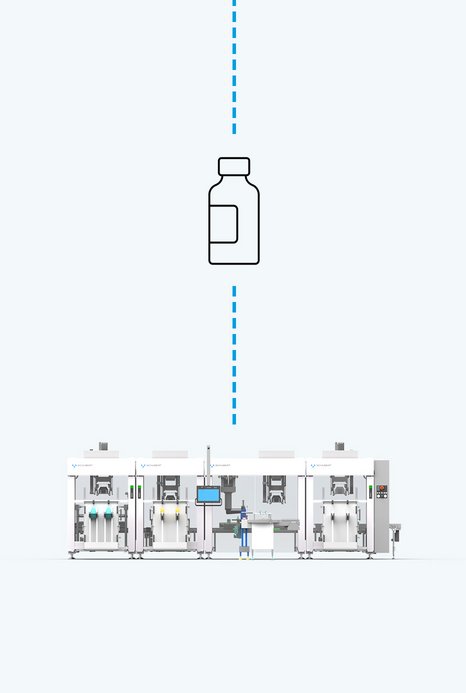

Bottle packaging

- Flexible handling of glass and plastic bottles

- Can be combined with dosing aids, inserts, or labels

"Secure placement into trays, partitions or folding cartons

- High line availability thanks to robust robotics

- GMP-compliant implementation for pharmaceutical standards

Special features of bottles

Pharmaceutical bottles need to be grouped and often supplemented with dosing aids or package inserts. Our top-loading technology ensures precise placement—even with different bottle and closure types.

1. Infeed: Bottles

1. Infeed: Bottles

The bottles are fed into the machine from the upstream process in a single lane. A TLM-F4 robot picks up the products and transfers them onto a Transmodul.

2. Erect: Cartons

2. Erect: Cartons

The flat blanks are stored in two magazines. Two TLM-F3 robots pick up the respective flat blanks from the magazines and hand them to the TLM-F2 robot. The TLM-F2 robot passes the blank over the glue nozzles. Sensors check the code on the folding carton. If successfully read, the blank is pressed through a forming die, erecting the carton and placing it onto a Transmodul.

3. Infeed / Fold / Fill: Leaflet

3. Infeed / Fold / Fill: Leaflet

A TLM-F3 robot picks up the package inserts from a magazine and hands them to the TLM-F2 robot. The TLM-F2 robot folds the inserts and places them on an intermediate table.

4. Fill: Bottles

4. Fill: Bottles

A TLM-F2 robot takes the erected cartons from the Transmodul and places them onto a vacuum conveyor. Another TLM-F2 robot picks up the bottles from the other Transmodul and inserts them into the erected cartons.

5. Close: Carton

5. Close: Carton

Another TLM-F2 robot folds in the side flaps and seals the carton.

6. Discharge: Carton

6. Discharge: Carton

At the end, a TLM-F2 robot transfers the sealed and inspected carton onto the discharge conveyor, and it leaves the machine in a single lane.

7. Discharge

7. Discharge

The machine is equipped with multiple defined reject stations. Depending on the type of error, the product, the blank, the leaflet, or even an already packaged bottle or a defective carton can be selectively rejected.

Facts about the

Bottle Cartoner

From a customer project:

- 200 bottles per minute

- 2 bottle sizes (50 ml / 100 ml)

- 10 packaging configurations

- Format changeover within 5–20 minutes

- Additional Schubert process steps: product labeling, case packing and palletizing

- Comprehensive integration into the customer’s MES (Manufacturing Execution System)

- Serialization integrated

Questions about

Bottle packaging?

Contact

Nurdan Aktas

Sales Assistant Pharma

Phone +49 7951 494-20

info@schubert-pharma.com