#SuccessStory #Vials Efficient vial packaging into cartons

- Packaging vials into cartons with inserts: 1ct up to 50ct

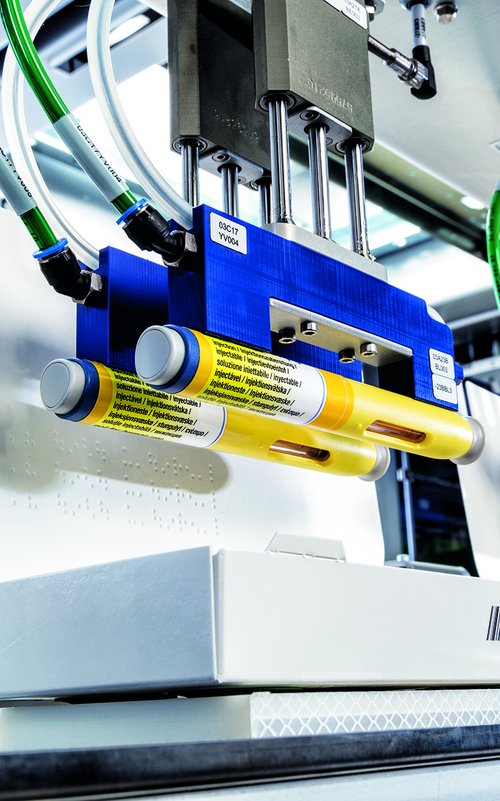

- Handling of single vials and combination packs

- Full project management including all preparations and related services

- Development of packaging materials including carton design

- Cross-contamination prevention via camera inspection

- Product feed either offline or inline from the labeler

20

Formats

400

Products per minute

Requirement

Over 20 formats packaged safely:

The packaging machine designed and supplied by Schubert-Pharma enables the customer to achieve the desired product variety.

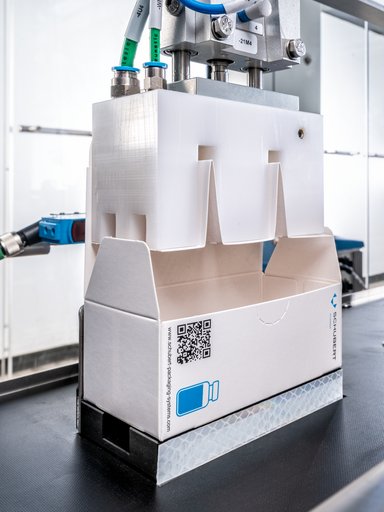

From 1ct cartons with side openings up to 50ct cartons with inserts – the machine delivered by Schubert-Pharma provides the customer with maximum flexibility.

Solution

For the Russian customer R-Pharm, the Schubert-Pharma team developed a flexible packaging line capable of handling more than 20 different formats. In addition, the packaging specialist worked closely with the customer to implement all packaging materials, including carton design.

The machine already demonstrates its flexibility at the component feeding stage, as products can be supplied from the labeler either offline or inline. An important feature is the cross-contamination control, which is ensured via a camera. All data is read back and fully managed throughout the process.

“We were very pleased with the comprehensive consulting. The completed system demonstrates that the collaboration worked perfectly, as it delivers exactly the technological edge we aimed to achieve.”

