#SuccessStory #BFS Products Two packaging lines – four individual machines

- Project management including all preparations and associated services

- Development of a new separation technology for BFS blocks

- Development of new packaging materials

- Design of sterilization trays and autoclave sterilization

- Line management system with integrated track-and-trace functionality

- Compact machine layout

- High line efficiency

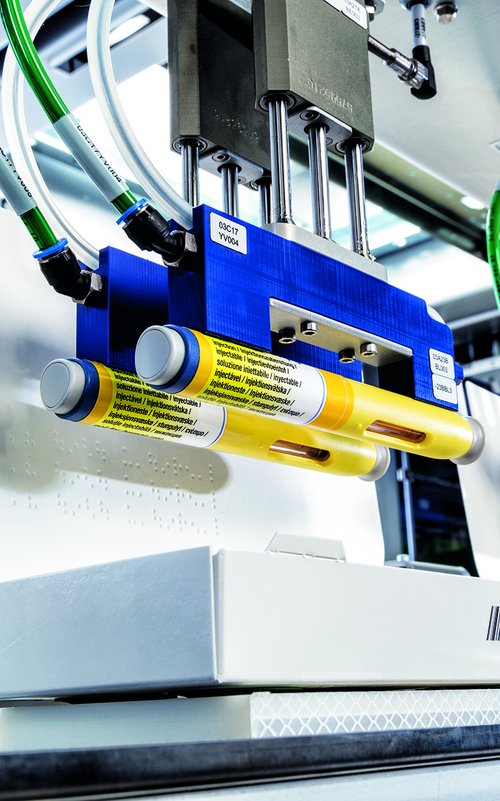

Shrink sleeve application prior to carton packing

530

Ampoules per minute

9 Mio.

Ampoules per machine

and month

Requirement

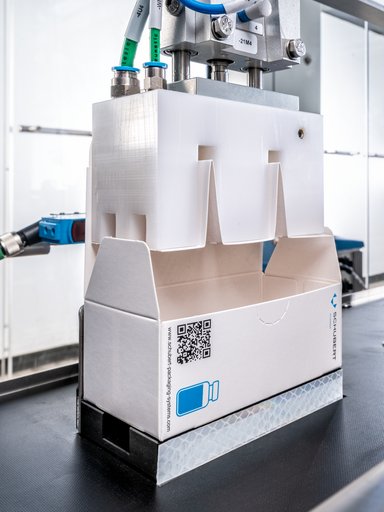

At its new production site, Nephron planned to package a new product: an injectable solution filled in a new type of vial – switching from polyethylene to polypropylene for the first time. Nephron had no prior experience handling this product in a secondary packaging line. Additionally, the products had to be sterilized in an autoclave – another process step that was new to the company. Unlike other Nephron products, the vials were to be labeled with a shrink sleeve before carton packing, rather than using a pre-labeled bag or a separate label.

Solution

Nephron placed a high value on the expertise of a partner in consulting and project management. Schubert-Pharma quickly proved to be the ideal partner, helping Nephron develop the new functionalities of the line.

