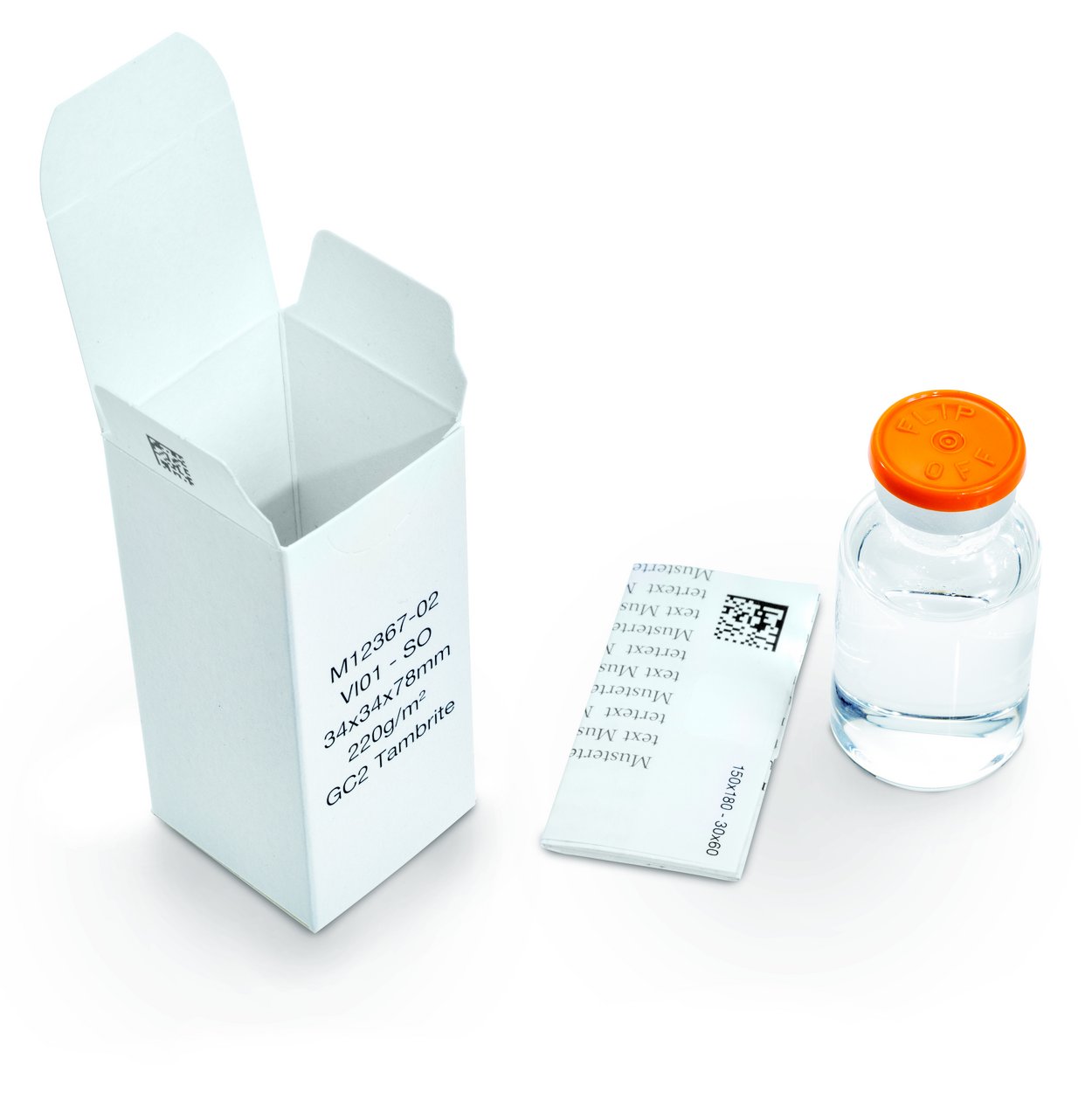

- Various vial sizes: Vials in 1-, 2-, and 10-pack configurations, upright or lying in trays

- Vial formats from 2R to 250H and combination packs of two different vial sizes

12

Packaging Formats

240

Injectors per minute

Requirement

Maximum productivity with optimal flexibility.