Alexei Repik, Owner and Managing Director

R-Pharm

Feeding Vials and Preparing Cartons

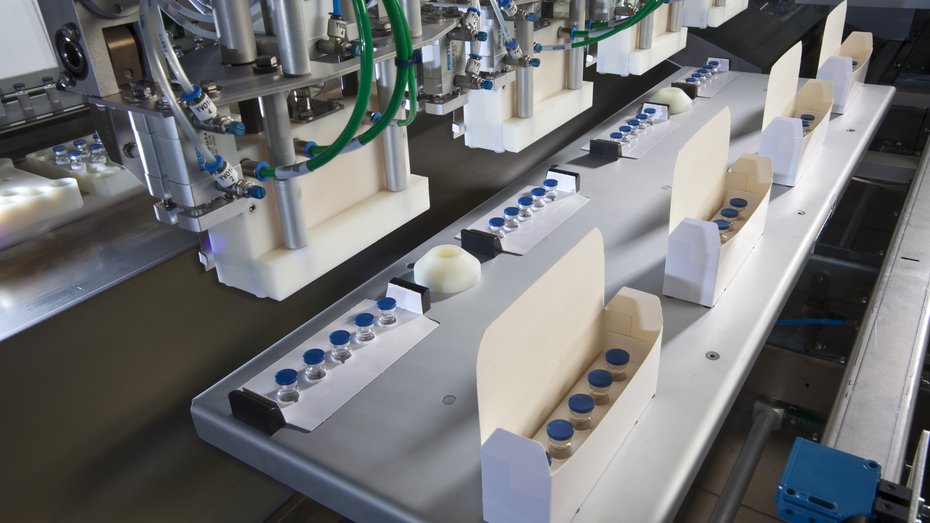

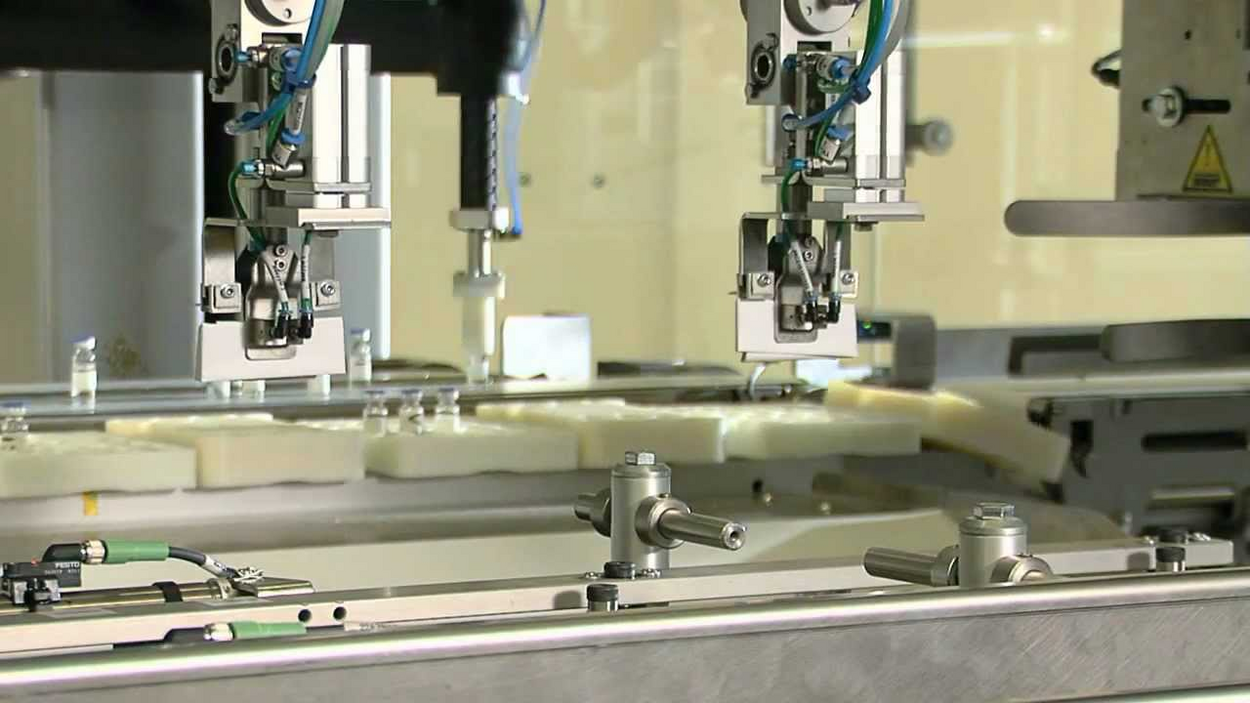

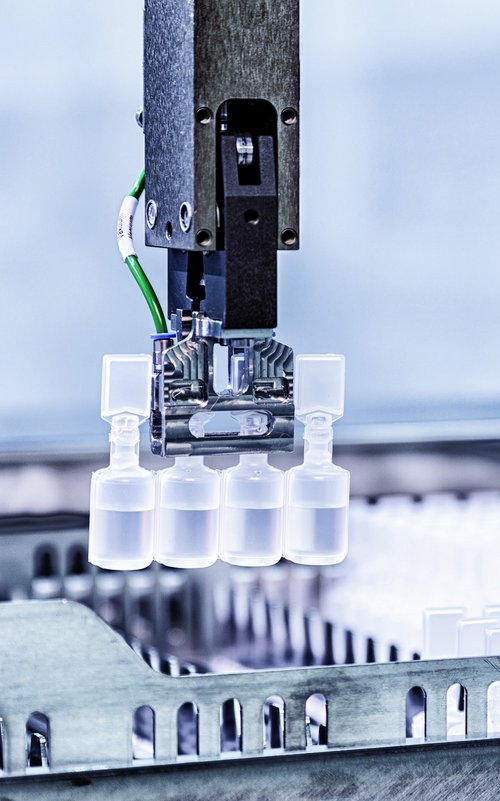

The labeler can feed products to the machine either offline or inline. The vials enter the machine upright on a continuously running feed conveyor. Four F4 robotic arms pick up the vials and place them onto a grouping conveyor, which can accommodate vials of any diameter.