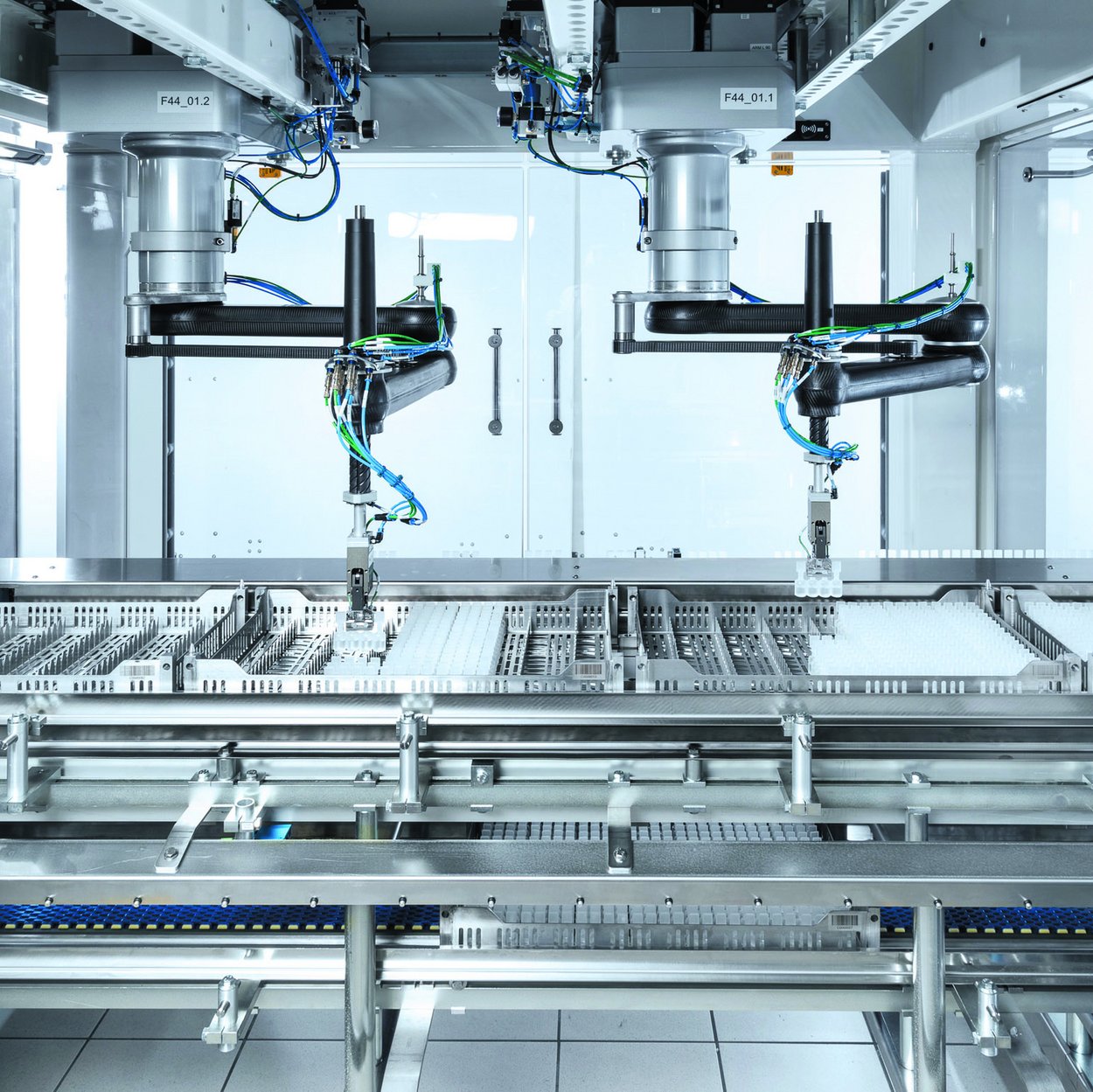

In addition, Schubert-Pharma provided guidance for implementing each individual process step. The team delivered two complete packaging lines, each comprising four standalone machines: a tray loader, product separator, cartoner, and casepacker. All functional components are based on the TLM modular system, once again demonstrating its exceptional performance.

“Both the products and certain process steps, such as sterilization, were entirely new to us. We were therefore looking for a competent partner to guide us through the entire process and assist in selecting the right tools. Schubert-Pharma fulfilled this role exemplary.”