The combination of thermoforming and cartoning is usually implemented on two separate machines. Schubert-Pharma integrated these processes efficiently and space-saving for its customer, IDT Biologika, in a single system.

Increasing packaging complexity, changing ordering patterns of clients, and the trend toward smaller batch sizes created new demands for manufacturing technology. As a result, IDT Biologika sought a new production strategy for its packaging operations – and found the right partner in Schubert-Pharma.

Solution

The packaging tasks at IDT include packing and cartoning a wide variety of vials, blistered syringes, combination packs of syringes and vials, as well as medical devices in thermoformed trays. Schubert-Pharma successfully developed an efficient system capable of handling these diverse applications and formats.

Despite the complexity, the machine remains very compact, ensuring ease of operation. Since IDT Biologika packages different products on the same line, special attention is paid to line clearance – the process of removing all remaining packaging materials and excess products from the system. This process is fully automated, saving the customer significant time and substantially increasing overall system availability.

“What convinced us was the fact that we could realize all the required processing steps with a single line. Other suppliers were unable to offer a system concept in which all necessary capabilities were provided in one machine by a single manufacturer.”

Karin Kleinbach, Sales Director Pharma

Schubert Packaging Systems GmbH

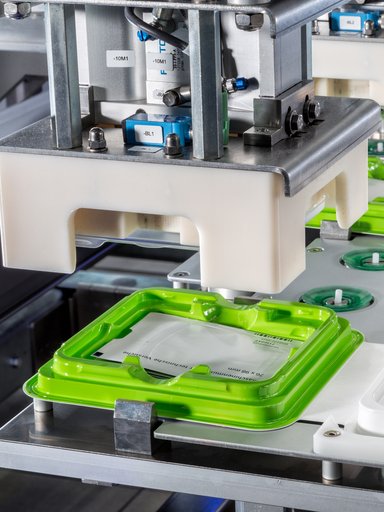

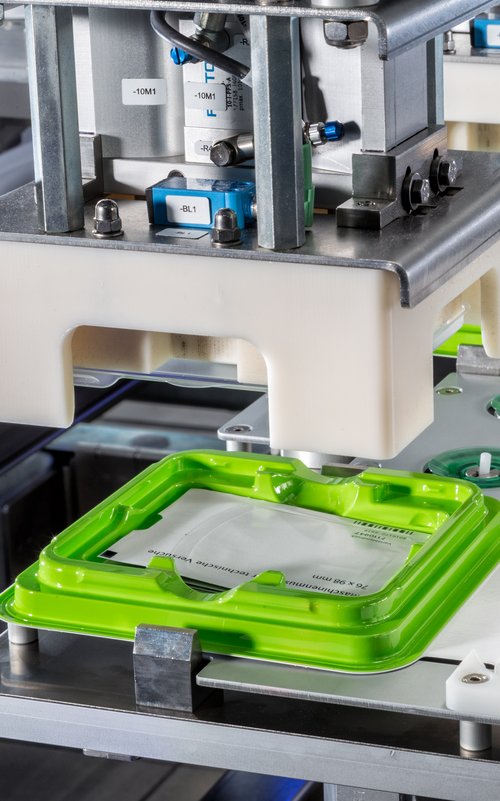

Thermoforming and Loading

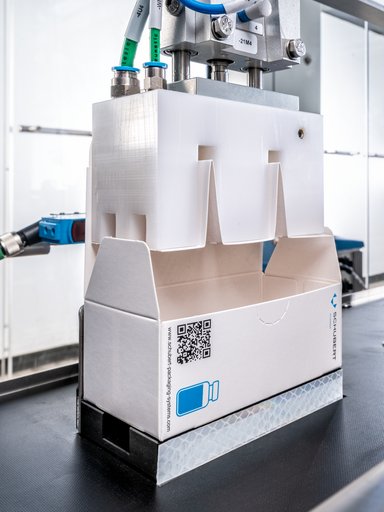

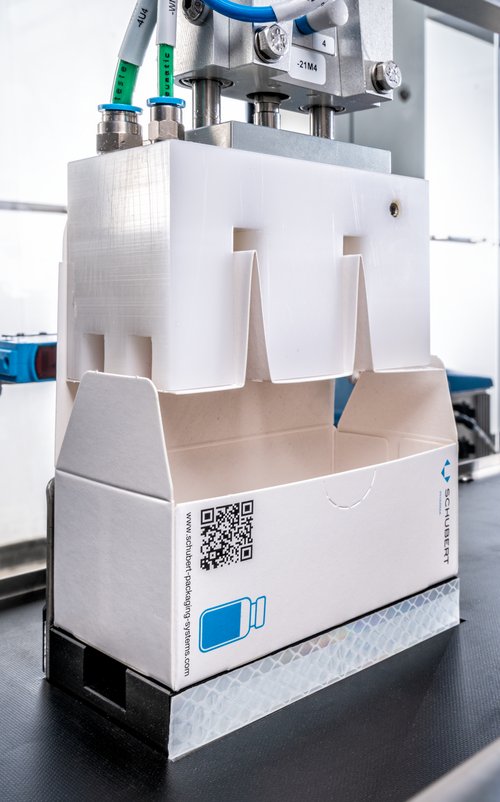

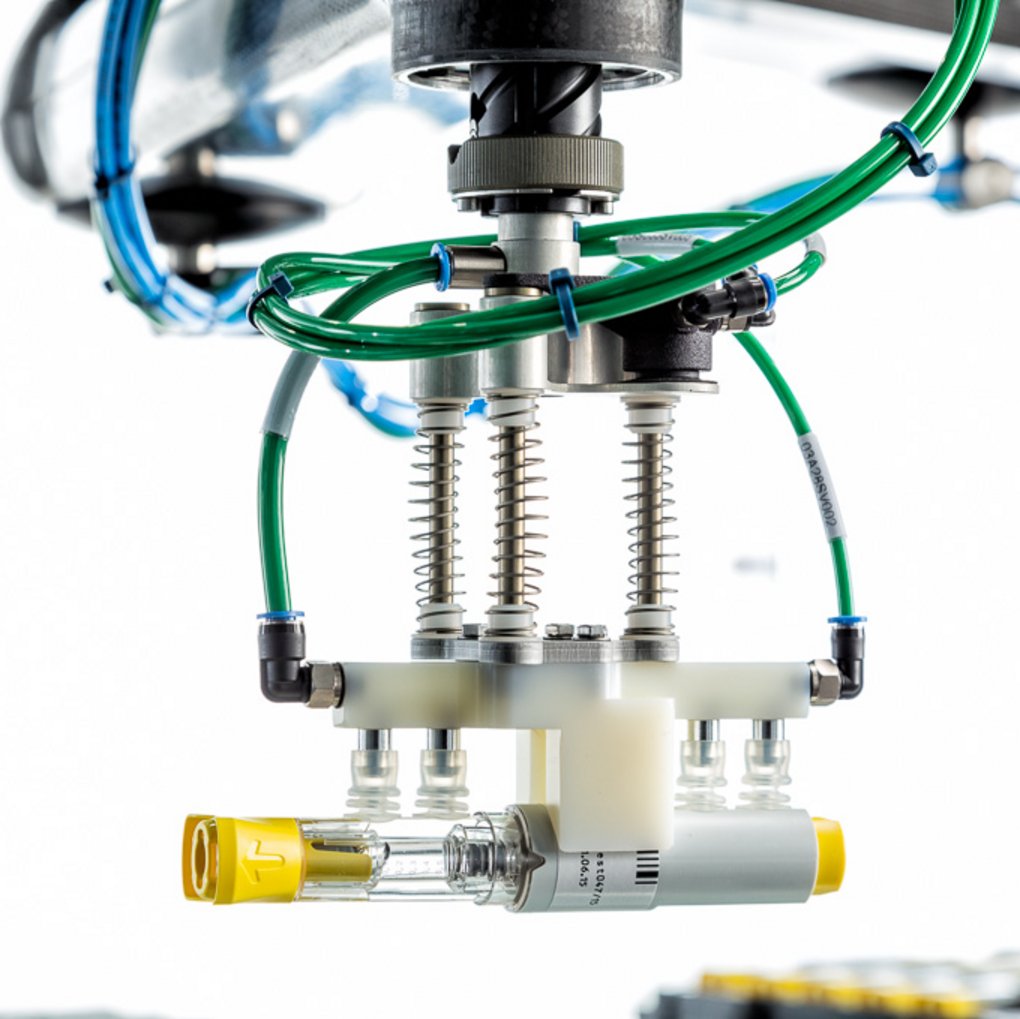

During the packaging of the devices, the thermoformed trays are first produced in Schubert’s thermoforming module. Unlike comparable solutions, a mother tray with a defined number of individual trays is formed initially and only separated later in the process. Product grouping already takes place on Transmodules with the help of F4 robots in the product feed area.