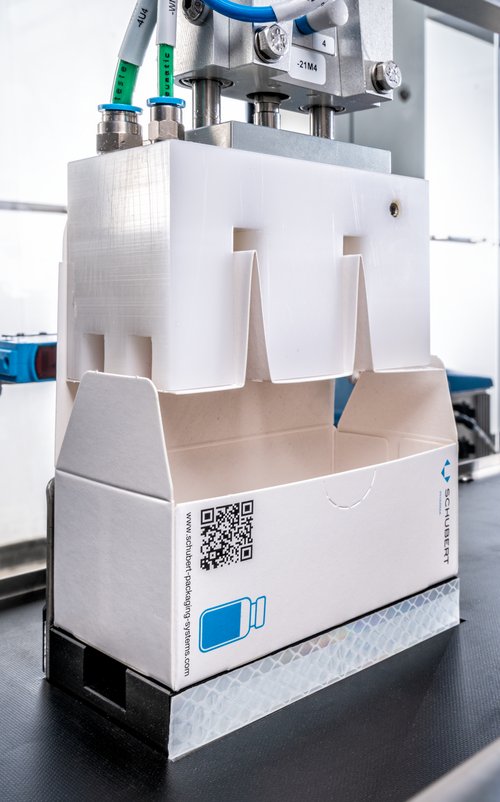

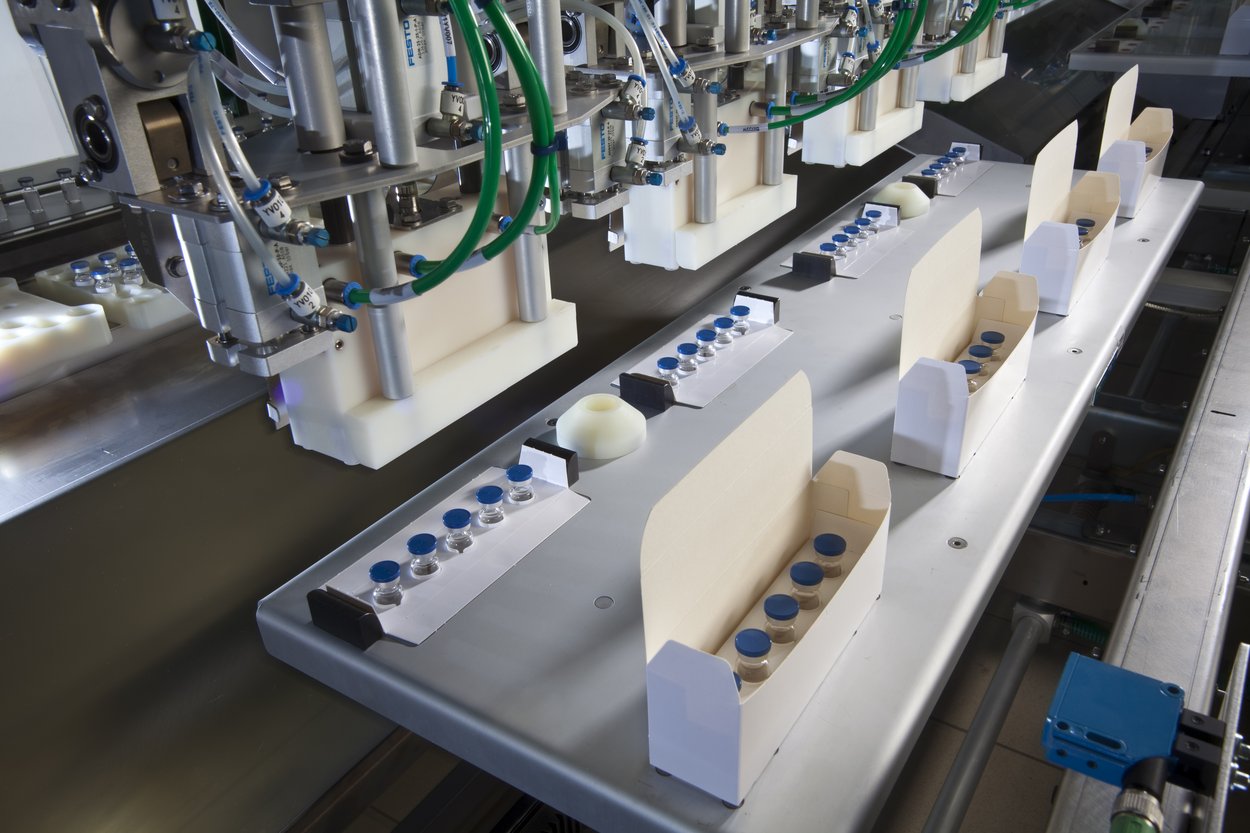

The second module is a carton erecting and gluing machine. It picks flat carton blanks from multi-lane magazines, erects them, and positions them onto Transmodul vacuum plates.

The third module is an insert station for partitions, which are also taken from multi-lane magazines and placed onto the Transmodul vacuum plates.