Jonathan Burgess, R&D Engineer

Nephron

Tray Loader and Product Separator

TLM Tray Loader

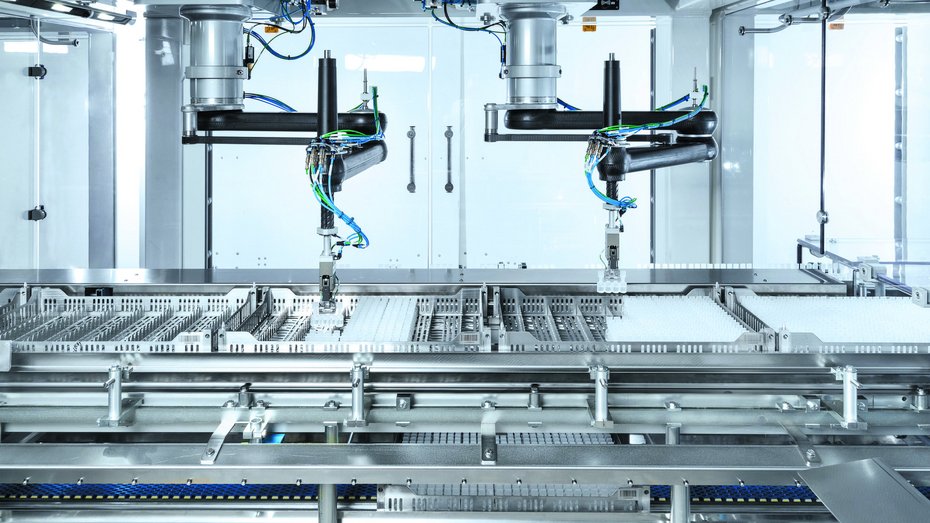

In the first machine, the Blow-Fill-Seal (BFS) blocks are transferred from the primary machine and sorted into sterilization trays. The trays are supplied using a P4 depalletizing/palletizing robot. Product handling is performed by F4 pick-and-place robots, which allows future product sizes to be processed without extensive format adjustments. The completed product pallets are automatically prepared for the next process step, sterilization in the autoclave.