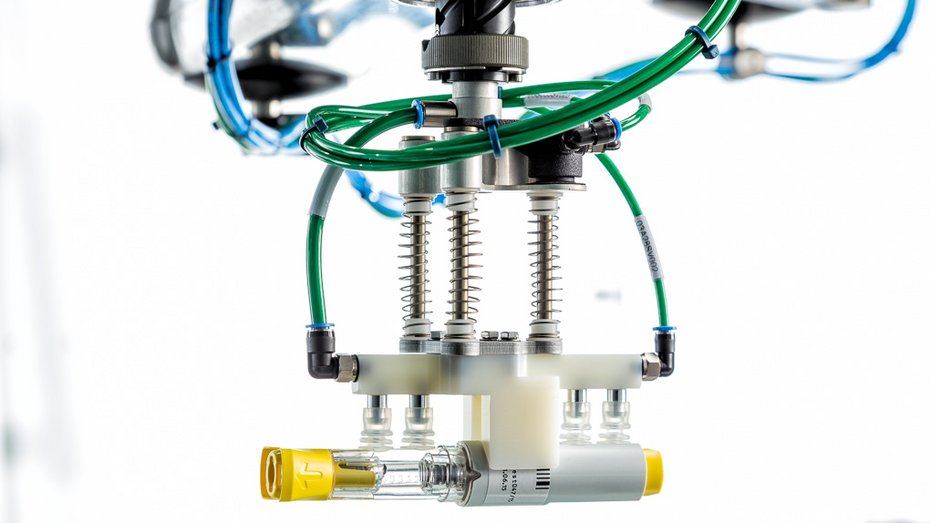

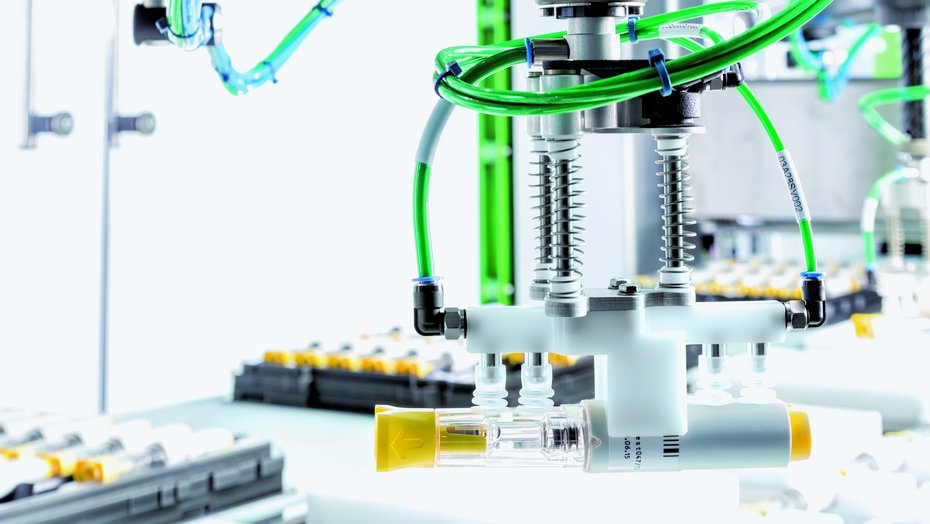

Above the product conveyor, a vision scanner detects the position and quantity of the products in the incoming trays and transmits this information to the F4 robots. The robots then pick up the individual products and place them precisely into the thermoformed trays.

Cartoning and Line Clearance

Next, the filled thermoformed trays are separated by punching and loaded into a top-load carton. The vials are transferred upright via a rotary table or a conveyor past the labeler and then onto the product conveyor. This conveyor is positioned within the working area of the F4 robots, allowing the same robots that handle the devices to also pre-group the vials.

Line clearance is managed through Schubert’s proprietary VMS packaging machine control system. A series of acknowledgments and cross-checks ensures that no products from the previous production run remain in the line. A sensor automatically verifies that all conveyors are empty and communicates this status directly to the machine operator.