Filling and Sealing Cartons

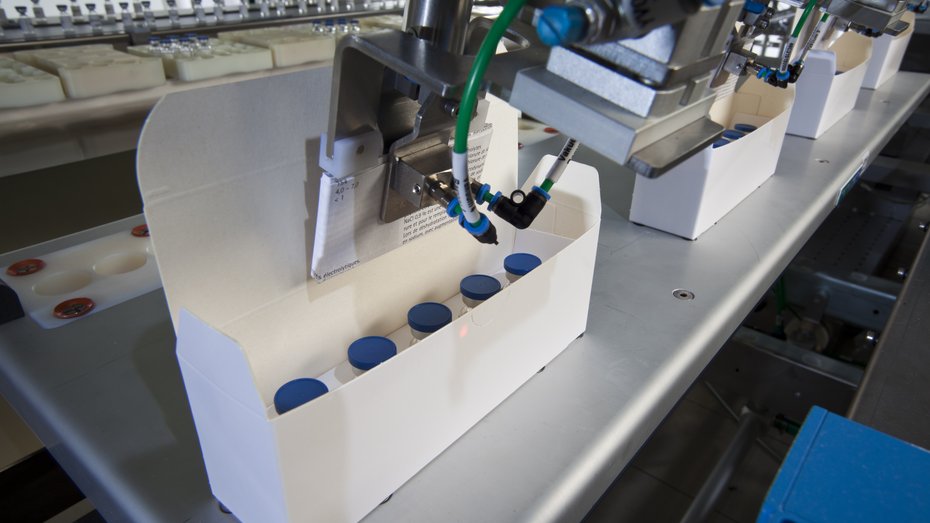

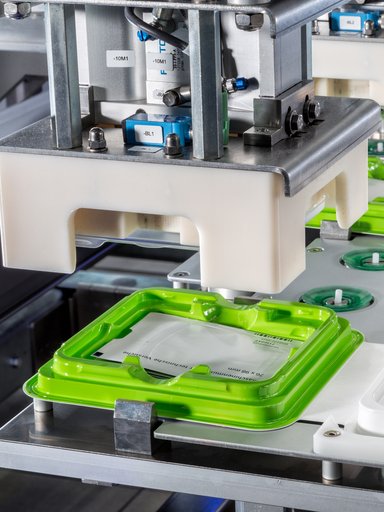

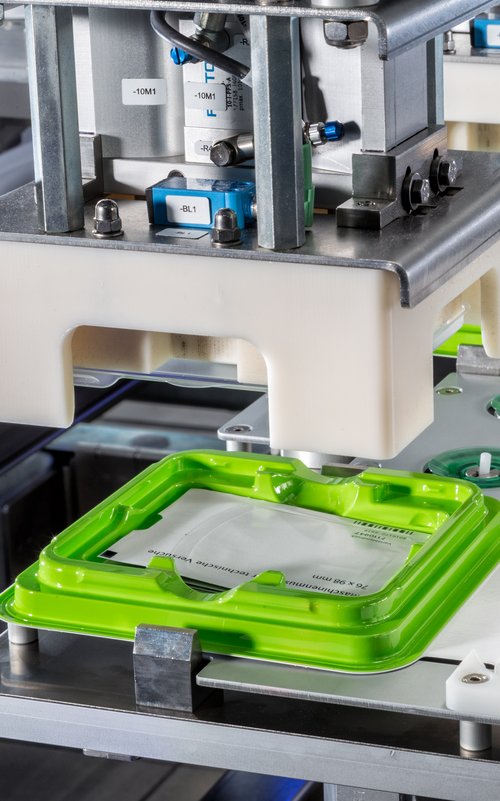

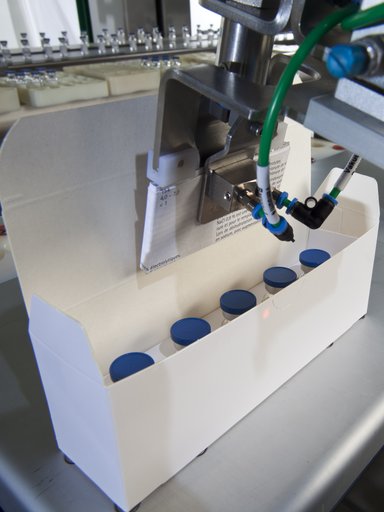

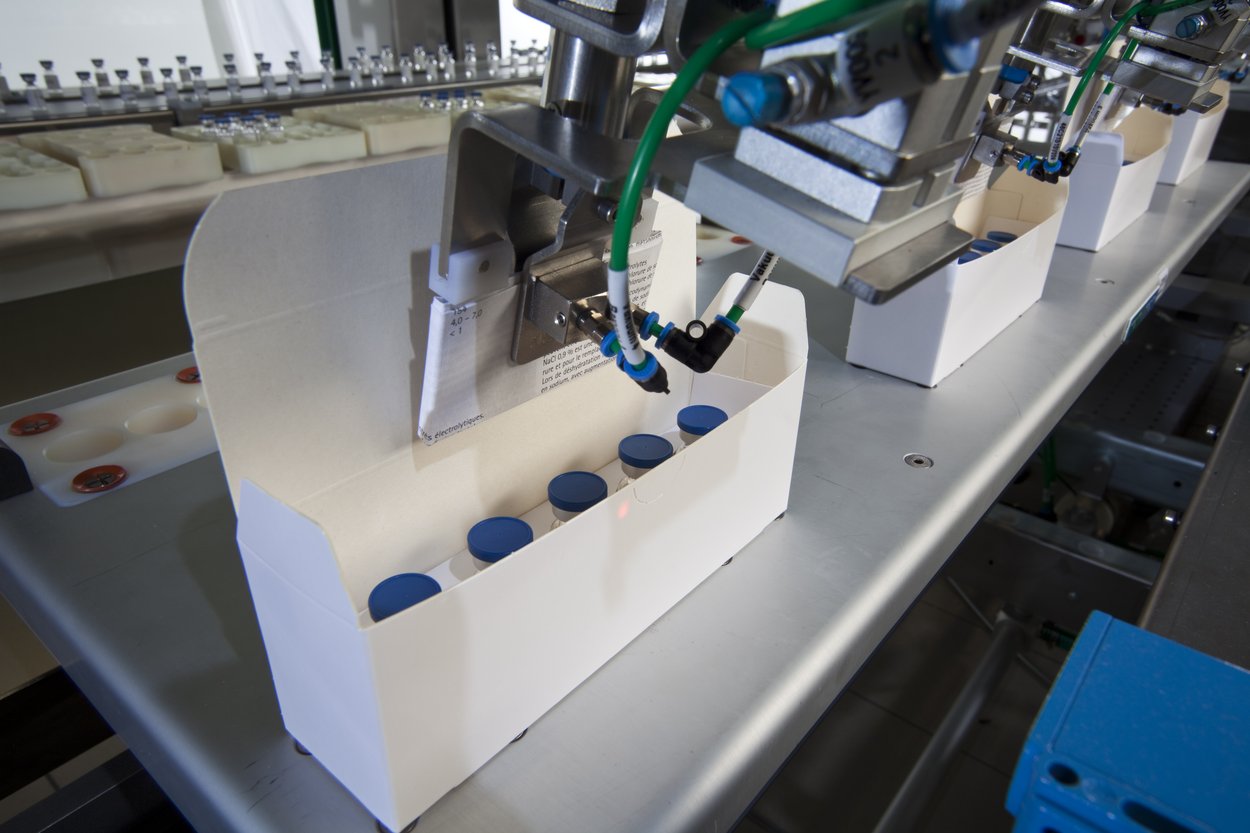

In the fourth module, an F2 robot equipped with a dedicated loading tool picks up the vials from the grouping conveyor. It places them into the inserts, which are then positioned inside the carton along with the vials.

Leaflets are fed from GUK dispensers into a step chain, transported to the closing station, and inserted into the carton during the sealing process.

The closing module is equipped with a magazine for separate lid components, which can be set up as needed for future formats.