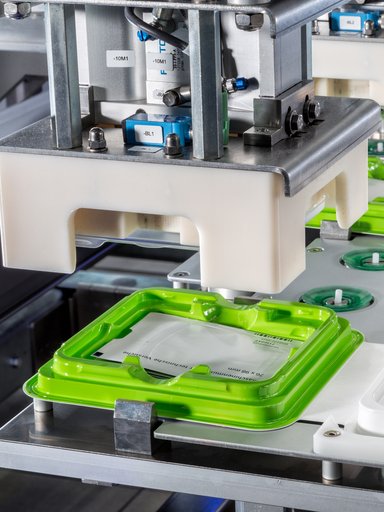

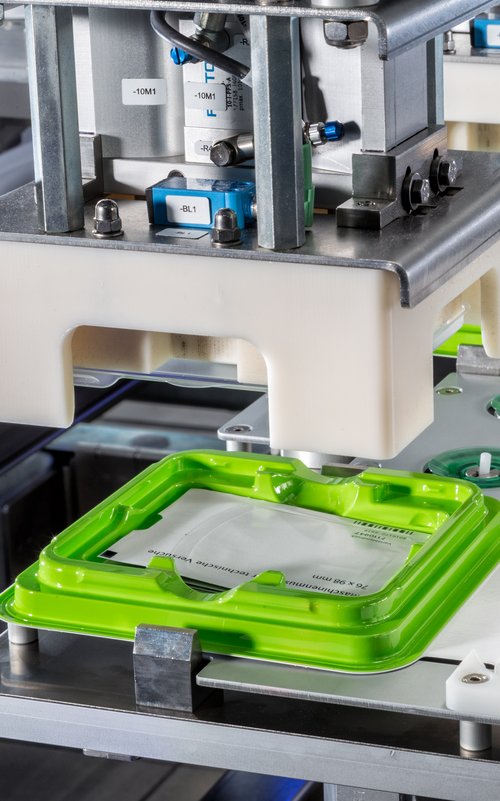

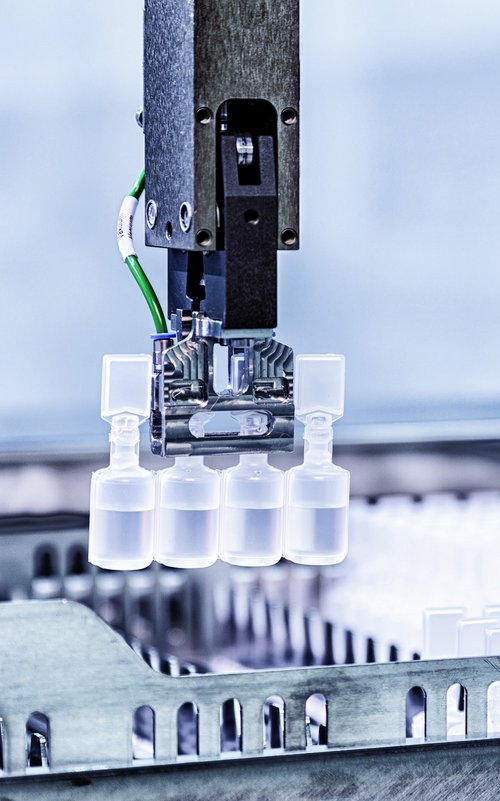

TLM Product Separator

After autoclaving, the sterilization trays are depalletized and prepared for product extraction in a second step. The BFS blocks are removed row by row from the trays and placed directly into the separation station. A gentle shearing motion of the separation tool ensures that the ampoules are separated without risk of tearing. A second F2 robot then picks the separated products from the separation station.

A key feature of this process step is not only the gentle separation, but also that the products are placed upside down into product carriers—so-called PUKs. Sensors check the trays for “empty status” and prepare them for repalletizing. In the loading and unloading area, a complete autoclave batch can be handled.

In two subsequent intermediate steps, the products undergo a leak test (vacuum check) and are then fitted with a shrink sleeve.

Cartoner, Case Packer, and Track-and-Trace System

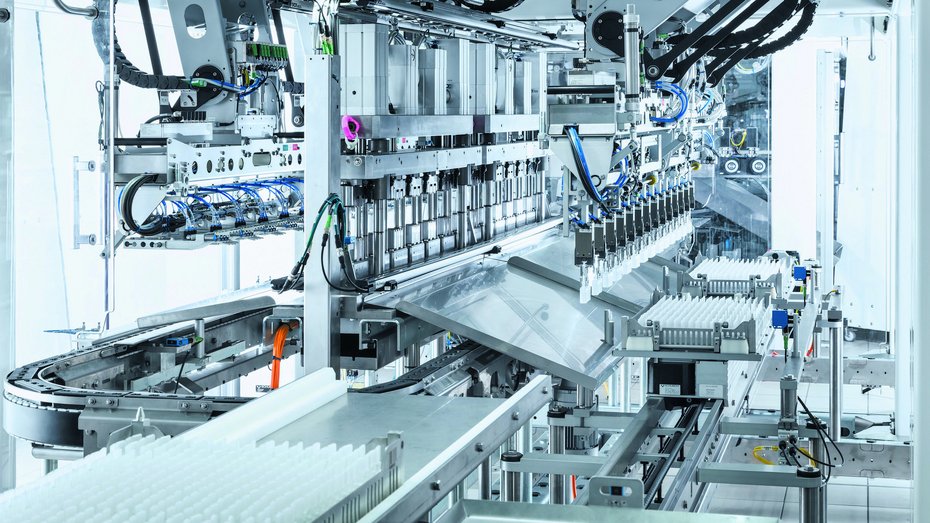

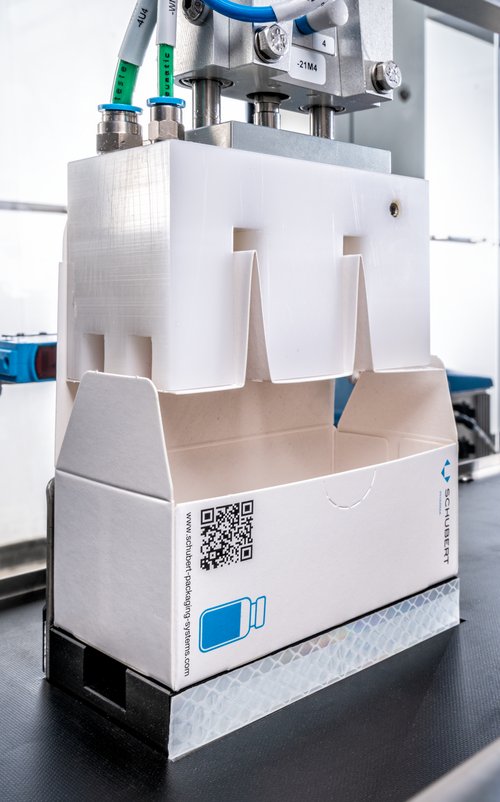

TLM-Cartoner

The Topload cartoner is the ideal solution for packing “upright” ampoules with varying heights and different quantities per carton.

A key feature of the cartoner is the product handling: in a “shake-hand” step, products are removed from the carriers and handed over to a second TLM-F2 robot. During this transfer, the products are rotated 180° and delivered to the loading robot in the desired orientation. The loading robot then spreads the product row to achieve the required number of ampoules per row in the carton. Before closing, an instruction leaflet is placed inside each carton. The finished cartons are then passed to the subsequent case packer.

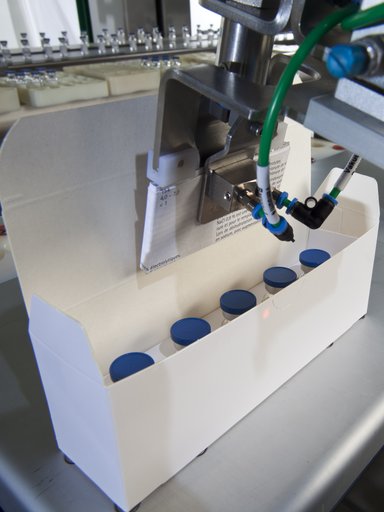

TLM- Case Packer

In the final TLM machine, the product cartons are inserted into a Fefco shipping carton. The case packer accommodates all common carton closure types according to Fefco standards, from AFM cartons to glued closures, or, with optional add-ons, tape closures. A noteworthy feature is the integrated label applicator with corner-wrapping capability. Fully completed, the shipping carton leaves the packaging line for central palletizing and warehouse logistics.

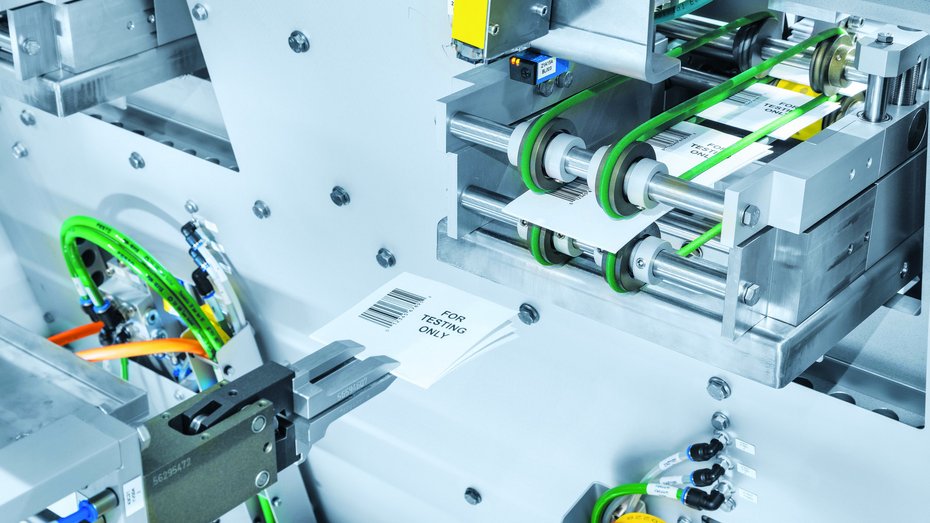

LMS and Track-and-Trace System

Schubert-Pharma designed and delivered an intelligent Line Management System (LMS) with integrated Track-and-Trace functionality for the entire line. This system manages all batch data and links it to the product trays. Batch data is tracked throughout the packaging process and assigned to specific orders. The system receives randomized serial data from a higher-level data control system, applies it to the product carton, aggregates it into the shipping carton, and communicates the information back to the MES system at the production site.